What to Know About 4 Color Screen Printers for Custom Apparel

Benefits of Using 4 Color Screen Printers for Custom Apparel

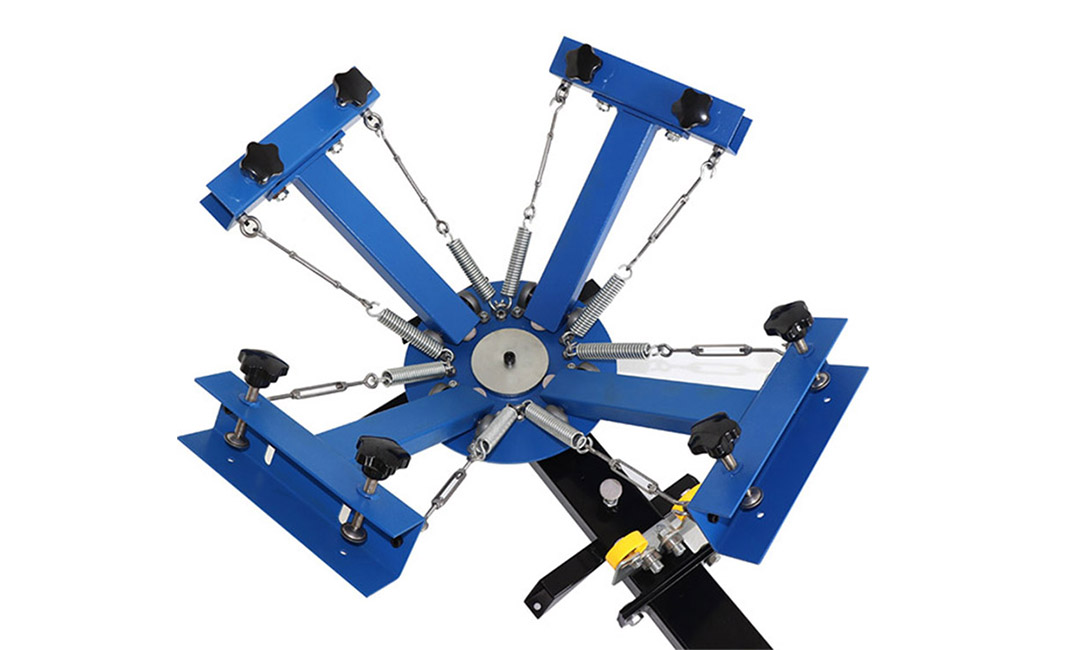

Custom apparel has become increasingly popular in recent years, with more and more individuals and businesses looking to create unique and personalized clothing items. One of the most common methods used to create custom apparel is screen printing, and 4 color screen printers have become a popular choice for those looking to create high-quality, vibrant designs on their clothing items.

There are several benefits to using 4 color screen printers for custom apparel. One of the main advantages is the ability to create designs with a wide range of colors. Traditional screen printing methods are limited to a small number of colors, but with 4 color screen printers, you can create designs with up to four different colors. This allows for more intricate and detailed designs, as well as the ability to create designs with a greater range of colors.

Another benefit of using 4 color screen printers is the ability to create designs with a high level of detail and precision. The four color process allows for finer lines and more intricate designs to be printed onto clothing items, resulting in a more professional and polished finished product. This is especially important for businesses looking to create custom apparel for promotional purposes, as a high-quality design can help to enhance brand visibility and recognition.

In addition to the ability to create designs with a wide range of colors and high levels of detail, 4 color screen printers also offer a high level of durability. The inks used in the printing process are designed to withstand regular wear and tear, ensuring that the designs on your custom apparel will remain vibrant and intact for a long time. This is particularly important for businesses looking to create custom apparel for employees or customers, as it ensures that the clothing items will continue to promote the brand for an extended period.

Furthermore, 4 color screen printers are versatile and can be used to print on a wide range of materials. Whether you are looking to create custom t-shirts, hoodies, hats, or other clothing items, a 4 color screen printer can handle the job with ease. This versatility makes it a popular choice for businesses looking to create a variety of custom apparel items for different purposes.

Overall, 4 color screen printers offer a range of benefits for those looking to create custom apparel. From the ability to create designs with a wide range of colors and high levels of detail, to the durability and versatility of the printing process, there are many reasons why businesses and individuals choose to use 4 color screen printers for their custom apparel needs. If you are looking to create high-quality, vibrant custom apparel, a 4 color screen printer may be the perfect choice for you.

Tips for Choosing the Right 4 Color Screen Printer for Your Needs

When it comes to creating custom apparel, 4 color screen printers are a popular choice for many businesses and individuals. These printers allow for vibrant and detailed designs to be printed onto various types of clothing, making them a versatile option for those looking to create unique and eye-catching garments. However, with so many options available on the market, it can be overwhelming to choose the right 4 color screen printer for your needs. In this article, we will discuss some tips for selecting the best printer for your custom apparel projects.

One of the first things to consider when choosing a 4 color screen printer is the size of the printer. Depending on the size of your business and the volume of custom apparel you plan to produce, you may need a larger or smaller printer. Larger printers are ideal for high-volume production, while smaller printers are better suited for smaller runs or individual projects. Consider your production needs and choose a printer that can accommodate them.

Another important factor to consider when selecting a 4 color screen printer is the quality of the prints it produces. Look for a printer that offers high-resolution printing capabilities and vibrant colors. The quality of the prints will directly impact the overall look and feel of your custom apparel, so it is essential to choose a printer that can deliver crisp, clear designs.

In addition to print quality, it is also important to consider the durability of the printer. Look for a printer that is built to last and can withstand the demands of regular use. A durable printer will save you time and money in the long run, as you will not have to worry about frequent repairs or replacements.

When choosing a 4 color screen printer, it is also important to consider the ease of use. Look for a printer that is user-friendly and intuitive, with a simple interface that makes it easy to create and print designs. A printer that is easy to use will save you time and frustration, allowing you to focus on creating stunning custom apparel.

Another important consideration when selecting a 4 color screen printer is the cost. Prices for these printers can vary widely, so it is essential to set a budget and stick to it. Consider the initial cost of the printer, as well as any ongoing maintenance or supplies that may be required. While it may be tempting to opt for a cheaper printer, it is important to remember that quality and durability are key factors in choosing the right printer for your needs.

In conclusion, choosing the right 4 color screen printer for your custom apparel projects is essential for creating high-quality, eye-catching designs. Consider factors such as size, print quality, durability, ease of use, and cost when selecting a printer. By taking the time to research and compare different options, you can find a printer that meets your needs and helps you create stunning custom apparel for your business or personal projects.

Common Mistakes to Avoid When Using 4 Color Screen Printers for Custom Apparel

When it comes to creating custom apparel, 4 color screen printers are a popular choice for many businesses and individuals. These printers allow for vibrant and detailed designs to be printed onto various types of clothing, making them a versatile option for those looking to create unique and eye-catching garments. However, there are some common mistakes that can occur when using 4 color screen printers that can impact the quality of the final product. In this article, we will discuss some of these mistakes and how to avoid them to ensure that your custom apparel turns out exactly as you envisioned.

One of the most common mistakes that people make when using 4 color screen printers is not properly preparing the artwork before printing. This can lead to blurry or distorted images, as well as colors that do not match the original design. To avoid this, it is important to make sure that your artwork is high resolution and properly formatted for printing. This includes ensuring that the colors are separated correctly and that any text or logos are crisp and clear. Taking the time to properly prepare your artwork can make a big difference in the final outcome of your custom apparel.

Another common mistake that people make when using 4 color screen printers is not properly aligning the screens before printing. This can result in misaligned designs and colors that do not line up correctly. To avoid this, it is important to carefully align each screen before printing to ensure that the design is centered and straight. This can be done by using registration marks on the screens and making adjustments as needed before printing. Taking the time to properly align the screens can help to ensure that your custom apparel looks professional and polished.

In addition to proper artwork preparation and screen alignment, it is also important to use the right type of ink when printing with a 4 color screen printer. Using the wrong type of ink can result in colors that are dull or do not adhere properly to the fabric. To avoid this, it is important to use high-quality, opaque inks that are specifically designed for use with screen printers. These inks will provide vibrant colors and crisp designs that will last through multiple washings. It is also important to properly cure the ink after printing to ensure that it sets correctly and does not fade or crack over time.

Finally, one of the most common mistakes that people make when using 4 color screen printers is not properly maintaining the equipment. Regular cleaning and maintenance of your printer can help to prevent clogs, smudges, and other issues that can impact the quality of your prints. It is important to clean the screens, squeegees, and other components of the printer regularly to ensure that they are free of debris and ink buildup. Additionally, it is important to replace any worn or damaged parts as needed to keep your printer running smoothly.

In conclusion, using a 4 color screen printer for custom apparel can be a great way to create unique and eye-catching designs. However, there are some common mistakes that can occur when using these printers that can impact the quality of the final product. By properly preparing your artwork, aligning the screens, using the right type of ink, and maintaining your equipment, you can avoid these mistakes and ensure that your custom apparel turns out exactly as you envisioned. With a little attention to detail and care, you can create professional-looking custom apparel that will impress your customers and stand out from the crowd.

Pre: How to Keep Your Manual Screen Printing Press in Optimal Condition

Next: Tips for Effective Heat Curing to Ensure Vibrant and Durable Prints

Tags: