Unlock Perfect Alignment with a 4 Color 1 Station Screen Printing Press with Micro Registration

Benefits of Using a 4 Color 1 Station Screen Printing Press with Micro Registration

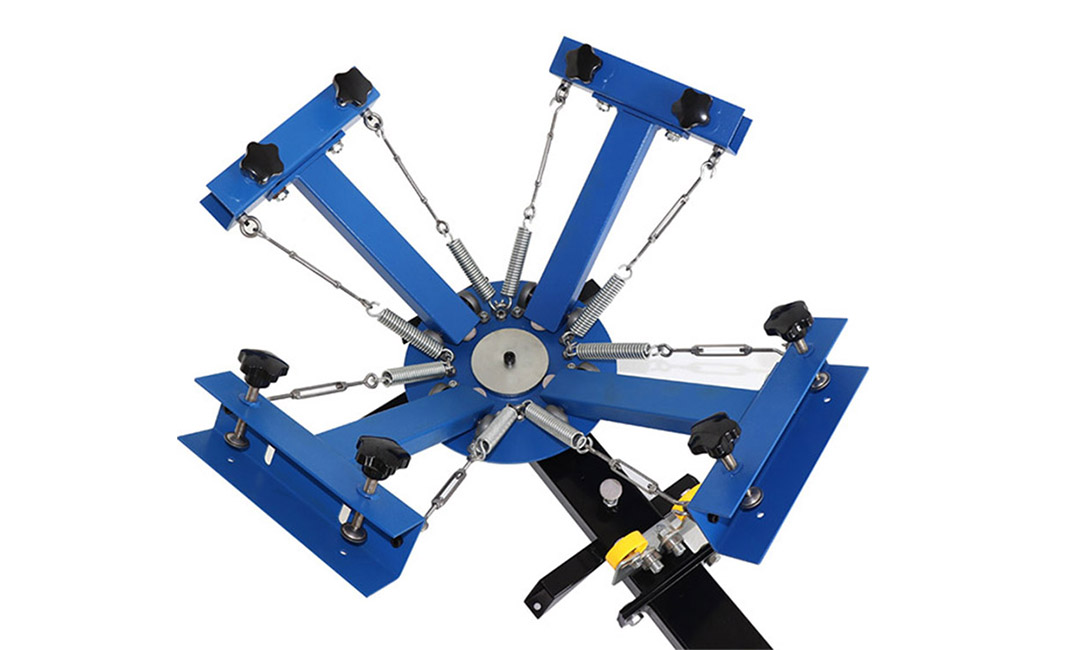

Screen printing is a popular method of printing that has been used for decades to create high-quality prints on various surfaces. One of the key components of screen printing is the screen printing press, which is used to hold the screens in place and apply the ink to the surface being printed on. A 4 color 1 station screen printing press with micro registration is a versatile and efficient tool that can help you achieve perfect alignment and precise prints every time.

One of the main benefits of using a 4 color 1 station screen printing press with micro registration is the ability to easily align multiple colors on a single print. With traditional screen printing presses, aligning multiple colors can be a time-consuming and challenging process. However, with a 4 color 1 station press with micro registration, you can easily adjust the position of each screen to ensure that all colors are perfectly aligned. This can help you create professional-looking prints with crisp, clean lines and vibrant colors.

Another benefit of using a 4 color 1 station screen printing press with micro registration is the ability to achieve consistent results. The micro registration system allows you to make precise adjustments to the position of each screen, ensuring that each print is identical to the last. This can be especially important when printing multiple copies of the same design, as it helps to maintain a high level of quality and consistency across all prints.

In addition to perfect alignment and consistent results, a 4 color 1 station screen printing press with micro registration can also help you save time and increase efficiency. The micro registration system allows you to make quick and easy adjustments to the position of each screen, reducing the amount of time spent on setup and alignment. This can help you complete printing jobs more quickly and efficiently, allowing you to take on more projects and increase your productivity.

Furthermore, a 4 color 1 station screen printing press with micro registration is a versatile tool that can be used for a wide range of printing applications. Whether you are printing t-shirts, posters, or other promotional materials, this type of press can help you achieve professional results with ease. The ability to print multiple colors in precise alignment opens up a world of creative possibilities, allowing you to create eye-catching designs that stand out from the competition.

Overall, a 4 color 1 station screen printing press with micro registration is a valuable tool for any screen printer looking to achieve perfect alignment, consistent results, and increased efficiency. Whether you are a seasoned professional or just starting out, this type of press can help you take your printing to the next level. With its versatility, ease of use, and ability to produce high-quality prints, a 4 color 1 station press with micro registration is a must-have tool for any screen printing operation.

Tips for Achieving Perfect Alignment with a 4 Color 1 Station Screen Printing Press

Screen printing is a popular method of transferring designs onto various surfaces, such as t-shirts, posters, and bags. One of the key challenges in screen printing is achieving perfect alignment when using multiple colors in a design. This is where a 4 color 1 station screen printing press with micro registration can be a game-changer.

The micro registration feature on a screen printing press allows for precise adjustments to be made to the position of each color screen. This level of control is essential for ensuring that each color in a design lines up perfectly with the others, resulting in a crisp and professional-looking print.

To unlock perfect alignment with a 4 color 1 station screen printing press with micro registration, there are a few tips and techniques that can help you achieve the best results. One of the most important things to keep in mind is the importance of proper setup and preparation.

Before you begin printing, make sure that each color screen is properly aligned on the press. This may involve adjusting the micro registration knobs to fine-tune the position of each screen. Take your time with this step, as it will have a significant impact on the final outcome of your print.

Once you have all of your screens aligned, it’s time to test your setup. Print a test run on a scrap piece of material to see how the colors line up. If adjustments need to be made, use the micro registration knobs to make small tweaks until you are satisfied with the results.

Another tip for achieving perfect alignment with a 4 color 1 station screen printing press is to use registration marks on your screens. These marks can help you line up each color screen accurately and consistently, ensuring that your design prints correctly every time.

When printing multiple colors, it’s also important to consider the order in which you print each color. Start with the lightest color and work your way up to the darkest color. This will help prevent any bleeding or smudging of colors and ensure a clean and vibrant print.

In addition to proper setup and printing techniques, it’s also essential to use high-quality materials when screen printing. Invest in good quality inks, screens, and squeegees to achieve the best results. Using inferior materials can lead to poor alignment and overall print quality.

Finally, practice makes perfect when it comes to achieving perfect alignment with a 4 color 1 station screen printing press. Take the time to experiment with different techniques and settings to find what works best for you. With patience and persistence, you can unlock the full potential of your screen printing press and create stunning prints with perfect alignment.

In conclusion, a 4 color 1 station screen printing press with micro registration is a valuable tool for achieving perfect alignment in your screen printing projects. By following these tips and techniques, you can unlock the full potential of your press and create professional-quality prints with ease. Practice, attention to detail, and high-quality materials are key to achieving perfect alignment and producing outstanding results in your screen printing endeavors.

Step-by-Step Guide to Setting Up and Using a 4 Color 1 Station Screen Printing Press with Micro Registration

Screen printing is a popular method of printing designs onto various surfaces, such as t-shirts, posters, and bags. One of the key components of screen printing is the screen printing press, which holds the screen in place and allows for precise alignment of the design. A 4 color 1 station screen printing press with micro registration is a versatile and efficient tool that can help you achieve perfect alignment in your prints.

Setting up a 4 color 1 station screen printing press with micro registration may seem daunting at first, but with the right guidance, it can be a straightforward process. To begin, make sure you have all the necessary equipment and supplies on hand, including screens, squeegees, ink, and a registration template. Once you have everything you need, follow these steps to set up your screen printing press.

First, assemble the screen printing press according to the manufacturer’s instructions. Make sure all the components are securely in place and that the press is stable and level. Next, attach the screens to the press using the appropriate clamps or brackets. Make sure the screens are taut and evenly stretched to ensure a clean print.

Once the screens are in place, it’s time to set up the micro registration system. This system allows for precise adjustments to the position of each screen, ensuring perfect alignment of the colors in your design. Start by adjusting the micro registration knobs on each screen to bring them into alignment with the registration template. Take your time with this step, as small adjustments can make a big difference in the final print.

After the screens are aligned, it’s time to prepare the ink. Place a small amount of ink on the screen and use a squeegee to spread it evenly across the design. Make sure the ink is evenly distributed and that there are no gaps or streaks in the print. Once the ink is applied, lift the screen and inspect the print to ensure it meets your standards.

Once you are satisfied with the print, repeat the process for each color in your design. Use the micro registration system to make any necessary adjustments to the position of the screens between prints. Take your time with each color to ensure that they are all perfectly aligned and that the final print is crisp and clean.

Using a 4 color 1 station screen printing press with micro registration can help you achieve professional-quality prints with ease. By following these steps and taking your time to set up and align the screens, you can unlock perfect alignment in your screen prints. Experiment with different colors and designs to create unique and eye-catching prints that will impress your customers and clients.

In conclusion, a 4 color 1 station screen printing press with micro registration is a valuable tool for any screen printer looking to achieve perfect alignment in their prints. By following a step-by-step guide to setting up and using this press, you can unlock the full potential of your screen printing projects and create stunning prints that will stand out from the crowd.

Pre: 4 Color 1 Station Silk Screen Printing Machine: Tips for Beginners

Next: Riley Hopkins 4 Color 1 Station: A Reliable Choice for Screen Printers

Tags: