Understanding Platen Size and How It Affects Screen Printing Results

Importance of Platen Size in Screen Printing

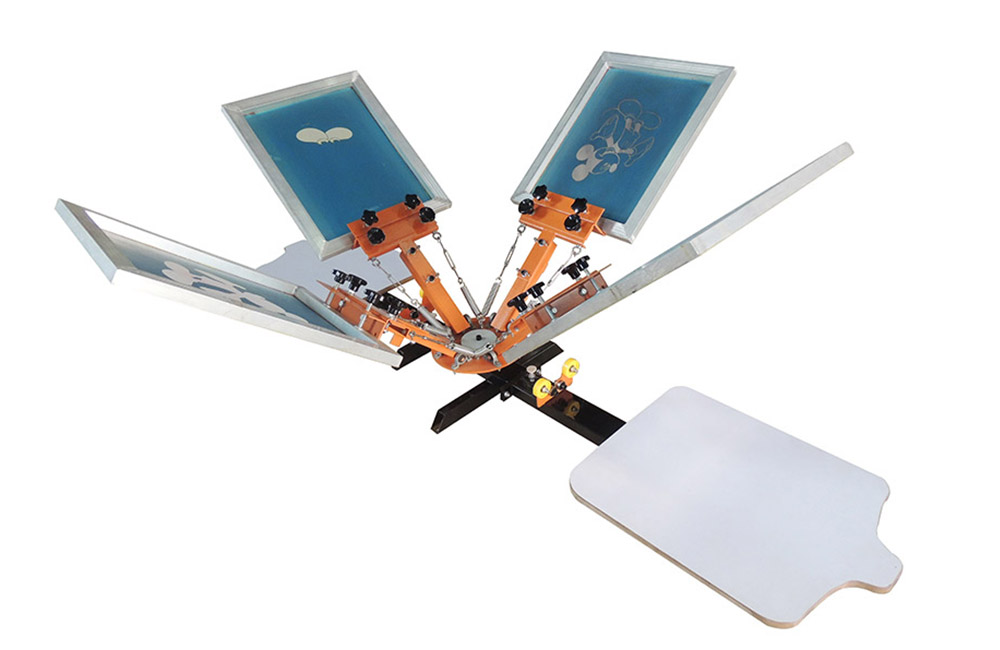

Screen printing is a popular method of transferring designs onto various surfaces, such as fabric, paper, and plastic. One crucial factor that can significantly impact the quality of screen printing results is the size of the platen. The platen is the flat surface on which the substrate (the material being printed on) is placed during the printing process. Understanding the importance of platen size and how it affects screen printing results is essential for achieving optimal outcomes.

The size of the platen directly affects the size of the design that can be printed on a substrate. A larger platen allows for larger designs to be printed, while a smaller platen limits the size of the design that can be accommodated. When selecting a platen size for a screen printing project, it is crucial to consider the size of the designs that will be printed and choose a platen that can comfortably accommodate them.

In addition to determining the size of the design that can be printed, the platen size also affects the placement of the substrate during the printing process. A larger platen provides more space for positioning the substrate, which can be particularly important when printing on larger or irregularly shaped substrates. Proper placement of the substrate is essential for achieving accurate and consistent results in screen printing.

Another important consideration when it comes to platen size is the type of printing press being used. Different types of printing presses have different platen sizes, and it is essential to select a platen size that is compatible with the specific press being used. Using a platen that is too large or too small for the press can result in poor print quality and may even damage the press.

In addition to the size of the platen, the material of the platen can also impact screen printing results. Platen materials vary in terms of durability, heat resistance, and smoothness, all of which can affect the quality of the prints. It is essential to select a platen material that is suitable for the specific printing project and that will provide the best results.

When choosing a platen size for a screen printing project, it is important to consider the specific requirements of the project, including the size of the designs, the type of substrate being printed on, and the type of printing press being used. By selecting the right platen size, you can ensure that your screen printing results are accurate, consistent, and of the highest quality.

In conclusion, understanding the importance of platen size in screen printing is essential for achieving optimal results. The size of the platen directly impacts the size of the designs that can be printed, as well as the placement of the substrate during the printing process. Selecting the right platen size for a screen printing project is crucial for ensuring accurate, consistent, and high-quality results. By considering the specific requirements of the project and choosing a platen size that is compatible with the printing press being used, you can achieve the best possible outcomes in screen printing.

Pre: Top Features to Look for in a 4 Color 2 Station Screen Printing Machine

Next: How to Print High-Quality Graphics with a 4 Color Silk Screen Press

Tags: