Troubleshooting Common Screen Printing Issues with Multi-Color Presses

Identifying and Resolving Registration Problems in Multi-Color Screen Printing

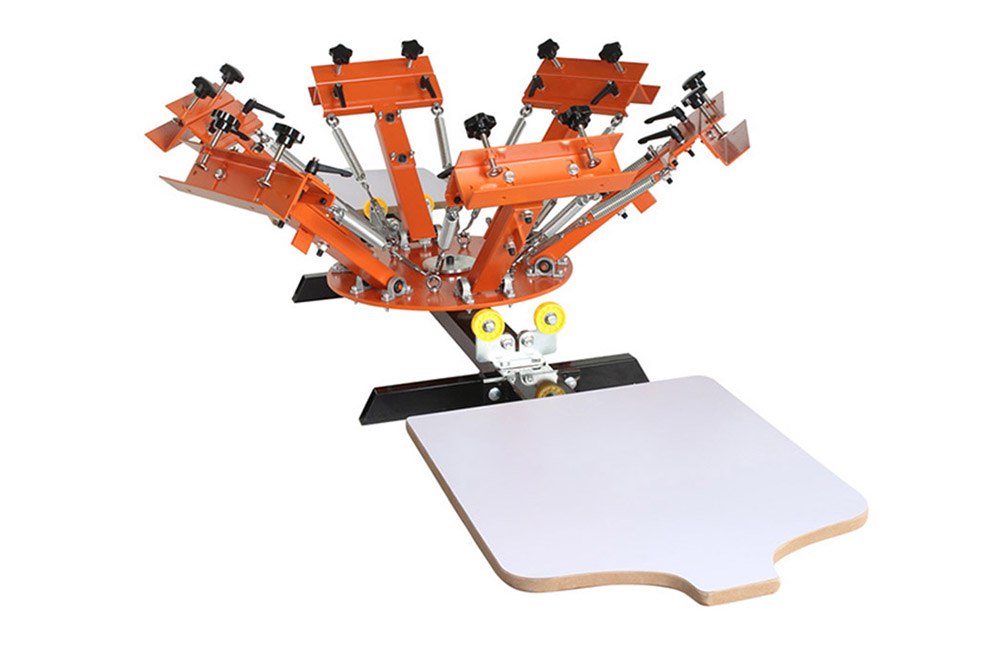

Screen printing is a popular method used to transfer images onto various surfaces, such as fabric, paper, and plastic. It is a versatile technique that allows for the creation of vibrant and detailed designs. However, like any printing process, screen printing can encounter issues that affect the quality and accuracy of the final product. One common problem that arises when using multi-color presses is registration issues.

Registration refers to the alignment of different colors in a design. In multi-color screen printing, each color is applied separately using a different screen. The screens must be aligned perfectly to ensure that the colors line up correctly and create a cohesive image. When registration is off, the design can appear blurry, misaligned, or distorted.

There are several factors that can contribute to registration problems in multi-color screen printing. One common cause is improper screen tension. If the screens are not stretched tightly enough, they can shift during the printing process, resulting in misalignment. It is important to regularly check and adjust the tension of the screens to ensure they are secure and stable.

Another factor that can affect registration is the use of incorrect or inconsistent squeegee pressure. The squeegee is used to push the ink through the screen and onto the substrate. If the pressure is too high or too low, it can cause the screens to shift and result in misalignment. It is crucial to find the right balance of pressure to achieve consistent and accurate registration.

Additionally, the type of substrate being printed on can also impact registration. Different materials have different levels of flexibility and stretch, which can affect how the ink is applied and how the colors align. It is important to test different substrates and adjust the printing process accordingly to achieve optimal registration.

To troubleshoot registration issues in multi-color screen printing, there are several steps that can be taken. First, it is important to ensure that all screens are properly aligned and secured in the press. This can be done by using registration marks or guides on the screens and substrate. These marks act as reference points to ensure that the screens are aligned correctly.

Next, it is important to check the tension of the screens and adjust as necessary. This can be done using a tension meter to measure the tension of the screens. If the tension is too loose, it can be tightened using a screen stretching tool. If the tension is too tight, it can be loosened by releasing the tension bolts.

Another step to troubleshoot registration issues is to experiment with different squeegee pressures. This can be done by adjusting the angle and pressure of the squeegee during the printing process. It may be necessary to test different pressures and angles to find the optimal settings for achieving accurate registration.

Finally, it is important to consider the substrate being printed on and make any necessary adjustments to the printing process. This can include adjusting the squeegee pressure, ink viscosity, or drying time to accommodate the specific characteristics of the substrate.

In conclusion, registration problems are a common issue when using multi-color presses in screen printing. However, by identifying the causes of these issues and taking the necessary troubleshooting steps, it is possible to achieve accurate and consistent registration. Proper screen tension, squeegee pressure, and substrate considerations are key factors in resolving registration problems and ensuring high-quality prints.

Pre: How to Avoid Fading and Cracking in Screen Printed Designs

Next: Best Budget-Friendly Screen Printing Equipment for Small Businesses

Tags: