Troubleshooting Common Issues with Vevor 4 Color 1 Station Machine

How to Fix Alignment Issues with Vevor 4 Color 1 Station Machine

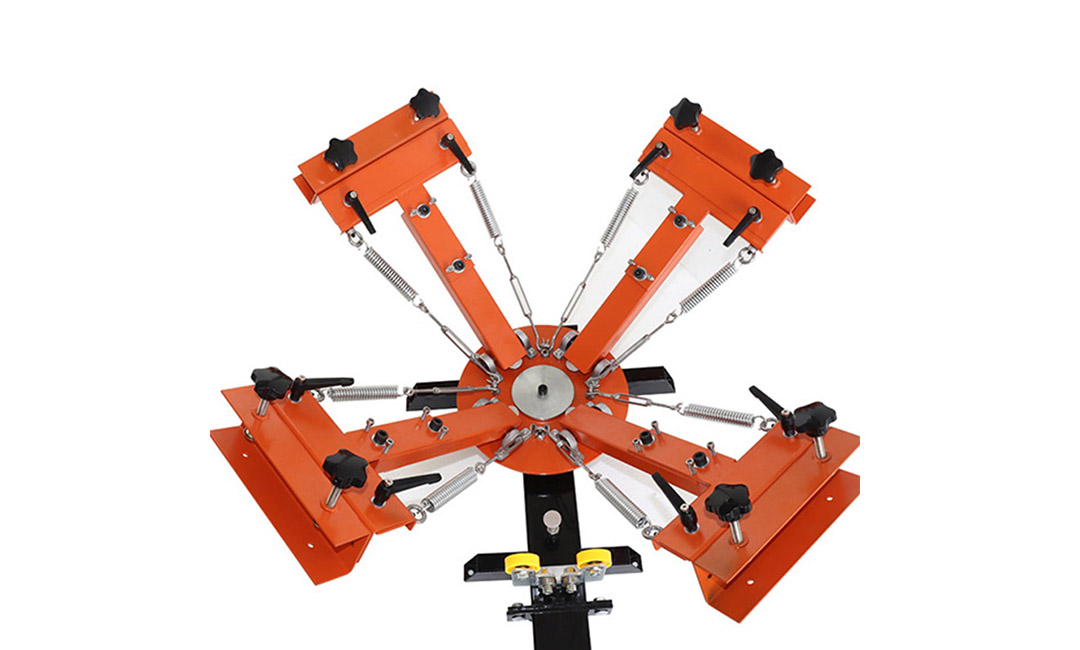

The Vevor 4 Color 1 Station Machine is a popular choice for screen printing enthusiasts looking to create high-quality prints from the comfort of their own home. However, like any piece of equipment, it can sometimes encounter issues that may affect the quality of the prints it produces. One common issue that users may face with the Vevor 4 Color 1 Station Machine is alignment problems.

Alignment issues can manifest in a variety of ways, from prints that are off-center or crooked to designs that are not properly aligned with the garment. These issues can be frustrating for users who are looking to create professional-looking prints, but fortunately, there are some steps that can be taken to troubleshoot and resolve alignment problems with the Vevor 4 Color 1 Station Machine.

One of the first things to check when experiencing alignment issues with the Vevor 4 Color 1 Station Machine is the placement of the screen on the machine. The screen should be securely fastened in place and aligned properly with the platen to ensure that the design is printed in the correct location on the garment. If the screen is not properly aligned, it can cause the design to be off-center or crooked.

To adjust the alignment of the screen on the Vevor 4 Color 1 Station Machine, users can loosen the bolts that hold the screen in place and make small adjustments to ensure that it is centered on the platen. Once the screen is properly aligned, users can tighten the bolts to secure it in place and test print to see if the alignment issue has been resolved.

Another common cause of alignment issues with the Vevor 4 Color 1 Station Machine is improper placement of the garment on the platen. If the garment is not positioned correctly, it can cause the design to be printed in the wrong location or at an angle. To ensure proper alignment, users should make sure that the garment is flat and centered on the platen before printing.

In addition to checking the placement of the screen and garment, users should also pay attention to the registration marks on the screen. Registration marks are used to align multiple colors in a design and ensure that they are printed in the correct location on the garment. If the registration marks are not properly aligned, it can cause the colors in the design to be misaligned.

To fix alignment issues caused by misaligned registration marks, users can adjust the position of the screen on the machine to ensure that the marks line up correctly. Once the registration marks are properly aligned, users can test print to see if the alignment issue has been resolved.

In conclusion, alignment issues with the Vevor 4 Color 1 Station Machine can be frustrating, but with some troubleshooting and adjustments, they can be easily resolved. By checking the placement of the screen and garment, adjusting the alignment of the screen, and ensuring that the registration marks are properly aligned, users can create professional-looking prints with their Vevor 4 Color 1 Station Machine.

Troubleshooting Ink Flow Problems on Vevor 4 Color 1 Station Machine

When it comes to screen printing, having a reliable and efficient machine is crucial for producing high-quality prints. The Vevor 4 Color 1 Station Machine is a popular choice among screen printers for its ease of use and versatility. However, like any machine, it can encounter issues that may affect its performance. One common problem that users may face with the Vevor 4 Color 1 Station Machine is ink flow issues.

Ink flow problems can be frustrating and can result in poor print quality. Fortunately, there are several troubleshooting steps that can help resolve these issues and get your machine back up and running smoothly.

One of the first things to check when experiencing ink flow problems is the viscosity of the ink. If the ink is too thick, it may not flow properly through the machine, leading to clogs and uneven prints. To remedy this, try adding a small amount of ink thinner to the ink and mix it well. This should help improve the flow of the ink and prevent clogs.

Another common cause of ink flow issues is a clogged or dirty screen. Over time, screens can become clogged with dried ink and debris, which can impede the flow of ink through the machine. To clean the screen, remove it from the machine and wash it thoroughly with a screen cleaner or a mild detergent. Be sure to rinse the screen well and allow it to dry completely before reattaching it to the machine.

In some cases, ink flow problems may be caused by a faulty or clogged ink line. Check the ink lines for any obstructions or kinks that may be preventing the ink from flowing properly. If you find any issues, try flushing the ink lines with a cleaning solution to remove any blockages. You may also need to replace the ink lines if they are damaged or worn out.

If you have checked the viscosity of the ink, cleaned the screen, and inspected the ink lines, but are still experiencing ink flow problems, it may be time to check the squeegee. The squeegee is responsible for pushing the ink through the screen and onto the substrate, so if it is damaged or worn out, it may not be able to properly distribute the ink. Inspect the squeegee for any signs of damage or wear, and replace it if necessary.

Finally, if none of the above troubleshooting steps have resolved the ink flow issues, it may be time to contact the manufacturer or a professional technician for further assistance. They may be able to diagnose the problem and provide a solution to get your Vevor 4 Color 1 Station Machine back in working order.

In conclusion, ink flow problems can be a common issue with the Vevor 4 Color 1 Station Machine, but with some troubleshooting and maintenance, you can keep your machine running smoothly and producing high-quality prints. By checking the viscosity of the ink, cleaning the screen, inspecting the ink lines, and checking the squeegee, you can address most ink flow issues and keep your machine in top condition. If all else fails, don’t hesitate to seek professional help to get your machine back on track.

Resolving Screen Printing Issues with Vevor 4 Color 1 Station Machine

Screen printing is a popular method of transferring designs onto various surfaces, such as t-shirts, bags, and posters. The Vevor 4 Color 1 Station Machine is a commonly used screen printing machine that allows users to print multiple colors onto their desired items. However, like any piece of equipment, the Vevor machine can encounter issues that may hinder its performance. In this article, we will discuss some common problems that users may face with the Vevor 4 Color 1 Station Machine and provide troubleshooting tips to help resolve these issues.

One common issue that users may encounter with the Vevor machine is uneven printing. This can result in designs that appear blotchy or faded in certain areas. Uneven printing can be caused by a variety of factors, such as improper screen tension, incorrect squeegee pressure, or uneven ink distribution. To troubleshoot this issue, users should first check the tension of the screen and adjust it as needed. Additionally, adjusting the squeegee pressure and ensuring that the ink is evenly distributed on the screen can help to improve print quality.

Another common issue with the Vevor machine is ink bleeding. Ink bleeding occurs when the ink spreads beyond the intended design, resulting in a blurry or smudged appearance. Ink bleeding can be caused by using too much ink, improper screen alignment, or using the wrong type of ink. To troubleshoot this issue, users should first ensure that they are using the correct type of ink for their desired surface. Additionally, reducing the amount of ink used and double-checking screen alignment can help to prevent ink bleeding.

Users may also encounter issues with screen registration when using the Vevor machine. Screen registration refers to the alignment of multiple screens to ensure that the colors in a design line up correctly. Poor screen registration can result in misaligned designs and a lack of color accuracy. To troubleshoot this issue, users should carefully align the screens before printing and make adjustments as needed. Additionally, using registration marks on the screens can help to ensure accurate alignment.

One final common issue that users may face with the Vevor machine is clogged screens. Clogged screens occur when ink dries and builds up on the screen, preventing proper ink flow during printing. Clogged screens can result in uneven printing and poor print quality. To troubleshoot this issue, users should regularly clean their screens after each use to prevent ink buildup. Additionally, using a screen cleaner or degreaser can help to remove stubborn ink residue and keep screens clear for optimal printing results.

In conclusion, the Vevor 4 Color 1 Station Machine is a versatile screen printing machine that can produce high-quality prints when properly maintained and used. By being aware of common issues such as uneven printing, ink bleeding, screen registration, and clogged screens, users can troubleshoot these problems and improve their printing results. By following the troubleshooting tips provided in this article, users can ensure that their Vevor machine continues to produce professional-looking prints for years to come.

Pre: How to Maintain Your Riley Hopkins 150 1 Color 1 Station Machine

Next: Why Riley Hopkins 4 Color 1 Station Press Is Perfect for Professionals

Tags: