Top Screen Printing Equipment for Large-Scale Production

Best Screen Printing Equipment for Large-Scale Production

Screen printing is a popular method of printing that involves transferring ink onto a substrate through a mesh screen. This technique is commonly used in the production of textiles, signage, and promotional materials. For businesses looking to scale up their screen printing operations, investing in high-quality equipment is essential. In this article, we will discuss some of the top screen printing equipment options for large-scale production.

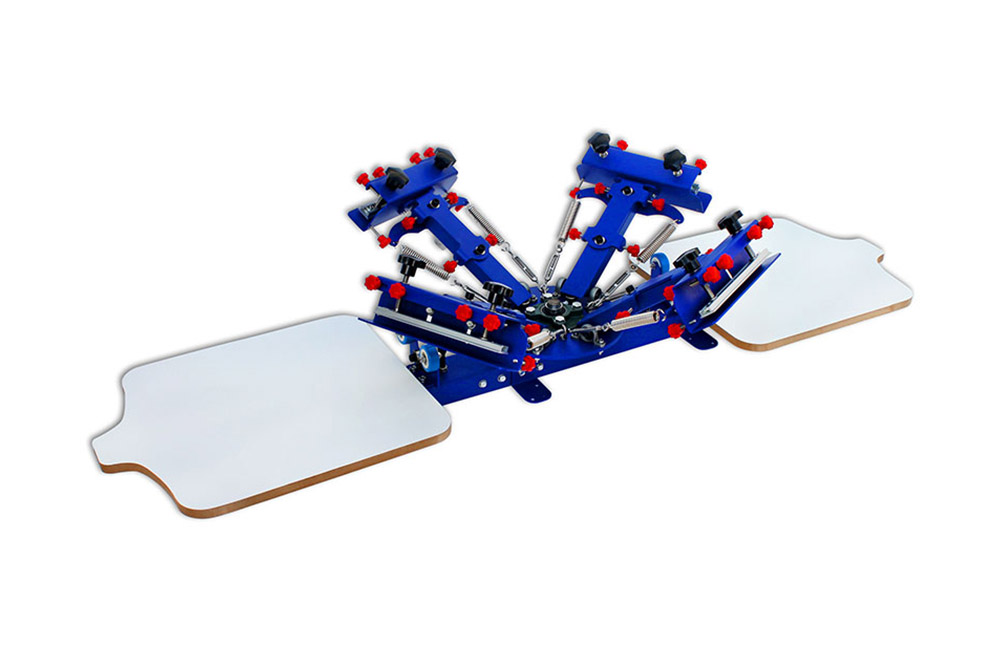

One of the key pieces of equipment needed for large-scale screen printing is an automatic screen printing press. These presses are designed to handle high volumes of prints quickly and efficiently. They are equipped with multiple print heads that can print multiple colors simultaneously, allowing for faster production times. Automatic screen printing presses also come with features such as adjustable print speeds and programmable settings, making them ideal for large-scale production runs.

Another important piece of equipment for large-scale screen printing is a conveyor dryer. Conveyor dryers are used to cure the ink on the printed substrate, ensuring that the print is durable and long-lasting. These dryers are designed to handle high volumes of prints and can be adjusted to accommodate different types of substrates. Conveyor dryers come in various sizes and configurations, making it easy to find one that suits the needs of your production facility.

In addition to automatic screen printing presses and conveyor dryers, businesses looking to scale up their screen printing operations may also benefit from investing in a flash cure unit. Flash cure units are used to partially cure the ink between color layers, allowing for faster production times and improved print quality. These units are typically mounted on the screen printing press and can be adjusted to accommodate different ink types and substrates.

When it comes to large-scale screen printing, having a reliable exposure unit is essential. Exposure units are used to create the stencils that are used in the screen printing process. These units come in various sizes and configurations, with features such as adjustable exposure times and vacuum systems for securing the screen during exposure. Investing in a high-quality exposure unit can help ensure that your prints are consistent and accurate, leading to higher customer satisfaction and repeat business.

Finally, businesses looking to scale up their screen printing operations may also want to consider investing in a screen reclaiming system. Screen reclaiming systems are used to remove the emulsion from screens after printing, allowing them to be reused for future print runs. These systems come with features such as pressure washers, emulsion removers, and drying racks, making it easy to reclaim screens quickly and efficiently. By investing in a screen reclaiming system, businesses can reduce waste and save money on screen replacement costs.

In conclusion, investing in high-quality screen printing equipment is essential for businesses looking to scale up their production operations. Automatic screen printing presses, conveyor dryers, flash cure units, exposure units, and screen reclaiming systems are all important pieces of equipment that can help businesses increase their production capacity and improve print quality. By choosing the right equipment for your needs, you can streamline your production process, reduce waste, and increase profitability in the long run.

Pre: Why Small Screen Printing Machines Are Ideal for Home Use

Next: Using a 4 Color Silk Screen Printing Machine for High-Quality Apparel

Tags: