Top Maintenance Tips for Keeping Your Screen Printing Press Running

Regular Cleaning and Lubrication

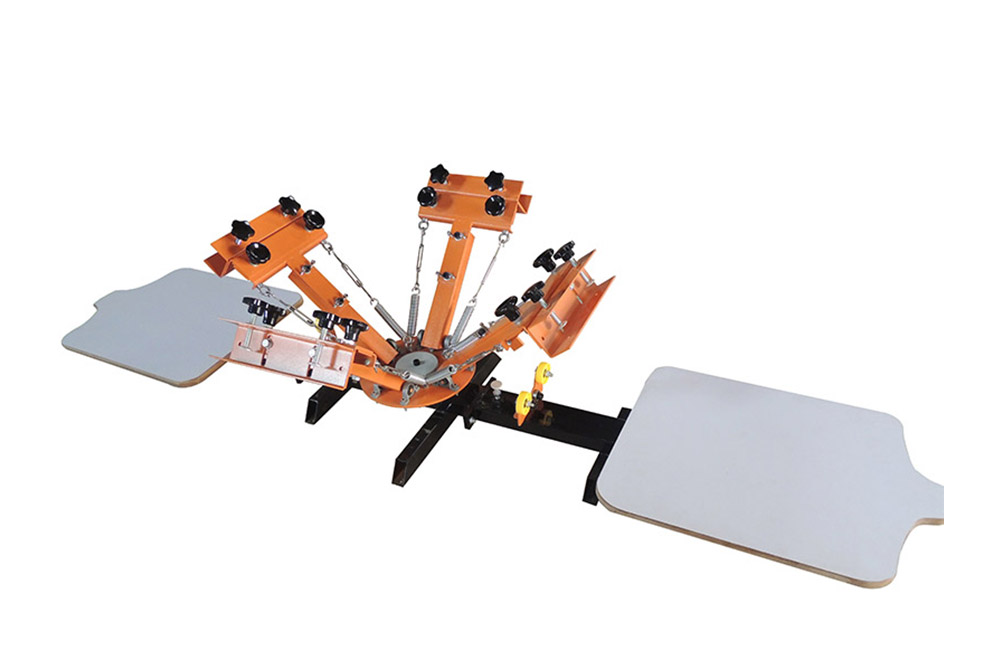

Screen printing presses are essential tools for any printing business, allowing for high-quality prints on a variety of materials. To ensure that your screen printing press continues to run smoothly and efficiently, regular maintenance is key. In this article, we will discuss some top maintenance tips for keeping your screen printing press running smoothly.

One of the most important aspects of maintaining your screen printing press is regular cleaning and lubrication. Dust, ink, and debris can build up on the press over time, leading to malfunctions and decreased print quality. To prevent this buildup, it is important to clean your press regularly. This can be done by wiping down the press with a damp cloth and using a mild detergent to remove any stubborn stains. Be sure to also clean the screens, squeegees, and other components of the press to ensure optimal performance.

In addition to cleaning, lubrication is also crucial for keeping your screen printing press running smoothly. Lubricating the moving parts of the press will help reduce friction and wear, extending the life of the machine. Be sure to use a high-quality lubricant that is compatible with the materials used in your press. Apply the lubricant to the moving parts of the press according to the manufacturer’s recommendations to ensure proper maintenance.

Regular cleaning and lubrication are essential for keeping your screen printing press running smoothly. By incorporating these maintenance tasks into your regular routine, you can prevent costly repairs and downtime, ensuring that your press continues to produce high-quality prints for years to come.

Another important maintenance tip for keeping your screen printing press running smoothly is to check for any loose or damaged parts. Over time, the components of the press can become loose or worn, leading to malfunctions and decreased performance. To prevent this, it is important to regularly inspect the press for any signs of wear or damage. Tighten any loose screws or bolts, and replace any damaged parts as needed to ensure optimal performance.

In addition to checking for loose or damaged parts, it is also important to calibrate your screen printing press regularly. Calibration ensures that the press is operating at its optimal settings, producing high-quality prints with accurate colors and registration. Follow the manufacturer’s guidelines for calibrating your press, and make any necessary adjustments to ensure that it is running smoothly.

By incorporating regular cleaning, lubrication, and maintenance checks into your routine, you can keep your screen printing press running smoothly and efficiently. These simple maintenance tasks can help prevent costly repairs and downtime, ensuring that your press continues to produce high-quality prints for years to come. Remember to follow the manufacturer’s recommendations for maintenance and care, and consult a professional if you encounter any issues with your press. With proper maintenance, your screen printing press will continue to be a valuable asset to your printing business.

Pre: Where to Find Affordable Screen Printing Presses for Sale

Next: Choosing the Best Screen Printing Press for Multi-Color Projects

Tags: