Top Maintenance Tips for a One Station Screen Printing Press

Regular Cleaning and Lubrication

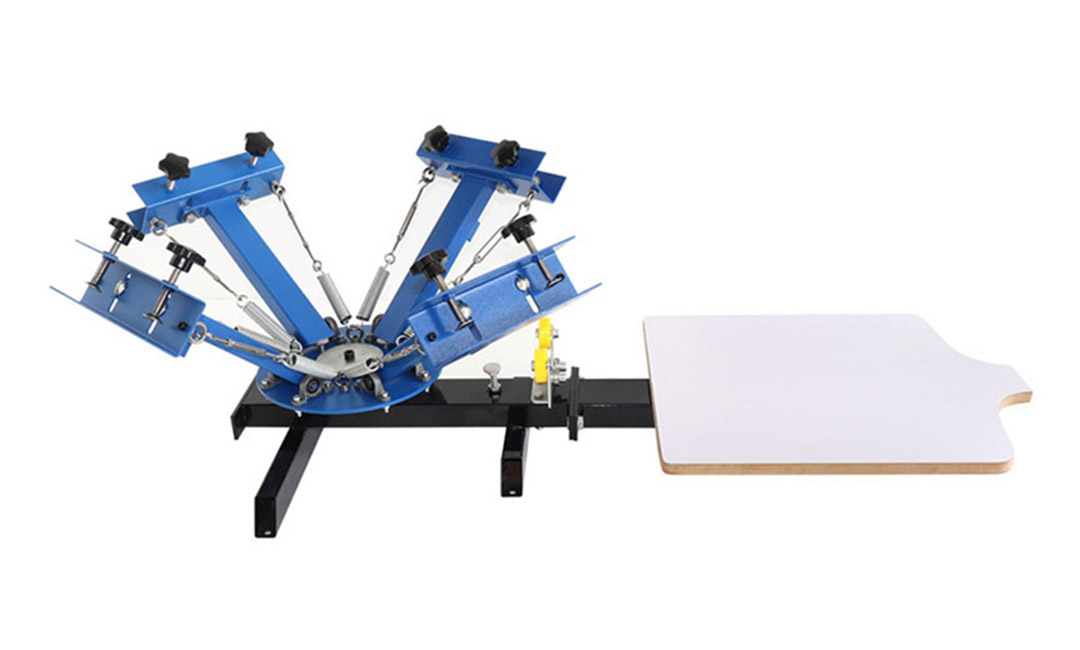

Screen printing is a popular method of printing designs onto various surfaces, such as t-shirts, posters, and more. To ensure that your one station screen printing press continues to operate smoothly and efficiently, regular maintenance is essential. In this article, we will discuss some top maintenance tips for a one station screen printing press, focusing on regular cleaning and lubrication.

One of the most important aspects of maintaining a one station screen printing press is regular cleaning. Over time, ink and debris can build up on the press, leading to poor print quality and potential damage to the machine. To prevent this, it is important to clean the press after each use. Start by wiping down the surfaces of the press with a damp cloth to remove any excess ink or debris. Pay special attention to the screen and squeegee, as these are the parts of the press that come into direct contact with the ink.

In addition to regular cleaning, lubrication is also key to keeping your one station screen printing press in top condition. Lubricating the moving parts of the press will help to reduce friction and wear, prolonging the life of the machine. Before lubricating the press, be sure to consult the manufacturer’s guidelines to determine the appropriate type of lubricant to use. Apply a small amount of lubricant to the moving parts of the press, such as the hinges and bearings, and wipe away any excess to prevent buildup.

Another important maintenance tip for a one station screen printing press is to regularly check and adjust the tension of the screen. The tension of the screen plays a crucial role in the quality of the print, so it is important to ensure that it is properly adjusted. Use a tension meter to measure the tension of the screen, and make any necessary adjustments to achieve the desired tension. This will help to ensure that your prints are crisp and clear, without any smudging or blurring.

In addition to cleaning, lubricating, and adjusting the tension of the screen, it is also important to regularly inspect the press for any signs of wear or damage. Check the hinges, bearings, and other moving parts for any signs of wear, and replace any damaged parts as needed. Keeping an eye on the condition of the press will help to prevent any major issues from arising and ensure that the press continues to operate smoothly.

By following these top maintenance tips for a one station screen printing press, you can help to prolong the life of the machine and ensure that your prints are of the highest quality. Regular cleaning and lubrication, adjusting the tension of the screen, and inspecting the press for wear and damage are all essential steps in maintaining a one station screen printing press. With proper maintenance, your press will continue to produce high-quality prints for years to come.

Pre: 4 Colour 1 Station Screen Printing Machine: Pros, Cons, and Applications

Next: Key Differences Between Riley Hopkins 150 4 Color 1 Station and Other Presses

Tags: