Tips for Effective Heat Curing to Ensure Vibrant and Durable Prints

Proper Temperature Control during Heat Curing

Heat curing is a crucial step in the printing process that ensures vibrant and durable prints. Proper temperature control during heat curing is essential to achieve the desired results. In this article, we will discuss some tips for effective heat curing to ensure vibrant and durable prints.

One of the most important factors to consider when heat curing prints is the temperature. It is essential to maintain a consistent temperature throughout the curing process to ensure that the prints are properly cured. Fluctuations in temperature can result in uneven curing, leading to poor print quality.

To achieve proper temperature control during heat curing, it is important to use a reliable heat source. A heat press or a conveyor dryer is commonly used for heat curing prints. These heat sources provide consistent and even heat distribution, ensuring that the prints are cured uniformly.

It is also important to monitor the temperature throughout the curing process. A temperature gun or a thermometer can be used to measure the temperature of the prints. It is recommended to set the temperature according to the manufacturer’s guidelines for the specific type of ink and substrate being used.

In addition to maintaining the proper temperature, it is also important to consider the curing time. Overcuring or undercuring prints can result in poor adhesion and durability. It is important to follow the recommended curing time provided by the ink manufacturer to ensure that the prints are properly cured.

Another important tip for effective heat curing is to allow the prints to cool down properly after curing. Rapid cooling can cause the prints to shrink or crack, compromising their durability. It is recommended to let the prints cool down gradually before handling or packaging them.

Proper ventilation is also important during heat curing to ensure that any fumes or gases released during the curing process are safely removed. It is recommended to use a well-ventilated area or a ventilation system to prevent exposure to harmful fumes.

In conclusion, proper temperature control during heat curing is essential to ensure vibrant and durable prints. By using a reliable heat source, monitoring the temperature, following the recommended curing time, allowing the prints to cool down properly, and ensuring proper ventilation, you can achieve high-quality prints that are vibrant and durable. Following these tips will help you achieve the best results in your printing projects.

Importance of Even Heat Distribution

Heat curing is a crucial step in the process of creating vibrant and durable prints on various substrates. Proper heat curing ensures that the ink is fully cured, resulting in prints that are resistant to fading, cracking, and peeling. One of the key factors that contribute to successful heat curing is the even distribution of heat across the entire surface of the print.

Uneven heat distribution can lead to inconsistent curing, which can result in prints that are not as vibrant or durable as desired. To ensure that heat is evenly distributed during the curing process, it is important to use a heat press or oven that is properly calibrated and maintained. Additionally, using a heat press or oven with a large enough surface area to accommodate the entire print can help to ensure that heat is evenly distributed.

Another important factor to consider when heat curing prints is the type of substrate being used. Different substrates require different curing temperatures and times, so it is important to follow the manufacturer’s recommendations for the specific substrate being used. Additionally, using a heat press or oven with adjustable temperature and time settings can help to ensure that the curing process is tailored to the specific requirements of the substrate.

Proper ventilation is also important when heat curing prints, as the curing process can release fumes that may be harmful if inhaled. Ensuring that the curing area is well-ventilated can help to protect the health and safety of those involved in the curing process.

In addition to ensuring even heat distribution, it is important to monitor the curing process to ensure that the prints are being cured properly. This can be done by using a temperature gun to measure the temperature of the print surface during the curing process. Monitoring the temperature of the print surface can help to ensure that the prints are being cured at the correct temperature for the correct amount of time.

It is also important to allow the prints to cool properly after the curing process is complete. Allowing the prints to cool slowly can help to prevent them from becoming distorted or damaged. Placing the prints on a flat surface to cool can help to ensure that they retain their shape and vibrancy.

In conclusion, ensuring even heat distribution during the heat curing process is essential for creating vibrant and durable prints. Using a properly calibrated and maintained heat press or oven, following the manufacturer’s recommendations for curing temperatures and times, and monitoring the curing process can help to ensure that prints are cured properly. Proper ventilation and allowing prints to cool properly after curing are also important factors to consider when heat curing prints. By following these tips for effective heat curing, you can create prints that are vibrant, durable, and long-lasting.

Choosing the Right Heat Curing Equipment

Heat curing is a crucial step in the printing process that ensures vibrant and durable prints. By properly curing the ink, you can achieve long-lasting results that will withstand wear and tear. However, in order to achieve the best results, it is important to choose the right heat curing equipment for your specific needs.

When selecting heat curing equipment, there are several factors to consider. The first thing to think about is the size of your prints. If you are working with large prints, you will need a heat curing unit that can accommodate the size of your prints. Additionally, you will want to consider the type of ink you are using, as different inks require different curing temperatures and times.

Another important factor to consider when choosing heat curing equipment is the type of substrate you are printing on. Some substrates, such as textiles, require lower curing temperatures, while others, such as metal or glass, may require higher temperatures. It is important to choose a heat curing unit that can reach the necessary temperature for your specific substrate.

In addition to considering the size of your prints and the type of substrate you are working with, it is also important to think about the speed at which you need to cure your prints. Some heat curing units offer faster curing times than others, which can be beneficial if you have a high volume of prints to process.

Once you have considered these factors, it is time to choose the right heat curing equipment for your needs. There are several different types of heat curing units available, including conveyor dryers, flash dryers, and heat presses. Each type of equipment has its own advantages and disadvantages, so it is important to choose the one that best suits your specific requirements.

Conveyor dryers are a popular choice for heat curing large volumes of prints. These units use a conveyor belt to move prints through a heated chamber, ensuring even curing across the entire print. Conveyor dryers are ideal for high-volume production runs and can be customized to meet your specific needs.

Flash dryers are another option for heat curing prints. These units use infrared heat to quickly cure prints, making them ideal for smaller production runs or for spot curing specific areas of a print. Flash dryers are compact and easy to use, making them a popular choice for smaller print shops.

Heat presses are another type of heat curing equipment that are commonly used for curing prints on textiles. These units use a combination of heat and pressure to cure prints, ensuring a durable and vibrant result. Heat presses are ideal for printing on fabrics and can be used for both small and large production runs.

In conclusion, choosing the right heat curing equipment is essential for achieving vibrant and durable prints. By considering factors such as print size, substrate type, curing speed, and production volume, you can select the equipment that best suits your specific needs. Whether you choose a conveyor dryer, flash dryer, or heat press, investing in quality heat curing equipment will ensure that your prints look their best and stand the test of time.

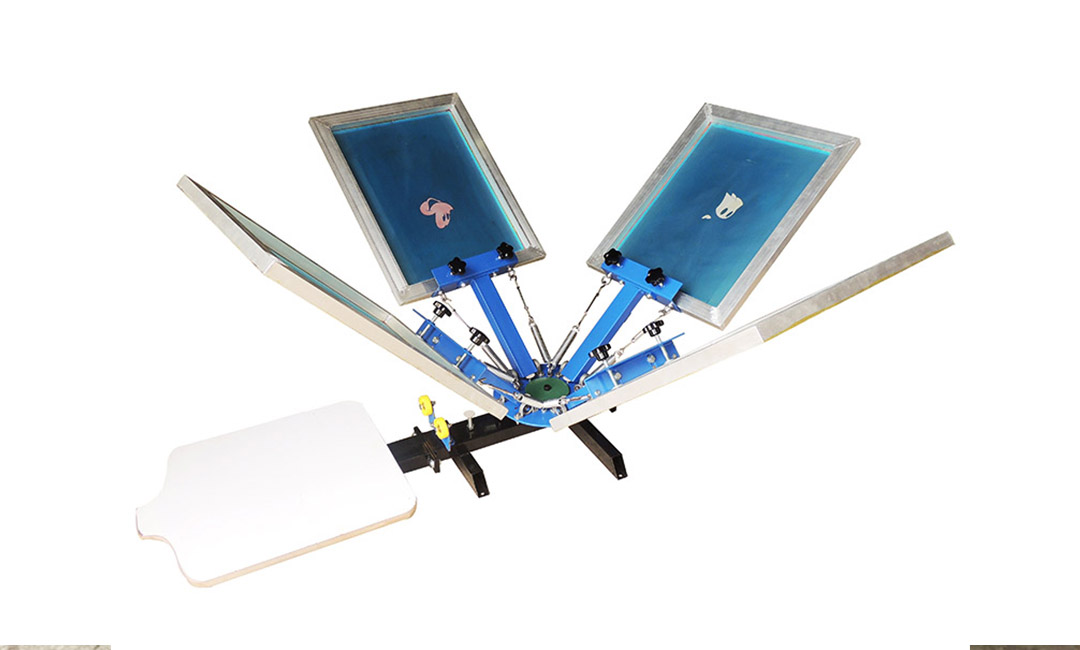

Pre: What to Know About 4 Color Screen Printers for Custom Apparel

Next: Tips for Perfecting Screen Printing Techniques for T-Shirts

Tags: