The Key Differences Between Direct-to-Garment and Screen Printing for Custom Apparel

Pros and Cons of Direct-to-Garment Printing

When it comes to creating custom apparel, there are several printing methods to choose from. Two popular options are direct-to-garment (DTG) printing and screen printing. Each method has its own set of pros and cons, which can make it difficult to decide which one is best for your project. In this article, we will explore the key differences between DTG and screen printing, focusing on the pros and cons of DTG printing.

One of the main advantages of DTG printing is its ability to produce high-quality, detailed prints. DTG printers use specialized inkjet technology to apply ink directly onto the fabric, resulting in vibrant colors and intricate designs. This makes DTG printing ideal for projects that require a high level of detail, such as photographs or complex graphics.

Another benefit of DTG printing is its versatility. DTG printers can print on a wide range of fabrics, including cotton, polyester, and blends. This makes DTG printing a great option for creating custom apparel for a variety of purposes, from promotional items to personalized gifts.

In addition to its high-quality prints and versatility, DTG printing is also a cost-effective option for small batch orders. Unlike screen printing, which requires the creation of screens for each color in the design, DTG printing does not have any setup costs. This makes DTG printing a great choice for projects with multiple colors or designs, as there is no additional cost for each color.

Despite its many advantages, DTG printing does have some drawbacks. One of the main disadvantages of DTG printing is its limited color range. DTG printers use CMYK ink, which can result in color variations when printing certain shades. This can be a problem for projects that require precise color matching, such as corporate branding or team uniforms.

Another potential downside of DTG printing is its durability. While DTG prints are generally washable, they may not hold up as well as screen prints over time. This is especially true for prints on dark-colored fabrics, which can fade or crack after multiple washes. For projects that require long-lasting prints, screen printing may be a better option.

In conclusion, DTG printing offers a number of benefits, including high-quality prints, versatility, and cost-effectiveness for small batch orders. However, it also has some limitations, such as a limited color range and potential durability issues. When deciding between DTG and screen printing for your custom apparel project, it is important to consider the specific requirements of your design and budget. By weighing the pros and cons of each method, you can choose the printing option that best suits your needs.

Benefits and Limitations of Screen Printing

Screen printing and direct-to-garment (DTG) printing are two popular methods for creating custom apparel. Each method has its own set of benefits and limitations that make them suitable for different types of projects. In this article, we will explore the key differences between screen printing and DTG printing, focusing on the benefits and limitations of screen printing.

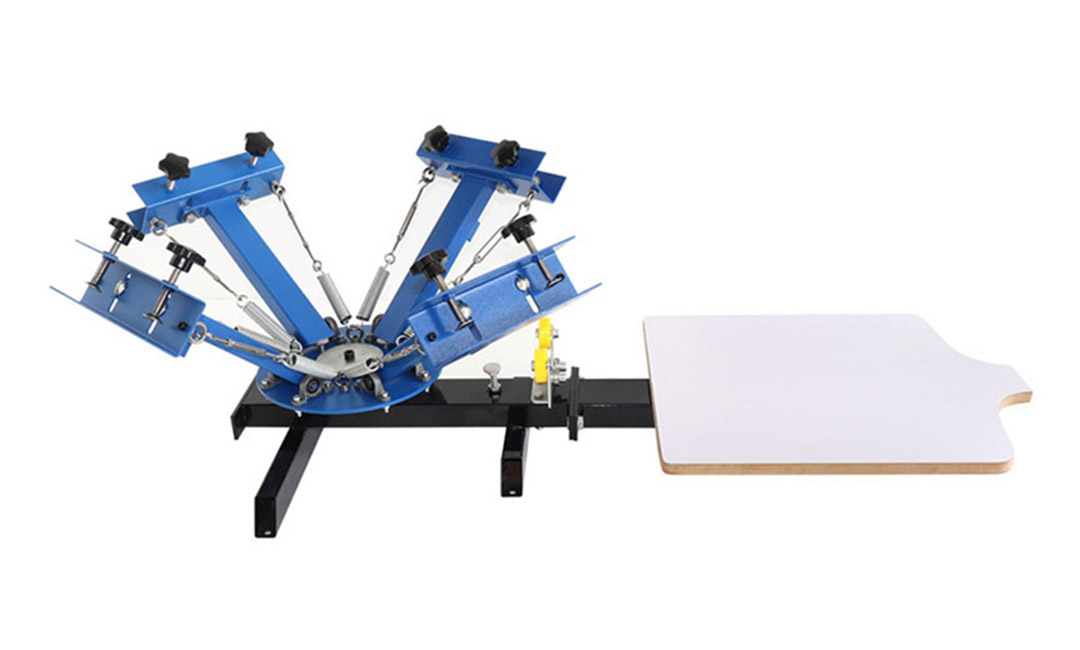

Screen printing is a traditional method of printing that involves creating a stencil, or screen, for each color in the design. Ink is then pushed through the screen onto the fabric, creating a vibrant and durable print. One of the main benefits of screen printing is its versatility. Screen printing can be used on a wide range of fabrics, including cotton, polyester, and blends. This makes it a popular choice for creating custom apparel such as t-shirts, hoodies, and tote bags.

Another benefit of screen printing is its ability to create bold and vibrant prints. Because screen printing uses thick layers of ink, colors appear more saturated and opaque compared to other printing methods. This makes screen printing ideal for designs with solid colors or intricate details. Additionally, screen printing is a cost-effective option for large orders. Once the screens are created, the printing process is relatively quick and efficient, making it a cost-effective option for bulk orders.

However, screen printing also has its limitations. One of the main limitations of screen printing is the complexity of the setup process. Creating screens for each color in the design can be time-consuming and labor-intensive, especially for designs with multiple colors. Additionally, screen printing is not ideal for designs with gradients or fine details. Because screen printing uses solid layers of ink, it can be difficult to achieve smooth transitions between colors or intricate details.

Another limitation of screen printing is its environmental impact. Screen printing requires the use of chemicals and solvents to create and clean the screens, which can be harmful to the environment if not disposed of properly. Additionally, screen printing is not a sustainable option for small orders. Because of the setup process involved, screen printing is more cost-effective for larger orders, making it less suitable for small businesses or individuals looking to create custom apparel in small quantities.

In conclusion, screen printing is a versatile and cost-effective option for creating custom apparel. Its ability to create bold and vibrant prints on a wide range of fabrics makes it a popular choice for large orders. However, the complexity of the setup process and limitations on design details make screen printing less suitable for small orders or designs with gradients or fine details. Understanding the benefits and limitations of screen printing can help you make an informed decision when choosing a printing method for your custom apparel project.

Cost Comparison Between Direct-to-Garment and Screen Printing

When it comes to creating custom apparel, there are several printing methods to choose from. Two popular options are direct-to-garment (DTG) printing and screen printing. Both methods have their own unique advantages and disadvantages, and understanding the key differences between the two can help you make an informed decision when it comes to creating your custom apparel.

One of the most significant factors to consider when choosing between DTG and screen printing is the cost. DTG printing is typically more expensive than screen printing, especially for larger orders. This is because DTG printing requires specialized equipment and ink, which can be costly to maintain. In contrast, screen printing is a more traditional and cost-effective method that has been used for decades.

Another cost consideration is the setup fees associated with each printing method. Screen printing requires the creation of screens for each color in the design, which can add to the overall cost of the project. DTG printing, on the other hand, does not require screens, making it a more cost-effective option for designs with multiple colors.

In addition to setup fees, the cost per print is also an important factor to consider. DTG printing tends to have a higher cost per print compared to screen printing, especially for larger orders. This is because DTG printing uses more ink and takes longer to complete each print. Screen printing, on the other hand, is a faster and more efficient process, making it a more cost-effective option for larger orders.

It’s important to note that the cost of custom apparel can vary depending on the complexity of the design, the number of colors used, and the size of the order. For simple designs with fewer colors, screen printing may be the more cost-effective option. However, for designs with intricate details and multiple colors, DTG printing may be the better choice.

Ultimately, the cost of custom apparel will depend on your specific needs and budget. It’s important to consider all factors, including setup fees, cost per print, and the complexity of the design, when choosing between DTG and screen printing.

In conclusion, there are several key differences between DTG and screen printing when it comes to creating custom apparel. While DTG printing may be more expensive than screen printing, it offers a high level of detail and color accuracy that is difficult to achieve with traditional screen printing methods. On the other hand, screen printing is a cost-effective option for larger orders and simple designs.

When deciding between DTG and screen printing, it’s important to consider your specific needs and budget. By understanding the key differences between the two methods, you can make an informed decision that will result in high-quality custom apparel that meets your needs and exceeds your expectations.

Pre: Tips for Perfecting Screen Printing Techniques for T-Shirts

Next: How to Choose a Budget-Friendly Press for Shirt Printing

Tags: