Step-by-Step Setup Guide for Vevor 4 Color 1 Station Screen Printing Machine

Proper Assembly of the Vevor 4 Color 1 Station Screen Printing Machine

Screen printing is a popular method for creating high-quality prints on various surfaces, from t-shirts to posters. If you’re looking to get started with screen printing, the Vevor 4 Color 1 Station Screen Printing Machine is a great option for beginners. In this article, we will provide a step-by-step setup guide to help you properly assemble your Vevor screen printing machine.

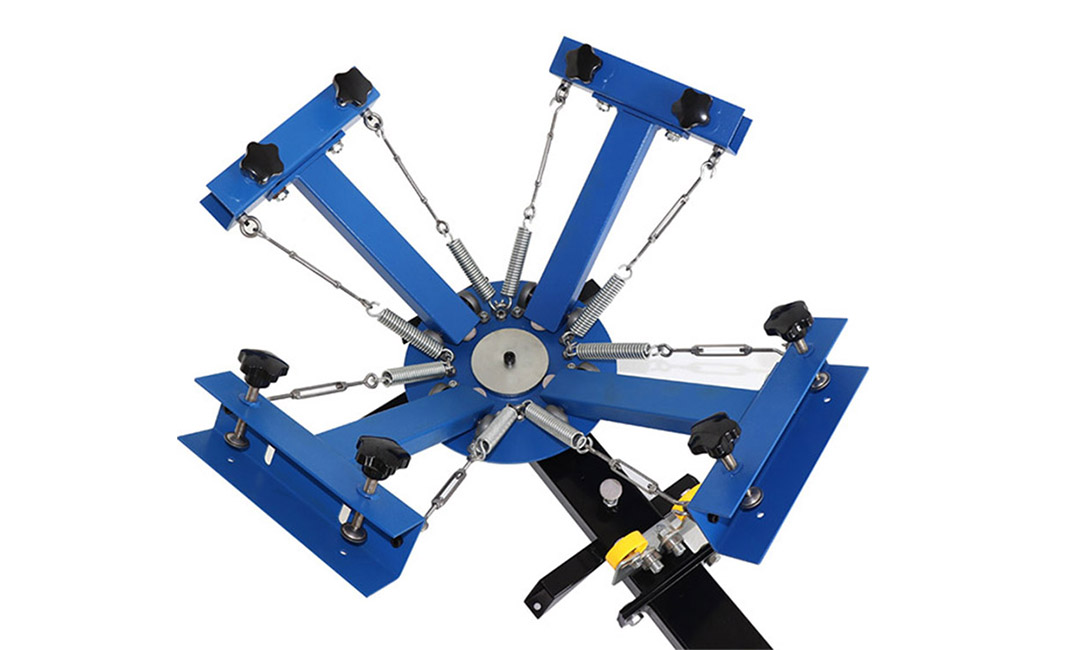

The first step in setting up your Vevor screen printing machine is to unpack all the components and lay them out in an organized manner. Make sure you have all the necessary parts, including the base, arms, screens, squeegees, and ink. Once you have everything laid out, you can begin assembling the machine.

Start by attaching the arms to the base of the machine. The arms should slide easily into the designated slots on the base. Make sure they are securely in place before moving on to the next step. Next, attach the screens to the arms. The screens should fit snugly onto the arms and be securely fastened in place.

Once the screens are attached, it’s time to install the squeegees. The squeegees are used to push the ink through the screen onto the printing surface. Make sure the squeegees are properly aligned with the screens and are securely attached to the arms.

After the squeegees are in place, you can set up the ink. Place the ink in the designated slots on the machine, making sure it is easily accessible for printing. You may need to adjust the height of the screens and squeegees to ensure proper alignment with the printing surface.

Once everything is set up, you can test the machine by running a test print. Load the ink onto the screen, place the printing surface underneath, and use the squeegee to push the ink through the screen. If the print comes out clean and clear, your machine is properly set up and ready for use.

In conclusion, setting up the Vevor 4 Color 1 Station Screen Printing Machine is a straightforward process that can be completed in just a few simple steps. By following this step-by-step guide, you can ensure that your machine is properly assembled and ready for use. Screen printing can be a fun and rewarding hobby, and with the Vevor screen printing machine, you can create professional-quality prints right in your own home. So don’t wait any longer – get your Vevor screen printing machine set up today and start creating your own custom prints!

Adjusting and Calibrating the Machine for Optimal Printing Results

Screen printing is a popular method for creating high-quality prints on various surfaces, from t-shirts to posters. If you’re looking to get started with screen printing, the Vevor 4 Color 1 Station Screen Printing Machine is a great option for beginners. In this article, we will provide a step-by-step setup guide for this machine, focusing on adjusting and calibrating it for optimal printing results.

Before you begin setting up the Vevor screen printing machine, make sure you have all the necessary tools and materials on hand. This includes ink, screens, squeegees, and the printing machine itself. Once you have everything you need, follow these steps to adjust and calibrate the machine for optimal printing results.

First, start by assembling the machine according to the manufacturer’s instructions. Make sure all the parts are securely attached and that the machine is stable. Once the machine is assembled, adjust the height of the screen frame to ensure it is level with the printing platen. This will help prevent smudging and ensure even ink distribution.

Next, adjust the off-contact distance between the screen and the printing platen. The off-contact distance refers to the space between the screen and the substrate being printed on. This distance should be around 1/8 inch to 1/4 inch for optimal printing results. Adjust the off-contact distance by loosening the knobs on the screen frame and raising or lowering it as needed.

After adjusting the off-contact distance, calibrate the screen tension to ensure a smooth and even print. Proper screen tension is essential for achieving crisp and clear prints. Use a tension meter to measure the tension of the screen and adjust it as needed by tightening or loosening the bolts on the screen frame.

Once the screen tension is calibrated, it’s time to set up the registration marks on the screen. Registration marks are used to align the different colors in a multi-color print. Use a registration template to mark the registration points on the screen and the printing platen. This will help ensure that each color is printed in the correct position.

After setting up the registration marks, it’s time to prepare the ink for printing. Make sure the ink is properly mixed and free of any clumps or impurities. Load the ink onto the screen using a squeegee, making sure to apply even pressure to ensure an even coat of ink on the screen.

Finally, test print a few samples to check the quality of the print and make any necessary adjustments. Pay attention to factors such as ink coverage, registration, and overall print quality. Make any adjustments as needed to achieve the desired results.

In conclusion, setting up the Vevor 4 Color 1 Station Screen Printing Machine for optimal printing results requires careful adjustment and calibration. By following the steps outlined in this guide, you can ensure that your prints are crisp, clear, and professional-looking. With practice and patience, you’ll be able to create high-quality prints with ease using this versatile screen printing machine.

Troubleshooting Common Issues with the Vevor 4 Color 1 Station Screen Printing Machine

Screen printing is a popular method for creating high-quality prints on various surfaces, from t-shirts to posters. The Vevor 4 Color 1 Station Screen Printing Machine is a reliable and efficient tool for screen printing enthusiasts and professionals alike. However, like any piece of equipment, it may encounter some common issues that can be easily resolved with the right troubleshooting steps.

One common issue that users may encounter with the Vevor 4 Color 1 Station Screen Printing Machine is uneven ink coverage. This can result in prints that appear blotchy or faded in certain areas. To troubleshoot this issue, start by checking the screen tension. A loose screen can cause the ink to spread unevenly, resulting in poor print quality. Make sure the screen is securely fastened to the frame and adjust the tension as needed.

Another possible cause of uneven ink coverage is improper squeegee pressure. If the squeegee is pressing too lightly or too heavily on the screen, it can cause the ink to be distributed unevenly. Adjust the squeegee pressure to ensure that it is applying consistent pressure across the entire surface of the screen.

In some cases, uneven ink coverage may be caused by a clogged or damaged screen. Inspect the screen for any debris or damage, and clean or replace it if necessary. Additionally, make sure that the screen is properly aligned with the substrate to ensure that the ink is applied evenly.

Another common issue that users may encounter with the Vevor 4 Color 1 Station Screen Printing Machine is ghosting. Ghosting occurs when a faint image or design from a previous print appears on a subsequent print. This can be caused by improper curing of the ink, insufficient cleaning of the screen, or improper alignment of the screen and substrate.

To troubleshoot ghosting, start by ensuring that the ink is properly cured. Follow the manufacturer’s instructions for curing the ink, and make sure that the print is fully dry before moving on to the next step. If ghosting persists, try cleaning the screen with a screen cleaner to remove any residual ink or debris that may be causing the issue.

Improper alignment of the screen and substrate can also cause ghosting. Make sure that the screen is properly aligned with the substrate before printing to prevent any overlap between prints. Adjust the screen as needed to ensure that it is aligned correctly.

By following these troubleshooting steps, users can address common issues with the Vevor 4 Color 1 Station Screen Printing Machine and achieve high-quality prints with ease. With proper maintenance and attention to detail, this screen printing machine can continue to produce professional results for years to come.

Pre: How to Get Started with a One Station Screen Printing Press at Home

Tags: