Step-by-Step Installation of Riley Hopkins 150 4 Color 1 Station

Required Tools for Installing Riley Hopkins 150 4 Color 1 Station

When it comes to setting up a Riley Hopkins 150 4 Color 1 Station press, having the right tools on hand is essential. This article will guide you through the step-by-step installation process, starting with the tools you will need to ensure a smooth and successful setup.

First and foremost, you will need a set of basic hand tools, including a Phillips head screwdriver, a flat head screwdriver, and an adjustable wrench. These tools will be used to assemble the various components of the press, such as the print head, pallet arms, and base.

In addition to hand tools, you will also need a level to ensure that the press is set up on a flat and even surface. This will help to prevent any issues with alignment and ensure that your prints come out clean and crisp.

Another important tool to have on hand is a tape measure. This will be used to measure and adjust the distance between the print head and the pallet, as well as the distance between the pallet and the base of the press. Accurate measurements are crucial for achieving precise prints, so be sure to take your time with this step.

Lastly, you will need a set of Allen wrenches to tighten the various bolts and screws on the press. These wrenches come in various sizes, so be sure to have a set that includes all the sizes needed for the installation of the Riley Hopkins 150 4 Color 1 Station press.

With all of your tools gathered and ready to go, you can now begin the installation process. Start by unpacking the press and laying out all of the components in an organized manner. This will make it easier to identify and assemble each part as you go along.

Next, follow the manufacturer’s instructions to assemble the print head, pallet arms, and base of the press. Use your hand tools to tighten all of the bolts and screws securely, making sure that everything is aligned properly.

Once the press is fully assembled, use your level to ensure that it is sitting on a flat surface. Adjust the feet of the press as needed to achieve a level position, taking care to check the alignment of the print head and pallet arms as you go.

With the press level and properly aligned, use your tape measure to adjust the distance between the print head and the pallet. This distance will vary depending on the size of the prints you are planning to produce, so be sure to refer to the manufacturer’s guidelines for the correct measurements.

Finally, tighten all of the bolts and screws on the press using your Allen wrenches, making sure that everything is secure and stable. Once you have completed these steps, your Riley Hopkins 150 4 Color 1 Station press should be ready to use.

In conclusion, having the right tools on hand is essential for a successful installation of the Riley Hopkins 150 4 Color 1 Station press. By following the step-by-step guide outlined in this article and taking your time to ensure that everything is properly assembled and aligned, you can set up your press with confidence and start producing high-quality prints in no time.

Step-by-Step Guide to Assembling Riley Hopkins 150 4 Color 1 Station

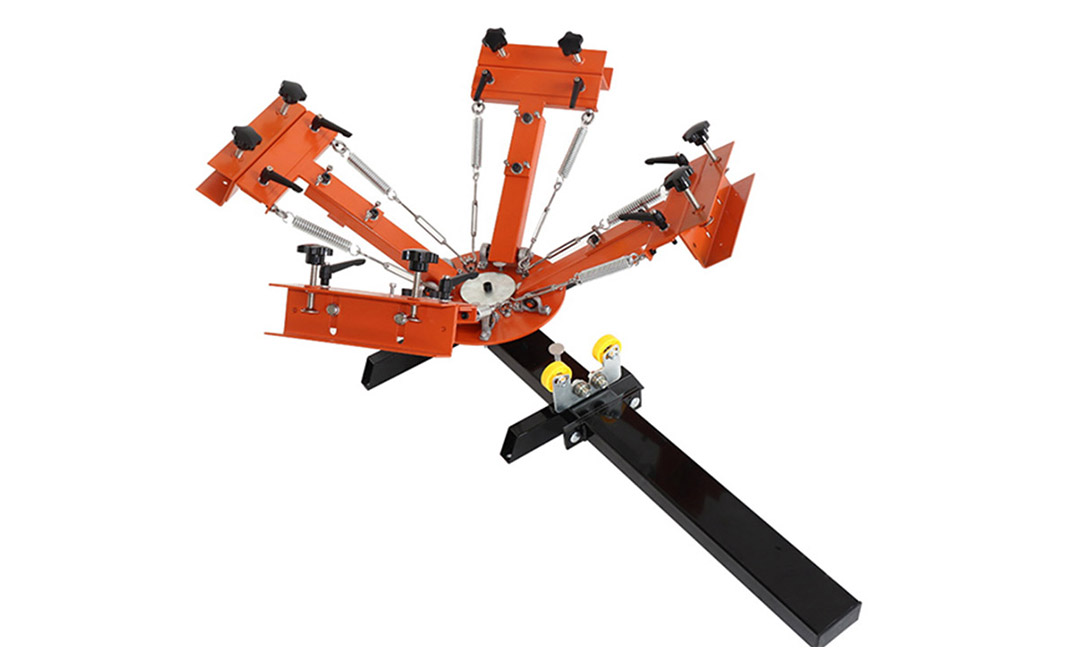

If you are looking to start your own screen printing business or upgrade your current equipment, the Riley Hopkins 150 4 Color 1 Station press is a popular choice among screen printers. This press is known for its durability, ease of use, and high-quality prints. In this article, we will provide you with a step-by-step guide on how to assemble the Riley Hopkins 150 4 Color 1 Station press.

Before you begin assembling the press, make sure you have all the necessary tools and equipment. You will need a set of wrenches, a screwdriver, and a level. It is also helpful to have a friend or colleague to assist you with the assembly process.

The first step in assembling the Riley Hopkins 150 4 Color 1 Station press is to unpack all the components and lay them out in an organized manner. Make sure to check that all the parts are included and in good condition before proceeding with the assembly.

Next, you will need to assemble the base of the press. Start by attaching the legs to the base using the provided screws and bolts. Make sure to tighten the screws securely to ensure stability. Once the legs are attached, use a level to ensure that the base is flat and even.

After assembling the base, it is time to attach the print head to the base. The print head is where the screens are mounted for printing. Use the provided screws and bolts to secure the print head to the base. Make sure that the print head is level and aligned with the base to ensure accurate prints.

Once the print head is attached, you can move on to installing the pallet arms. The pallet arms are used to hold the printing pallets in place. Attach the pallet arms to the print head using the provided screws and bolts. Make sure that the pallet arms are securely fastened to the print head to prevent any movement during printing.

After installing the pallet arms, you can attach the pallets to the arms. The pallets are where the garments are placed for printing. Make sure to align the pallets evenly and securely attach them to the arms using the provided screws.

The final step in assembling the Riley Hopkins 150 4 Color 1 Station press is to install the screen clamps. The screen clamps are used to hold the screens in place during printing. Attach the screen clamps to the print head using the provided screws and bolts. Make sure that the screen clamps are securely fastened to the print head to prevent any movement during printing.

Once you have completed all the steps outlined in this guide, your Riley Hopkins 150 4 Color 1 Station press should be fully assembled and ready for use. Remember to refer to the manufacturer’s instructions for any specific details or troubleshooting tips. With proper assembly and maintenance, your Riley Hopkins press will provide you with high-quality prints for years to come.

Tips for Properly Setting Up and Testing Riley Hopkins 150 4 Color 1 Station

Setting up a Riley Hopkins 150 4 Color 1 Station screen printing press can seem like a daunting task, especially for those who are new to the world of screen printing. However, with the right guidance and a step-by-step approach, you can have your press up and running in no time. In this article, we will walk you through the process of setting up and testing your Riley Hopkins 150 4 Color 1 Station press, ensuring that you are able to start printing with confidence.

The first step in setting up your Riley Hopkins press is to assemble the press itself. Start by laying out all of the components of the press, making sure that you have all of the necessary parts. Follow the manufacturer’s instructions carefully, ensuring that each piece is assembled correctly and securely. Once the press is fully assembled, you can move on to the next step.

Next, you will need to attach the screen clamps to the press. These clamps are essential for holding your screens in place while you print. Make sure that the clamps are securely attached to the press, and that they are positioned correctly for your specific printing needs. Once the clamps are in place, you can move on to setting up the screens themselves.

Before you can start printing, you will need to prepare your screens for use. Start by coating your screens with emulsion, following the manufacturer’s instructions carefully. Once the emulsion has dried, you can attach your screens to the press using the screen clamps. Make sure that the screens are securely in place, and that they are aligned correctly for your design.

With your screens in place, you can now move on to setting up your ink. Start by selecting the colors that you will be using for your print job, and then mix the ink according to the manufacturer’s instructions. Once the ink is mixed, you can load it into the appropriate color stations on the press. Make sure that the ink is evenly distributed in each station, and that the squeegees are clean and in good condition.

Now that your press is fully set up, it’s time to test it out. Start by running a test print on a scrap piece of fabric or paper, making sure that the design is coming out correctly and that the colors are printing evenly. If you encounter any issues, such as smudging or uneven printing, take the time to troubleshoot and make any necessary adjustments to the press.

Once you are satisfied with the test print, you can move on to printing your actual design. Load your screens with the appropriate ink colors, and then position your fabric or paper on the press. Lower the screen onto the substrate, making sure to apply even pressure with the squeegee. Lift the screen to reveal your printed design, and then repeat the process for each color in your design.

By following these steps and taking the time to properly set up and test your Riley Hopkins 150 4 Color 1 Station press, you can ensure that you are able to produce high-quality prints with ease. With practice and patience, you will soon become comfortable with the process and be able to create professional-looking prints for all of your screen printing projects.

Pre: Key Benefits of Using a 1 Station 4 Color Press for Small Businesses

Next: How to Maintain Your Riley Hopkins 150 1 Color 1 Station Machine

Tags: