Setting Up a Silkscreen Press for Home Use: What You Need to Know

Essential Equipment for Setting Up a Silkscreen Press at Home

Setting up a silkscreen press at home can be a rewarding and creative endeavor. Whether you are a seasoned screen printer or a beginner looking to try your hand at this art form, having the right equipment is essential to ensure successful printing results. In this article, we will discuss the essential equipment needed to set up a silkscreen press at home.

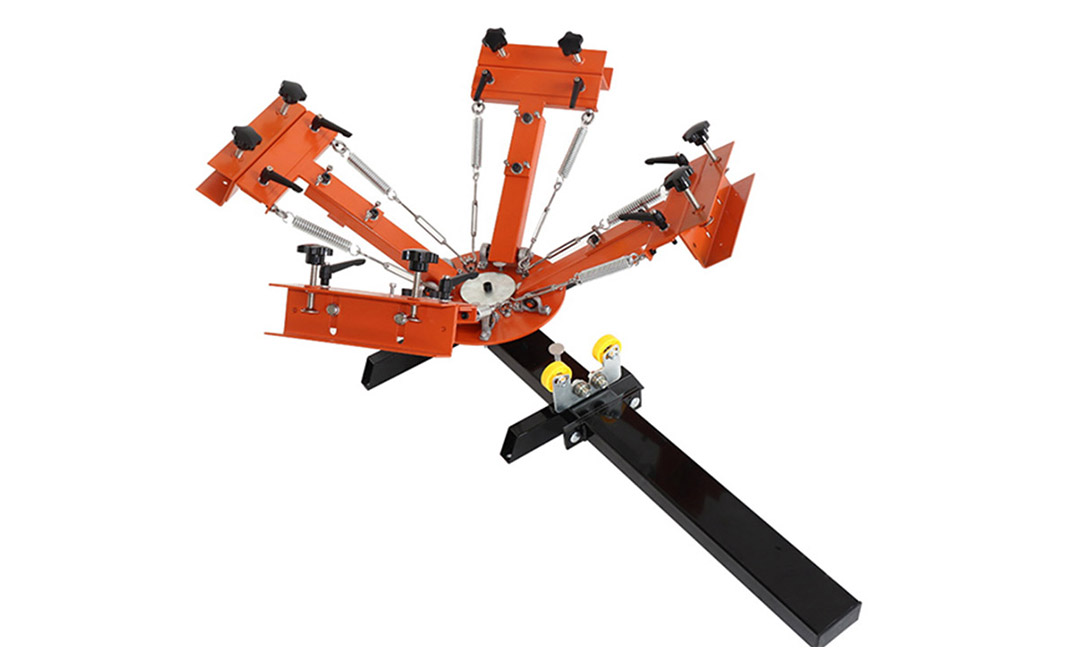

First and foremost, you will need a silkscreen press. This is the main piece of equipment that will hold your screen in place and allow you to apply ink to your desired surface. There are various types of silkscreen presses available, ranging from manual to automatic models. For home use, a manual press is typically more than sufficient and is also more affordable. Make sure to choose a press that is sturdy and well-built to ensure smooth and consistent printing.

Next, you will need screens. Screens are the foundation of the silkscreen printing process, as they hold the stencil that will transfer the design onto your chosen surface. Screens come in various mesh counts, which determine the level of detail and resolution that can be achieved in your prints. For beginners, a lower mesh count screen is recommended, as it is easier to work with and produces more opaque prints.

In addition to screens, you will also need a squeegee. The squeegee is used to push the ink through the screen and onto the surface being printed. Squeegees come in different sizes and shapes, so choose one that is appropriate for the size of your screen and the type of printing you will be doing. A good quality squeegee will ensure smooth and even ink application, resulting in crisp and clean prints.

Another essential piece of equipment for setting up a silkscreen press at home is a light source for exposing your screens. Exposure units are used to transfer your design onto the screen by exposing it to light through a film positive. While professional exposure units can be expensive, there are affordable DIY options available for home use, such as using a UV light box or even the sun on a sunny day. Whichever method you choose, make sure to follow proper exposure times to achieve the best results.

Lastly, you will need ink and emulsion for your silkscreen printing projects. Water-based inks are commonly used for home printing, as they are easy to work with and environmentally friendly. Emulsion is used to create the stencil on your screen and can be applied using a scoop coater. Make sure to choose the right type of emulsion for your specific printing needs, whether you are printing on fabric, paper, or other surfaces.

In conclusion, setting up a silkscreen press at home requires a few essential pieces of equipment to get started. By investing in a quality press, screens, squeegees, a light source for exposing screens, and ink and emulsion, you can create beautiful and professional-looking prints from the comfort of your own home. With the right equipment and a little practice, you can unleash your creativity and explore the endless possibilities of silkscreen printing.

Step-by-Step Guide to Setting Up Your Silkscreen Press

Setting up a silkscreen press for home use can be a rewarding and fulfilling experience for those who are passionate about screen printing. Whether you are a hobbyist looking to create unique designs or a small business owner wanting to expand your offerings, having a silkscreen press at home can open up a world of possibilities. However, setting up a silkscreen press can be a daunting task for beginners. In this article, we will provide you with a step-by-step guide on how to set up your silkscreen press for home use.

The first step in setting up your silkscreen press is to gather all the necessary materials and equipment. You will need a silkscreen frame, mesh fabric, squeegee, ink, emulsion, exposure unit, and a drying rack. Make sure to purchase high-quality materials to ensure the best results.

Once you have gathered all the necessary materials, the next step is to prepare your workspace. Choose a well-ventilated area with good lighting for your screen printing setup. Make sure to cover your work surface with a drop cloth or newspaper to protect it from ink spills.

The next step is to prepare your silkscreen frame. Stretch the mesh fabric tightly over the frame and secure it in place using staples or a screen adhesive. Make sure the mesh is taut and free of any wrinkles or creases. Once the mesh is securely attached to the frame, apply a coat of emulsion to the screen using a scoop coater. Allow the emulsion to dry completely before moving on to the next step.

After the emulsion has dried, it’s time to create your design. Use a computer program or hand-drawn stencil to create your design on a transparency film. Place the transparency film on top of the screen and secure it in place using tape. Make sure the design is centered and aligned properly on the screen.

Once your design is in place, it’s time to expose the screen. Place the screen in the exposure unit with the transparency film facing down. Turn on the exposure unit and expose the screen for the recommended amount of time. After the screen has been exposed, remove the transparency film and wash the screen with water to reveal your design.

Now that your screen is ready, it’s time to set up your printing station. Place the screen on the printing press and secure it in place using clamps. Load the squeegee with ink and flood the screen with ink using a smooth, even motion. Pull the squeegee across the screen in one fluid motion to transfer the ink onto the substrate.

After printing, carefully lift the screen off the substrate and place it on a drying rack to dry. Clean the screen thoroughly with water and a screen cleaner to remove any excess ink. Your silkscreen press is now set up and ready to use for your next printing project.

Setting up a silkscreen press for home use may seem like a daunting task, but with the right materials and equipment, it can be a rewarding and fulfilling experience. By following this step-by-step guide, you can set up your silkscreen press and start creating unique designs in no time. So gather your materials, prepare your workspace, and get ready to unleash your creativity with your very own silkscreen press.

Tips and Tricks for Maintaining and Troubleshooting Your Home Silkscreen Press

Setting up a silkscreen press for home use can be a rewarding and creative endeavor. Whether you are a seasoned screen printer or a beginner looking to try your hand at this art form, having your own press at home can open up a world of possibilities for creating custom designs on a variety of surfaces. However, like any piece of equipment, a silkscreen press requires proper maintenance and occasional troubleshooting to ensure it continues to produce high-quality prints. In this article, we will discuss some tips and tricks for maintaining and troubleshooting your home silkscreen press.

One of the most important aspects of maintaining your silkscreen press is keeping it clean. Regularly cleaning your press will help prevent ink buildup and ensure that your prints come out crisp and clear. To clean your press, start by removing any excess ink from the screen and squeegee. You can use a rag or paper towel soaked in a cleaning solution to wipe down the screen and squeegee. Be sure to also clean the frame and any other parts of the press that come into contact with ink.

In addition to regular cleaning, it is important to inspect your press for any signs of wear or damage. Check the tension of the screen and make sure it is properly secured in the frame. Inspect the hinges and bolts for any signs of rust or looseness. If you notice any issues, address them promptly to prevent further damage to your press.

Another important aspect of maintaining your silkscreen press is proper storage. When not in use, store your press in a clean, dry area away from direct sunlight and extreme temperatures. This will help prevent rust and other damage to the press. You may also want to cover your press with a dust cover to protect it from dust and debris.

If you encounter any issues with your silkscreen press, there are a few troubleshooting steps you can take to try and resolve the problem. If your prints are coming out blurry or smudged, check the tension of the screen and make sure it is properly aligned in the frame. You may also need to adjust the pressure of the squeegee or the angle at which it is held.

If your prints are not coming out evenly, check the level of the press and make sure it is on a stable surface. Uneven prints can also be caused by uneven pressure on the squeegee, so make sure you are applying consistent pressure across the entire screen.

If you are experiencing issues with ink bleeding or smearing, you may need to adjust the speed at which you pull the squeegee across the screen. Slower, more controlled movements can help prevent ink from bleeding into unwanted areas.

In conclusion, maintaining and troubleshooting your home silkscreen press is essential for producing high-quality prints. By keeping your press clean, inspecting it regularly for wear and damage, and storing it properly, you can ensure that your press continues to produce beautiful prints for years to come. If you encounter any issues with your press, try the troubleshooting tips mentioned above to resolve the problem. With proper care and maintenance, your home silkscreen press can be a valuable tool for unleashing your creativity and producing stunning designs.

Pre: Choosing the Right Emulsion for Your Screen Printing Projects

Next: How to Choose a Compact Screen Printing Press for Small Spaces

Tags: