Maximizing Results with a 4 Colour 1 Station Screen Printing Machine

Designing Efficient Workflows for 4 Colour 1 Station Screen Printing

Screen printing is a popular method of printing designs onto various surfaces, such as t-shirts, posters, and bags. One of the key factors in achieving high-quality results with screen printing is having an efficient workflow. This is especially important when using a 4 colour 1 station screen printing machine, as it allows for multiple colours to be printed in a single pass. By designing an efficient workflow, you can maximize the results you achieve with this type of machine.

One of the first steps in designing an efficient workflow for a 4 colour 1 station screen printing machine is to carefully plan out your design. Consider how many colours you will be using, and how they will interact with each other on the final product. By planning out your design in advance, you can ensure that each colour is printed in the correct order and that the final product looks as intended.

Once you have your design planned out, the next step is to prepare your screens. Each colour in your design will require its own screen, so make sure to prepare each screen carefully. This includes coating the screen with emulsion, exposing it to your design, and washing out the excess emulsion to create the stencil for each colour. By taking the time to properly prepare your screens, you can ensure that each colour is printed accurately and that your final product looks professional.

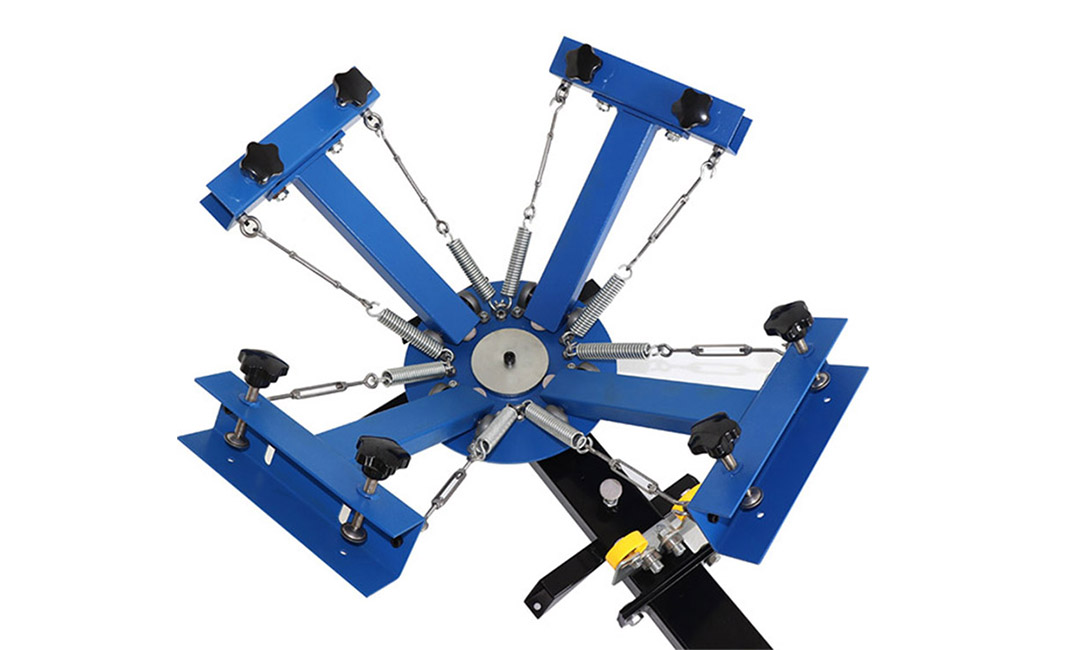

After preparing your screens, it’s time to set up your 4 colour 1 station screen printing machine. Make sure to carefully align each screen on the machine so that the colours line up correctly when printed. This may require some trial and error, but taking the time to properly align your screens will result in a higher quality final product.

Once your screens are aligned, it’s time to start printing. When using a 4 colour 1 station screen printing machine, it’s important to print each colour in the correct order. Start with the lightest colour and work your way up to the darkest colour, as this will prevent any bleeding or mixing of colours. By following this order, you can ensure that each colour is printed accurately and that the final product looks as intended.

As you print each colour, make sure to carefully inspect the results. If there are any mistakes or imperfections, take the time to correct them before moving on to the next colour. This may require adjusting the alignment of the screens, adjusting the pressure of the squeegee, or making other minor adjustments to the machine. By taking the time to correct any mistakes as you go, you can ensure that the final product meets your standards.

In conclusion, designing an efficient workflow for a 4 colour 1 station screen printing machine is essential for maximizing the results you achieve. By carefully planning out your design, preparing your screens, aligning your screens on the machine, printing each colour in the correct order, and inspecting the results as you go, you can ensure that the final product looks professional and meets your standards. With a well-designed workflow, you can achieve high-quality results with a 4 colour 1 station screen printing machine.

Tips for Achieving Vibrant and Accurate Colors with a 4 Colour 1 Station Screen Printing Machine

Screen printing is a popular method for creating vibrant and accurate designs on various surfaces, from t-shirts to posters. One of the key factors in achieving high-quality results with screen printing is the use of a 4 colour 1 station screen printing machine. This type of machine allows for the printing of designs with up to four different colors, making it ideal for creating intricate and colorful designs.

To maximize the results with a 4 colour 1 station screen printing machine, there are several tips and techniques that can be employed. One of the most important factors to consider is the selection of high-quality inks. Using inks that are specifically designed for screen printing will ensure that the colors are vibrant and long-lasting. It is also important to properly mix the inks to achieve the desired colors and consistency.

Another important aspect of achieving vibrant and accurate colors with a 4 colour 1 station screen printing machine is the use of high-quality screens. The screens used in screen printing are responsible for transferring the ink onto the surface, so it is essential to use screens that are durable and have a high mesh count. This will help to ensure that the colors are applied evenly and accurately.

In addition to using high-quality inks and screens, it is also important to properly set up the 4 colour 1 station screen printing machine. This includes adjusting the tension of the screens, aligning the colors correctly, and ensuring that the machine is running smoothly. Proper maintenance of the machine is also crucial to achieving consistent and accurate results.

When printing with a 4 colour 1 station screen printing machine, it is important to pay attention to the order in which the colors are printed. This can have a significant impact on the final result, as certain colors may need to be printed first to ensure that they are properly layered. It is also important to allow each color to dry completely before printing the next color to prevent smudging or bleeding.

To achieve the best results with a 4 colour 1 station screen printing machine, it is important to experiment with different techniques and settings. This may involve adjusting the pressure of the squeegee, the speed of the machine, or the angle at which the screens are placed. By taking the time to test different methods, it is possible to achieve the desired results and create stunning designs.

In conclusion, maximizing the results with a 4 colour 1 station screen printing machine requires attention to detail, the use of high-quality materials, and experimentation with different techniques. By following these tips and techniques, it is possible to achieve vibrant and accurate colors that will make any design stand out. With practice and patience, anyone can master the art of screen printing and create stunning designs with a 4 colour 1 station screen printing machine.

Utilizing Specialty Inks and Techniques to Enhance Results with a 4 Colour 1 Station Screen Printing Machine

Screen printing is a versatile and popular method of printing that allows for high-quality, durable prints on a variety of surfaces. One of the key factors in achieving great results with screen printing is the use of specialty inks and techniques. By utilizing these inks and techniques, you can enhance the quality and visual appeal of your prints, even when working with a 4 colour 1 station screen printing machine.

One of the most common specialty inks used in screen printing is metallic ink. Metallic inks contain metallic particles that give the print a shiny, reflective finish. These inks can add a touch of elegance and sophistication to your prints, making them stand out from the crowd. When using metallic inks with a 4 colour 1 station screen printing machine, it’s important to ensure that the ink is properly mixed and applied to achieve the desired effect.

Another popular specialty ink for screen printing is glow-in-the-dark ink. Glow-in-the-dark ink contains phosphorescent pigments that absorb and store light energy, then release it in the form of a soft glow in the dark. This ink is perfect for creating eye-catching prints that are sure to grab attention. When using glow-in-the-dark ink with a 4 colour 1 station screen printing machine, it’s important to ensure that the ink is properly cured to maximize its glow-in-the-dark properties.

In addition to specialty inks, there are also a variety of techniques that can be used to enhance the results of screen printing with a 4 colour 1 station machine. One such technique is halftone printing. Halftone printing involves using dots of varying sizes and spacing to create the illusion of different shades of color. This technique is perfect for creating detailed and realistic prints with a limited color palette.

Another technique that can be used to enhance the results of screen printing is the use of specialty screens. Specialty screens are screens that have been specially designed to create unique effects in the print. For example, you can use a specialty screen with a pattern or texture to add depth and dimension to your prints. When using specialty screens with a 4 colour 1 station screen printing machine, it’s important to ensure that the screen is properly aligned and secured to achieve the desired effect.

By utilizing specialty inks and techniques, you can maximize the results of screen printing with a 4 colour 1 station machine. Whether you’re looking to add a touch of elegance with metallic inks, create eye-catching prints with glow-in-the-dark ink, or enhance the detail and realism of your prints with halftone printing, there are endless possibilities for creating stunning prints with screen printing. With the right inks, techniques, and equipment, you can take your screen printing to the next level and create prints that are sure to impress.

Pre: Why Riley Hopkins 4 Color 1 Station Press Is Perfect for Professionals

Tags: