Maximizing Color Accuracy with a Multi-Color Screen Printing Press

The Importance of Color Accuracy in Screen Printing

Color accuracy is a crucial aspect of screen printing, as it directly impacts the quality and consistency of the final product. Achieving accurate colors can be challenging, especially when working with multiple colors in a design. However, with the right tools and techniques, it is possible to maximize color accuracy and produce high-quality prints.

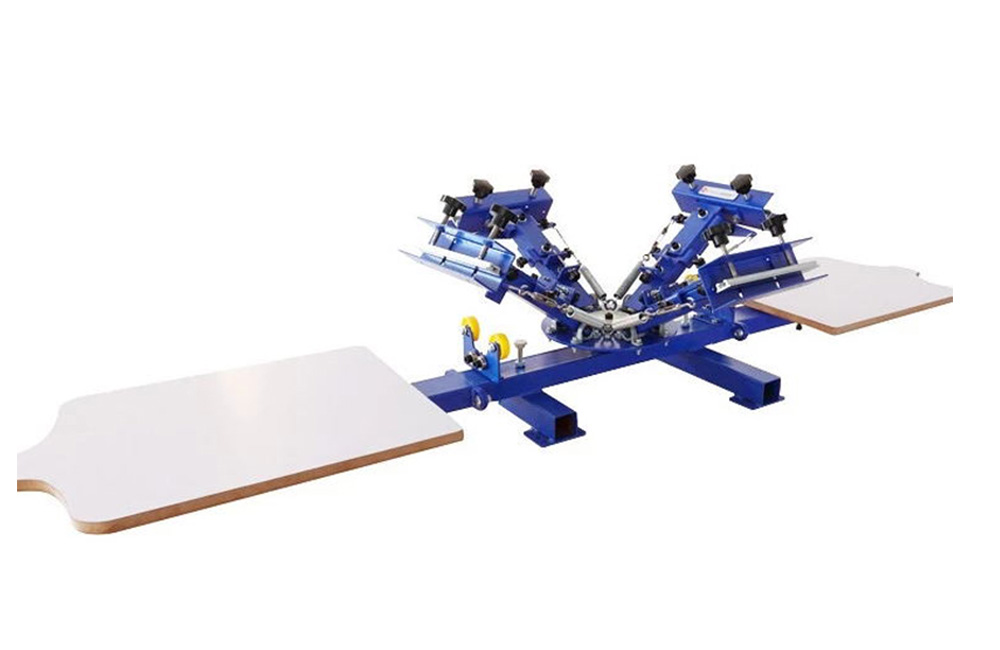

One of the key tools for achieving color accuracy in screen printing is a multi-color screen printing press. This type of press allows for the printing of multiple colors in a single pass, which can help to ensure that the colors in the final print are aligned correctly and match the original design. By using a multi-color press, printers can reduce the risk of misalignment and color inconsistencies, resulting in a more accurate and professional-looking print.

In addition to using a multi-color press, there are several other techniques that can help to maximize color accuracy in screen printing. One important technique is to use high-quality inks that are specifically designed for screen printing. These inks are formulated to provide vibrant, long-lasting colors that will not fade or bleed during the printing process. By using high-quality inks, printers can ensure that the colors in their prints are accurate and true to the original design.

Another important technique for maximizing color accuracy is to properly calibrate the printing press and screens. Calibration involves adjusting the settings on the press and screens to ensure that the colors are being printed accurately. This can involve adjusting the tension of the screens, the pressure of the squeegee, and the speed of the press. By calibrating the press and screens, printers can ensure that the colors in their prints are consistent and accurate across all copies.

It is also important to use a color management system when working with multiple colors in screen printing. A color management system helps to ensure that the colors in the design are accurately reproduced on the final print. This system can involve using color profiles, color swatches, and color matching software to ensure that the colors in the design are accurately translated to the final print. By using a color management system, printers can reduce the risk of color inconsistencies and ensure that the final print matches the original design.

In conclusion, maximizing color accuracy in screen printing is essential for producing high-quality prints. By using a multi-color screen printing press, high-quality inks, proper calibration techniques, and a color management system, printers can ensure that the colors in their prints are accurate and consistent. By taking the time to implement these techniques, printers can achieve professional-looking prints that accurately reflect the original design.

Pre: Why Tabletop Screen Printing Presses Are Perfect for Small Spaces

Next: Comparing Tabletop Screen Printing Presses: Which One Is Right for You?

Tags: