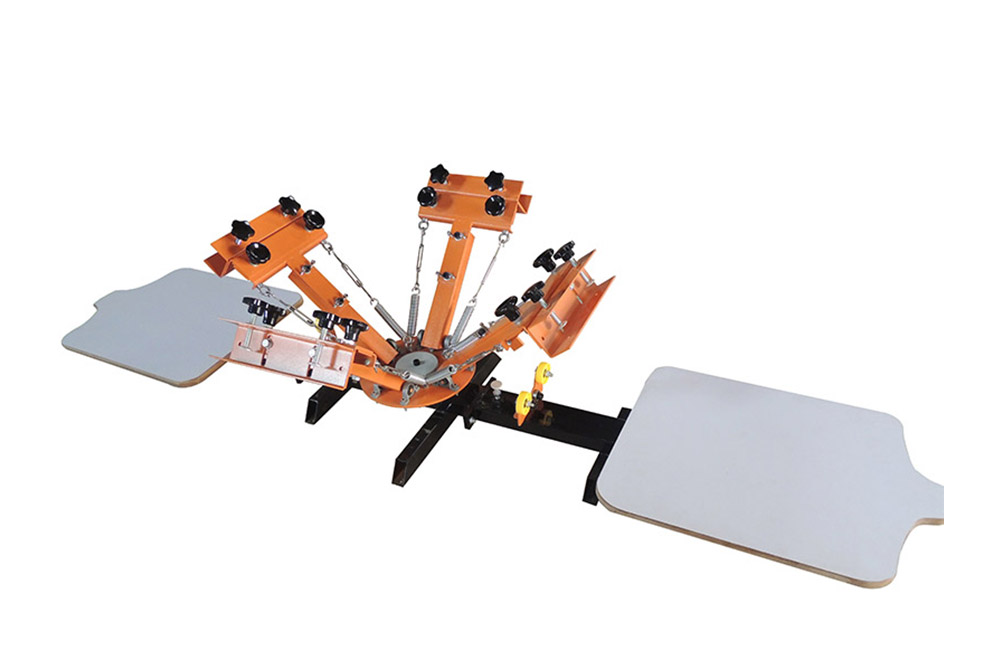

Maintenance Tips for Your 4 Color Silk Screen Printing Machine

Regular Cleaning and Maintenance Schedule

Maintaining a 4 color silk screen printing machine is essential to ensure its longevity and optimal performance. Regular cleaning and maintenance are key to preventing breakdowns and costly repairs. By following a few simple tips, you can keep your machine running smoothly and producing high-quality prints.

First and foremost, it is important to establish a regular cleaning and maintenance schedule for your 4 color silk screen printing machine. This will help you stay on top of any potential issues and address them before they become major problems. Set aside time each week to inspect the machine and perform routine maintenance tasks.

One of the most important maintenance tasks is cleaning the machine after each use. Ink residue can build up on the screens, squeegees, and other components, leading to poor print quality and potential damage to the machine. Use a mild detergent and water to clean the screens and squeegees, making sure to remove all traces of ink. Wipe down the machine with a clean, dry cloth to remove any excess ink or debris.

In addition to regular cleaning, it is important to lubricate the moving parts of the machine to prevent wear and tear. Use a high-quality lubricant recommended by the manufacturer to keep the machine running smoothly. Be sure to follow the manufacturer’s guidelines for lubrication frequency and application.

Inspect the machine for any signs of wear or damage, such as loose screws, frayed wires, or cracked components. Address any issues immediately to prevent further damage and ensure the machine’s continued operation. Keep a log of any maintenance tasks performed and note any issues that need to be addressed in the future.

It is also important to keep the machine in a clean and dust-free environment to prevent contamination of the screens and other components. Cover the machine when not in use to protect it from dust and debris. Regularly vacuum the area around the machine to remove any loose particles that could affect print quality.

In addition to regular cleaning and maintenance, it is important to follow the manufacturer’s guidelines for operating the machine. Avoid overloading the machine with too much ink or applying too much pressure to the screens, as this can cause damage to the machine and affect print quality. Use high-quality inks and materials recommended by the manufacturer to ensure the best results.

By following these maintenance tips and establishing a regular cleaning schedule, you can keep your 4 color silk screen printing machine in top condition and ensure its continued performance. Regular maintenance will not only extend the life of the machine but also help you produce high-quality prints consistently. Take the time to care for your machine, and it will reward you with years of reliable service.

Pre: Tips for Beginners Using a Multi-Color Screen Printing Press

Next: Key Features to Look for in a T-Shirt Screen Printing Machine

Tags: