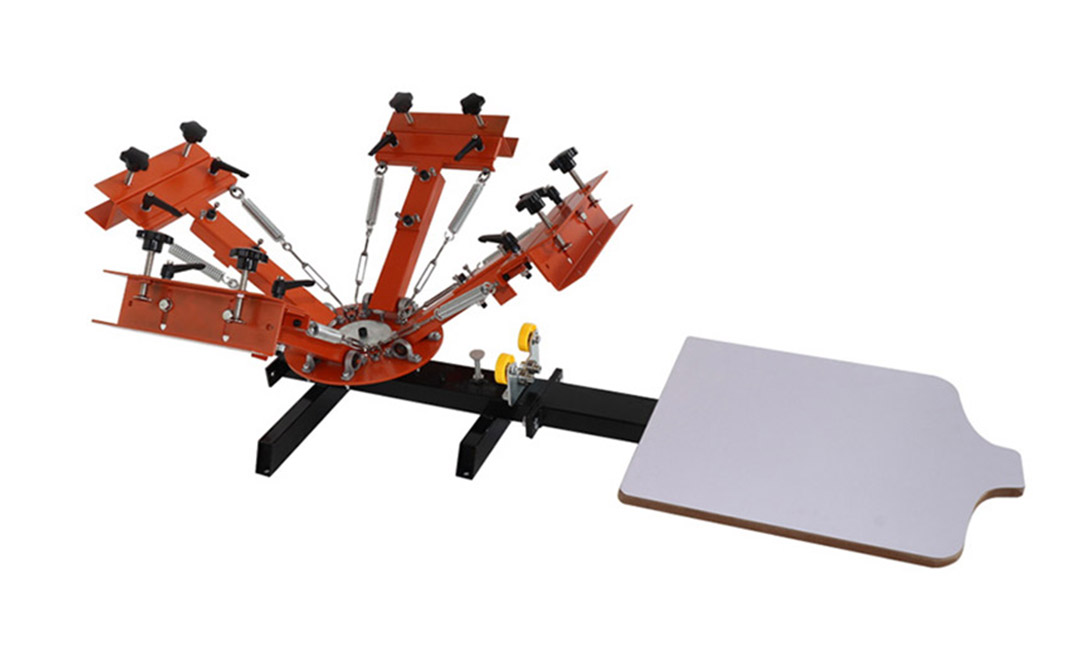

Maintenance Tips for a Long-Lasting 4 Color 1 Station Screen Printing Machine

Regular Cleaning and Lubrication

Maintaining a 4 color 1 station screen printing machine is essential to ensure its longevity and optimal performance. Regular cleaning and lubrication are key aspects of machine maintenance that should not be overlooked. By following these maintenance tips, you can extend the life of your screen printing machine and avoid costly repairs.

To begin, it is important to clean your screen printing machine after each use. This will prevent ink buildup and ensure that the machine operates smoothly. Start by wiping down the machine with a damp cloth to remove any excess ink or debris. Pay special attention to the screen, squeegees, and platens, as these are the areas most prone to buildup. Use a mild detergent or cleaning solution to thoroughly clean these components, being careful not to damage the sensitive parts of the machine.

In addition to regular cleaning, lubricating the moving parts of the screen printing machine is crucial for smooth operation. Apply a small amount of lubricant to the hinges, bearings, and other moving parts to reduce friction and prevent wear and tear. Be sure to use a lubricant that is compatible with the materials used in your machine to avoid damage. Regular lubrication will help keep your machine running smoothly and prevent unnecessary strain on the components.

Another important aspect of maintenance is checking for loose or damaged parts. Inspect the machine regularly for any signs of wear or damage, such as loose screws, cracked components, or frayed cables. Tighten any loose screws and replace any damaged parts to prevent further issues. By addressing these issues promptly, you can prevent more serious problems from occurring and prolong the life of your screen printing machine.

It is also important to store your screen printing machine properly when not in use. Keep the machine covered or stored in a clean, dry area to protect it from dust, moisture, and other contaminants. This will help prevent damage and ensure that the machine is ready for use when needed. Additionally, follow the manufacturer’s guidelines for storing the machine to avoid any potential issues.

In conclusion, regular cleaning and lubrication are essential maintenance tasks for a 4 color 1 station screen printing machine. By following these tips, you can keep your machine in top condition and avoid costly repairs. Remember to clean the machine after each use, lubricate the moving parts, check for loose or damaged components, and store the machine properly. By taking care of your screen printing machine, you can ensure that it continues to produce high-quality prints for years to come.

Pre: DIY T-Shirt Printing: Mastering the 4 Color 1 Station Screen Printing Process

Next: How to Start Your Business with a 4 Color 1 Station Screen Printing Setup

Tags: