How to Upgrade Your Screen Printing Setup for Faster Production

Optimizing Your Workspace Layout

Screen printing is a popular method for creating high-quality prints on various materials, such as t-shirts, posters, and signage. If you’re looking to increase your production speed and efficiency, upgrading your screen printing setup is essential. One key aspect to consider when optimizing your screen printing setup is your workspace layout.

The layout of your screen printing workspace can have a significant impact on your production speed and efficiency. A well-organized workspace can help streamline your workflow, reduce downtime, and improve overall productivity. Here are some tips on how to upgrade your screen printing setup for faster production by optimizing your workspace layout.

First and foremost, it’s essential to assess your current workspace layout and identify any areas that may be causing bottlenecks or inefficiencies. Take a close look at the flow of your production process, from pre-press preparation to printing and curing. Are there any areas where workers are frequently getting in each other’s way? Are there any unnecessary steps or movements that could be eliminated?

Once you’ve identified any potential issues with your current workspace layout, it’s time to make some changes. One effective way to optimize your screen printing setup is to create designated workstations for each step of the production process. For example, you could have a separate workstation for pre-press preparation, printing, and curing. This can help prevent workers from getting in each other’s way and ensure that each step of the process is completed efficiently.

Another important aspect of optimizing your workspace layout is to ensure that all necessary tools and supplies are easily accessible. Consider installing shelving units or storage bins to keep screens, inks, squeegees, and other supplies organized and within reach. This can help reduce downtime caused by searching for misplaced tools or supplies and improve overall efficiency.

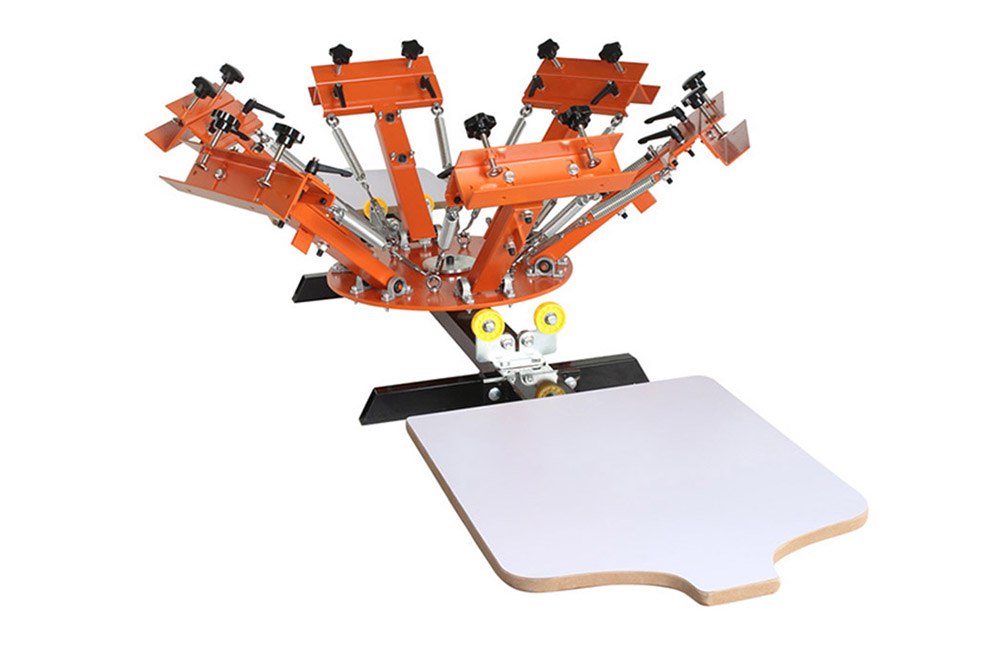

In addition to creating designated workstations and organizing your tools and supplies, it’s also important to consider the layout of your equipment. Make sure that your screen printing press is positioned in a way that allows for easy access to all sides of the machine. This can help facilitate quick screen changes and adjustments, reducing downtime and increasing production speed.

Furthermore, consider the layout of your drying and curing equipment. Make sure that your drying racks or conveyor dryer are positioned in a way that allows for easy loading and unloading of printed materials. This can help ensure that prints are cured quickly and efficiently, allowing for faster turnaround times.

Overall, optimizing your workspace layout is essential for upgrading your screen printing setup for faster production. By creating designated workstations, organizing your tools and supplies, and positioning your equipment for easy access, you can streamline your workflow, reduce downtime, and improve overall efficiency. With a well-organized and efficient workspace layout, you can take your screen printing business to the next level and increase your production speed and output.

Pre: Why Professional Printers Choose a Multi-Color Screen Printing Press

Next: How to Print Specialty Inks with a 4 Color 2 Station Screen Printing Machine

Tags: