How to Set Up Your First Screen Printing Station for Success

Essential Equipment Needed for a Screen Printing Station

Screen printing is a popular method of printing designs onto various surfaces, such as t-shirts, posters, and bags. If you’re interested in starting your own screen printing business or simply want to try your hand at this creative process, setting up a screen printing station is the first step towards success. In this article, we will discuss the essential equipment needed to set up your first screen printing station.

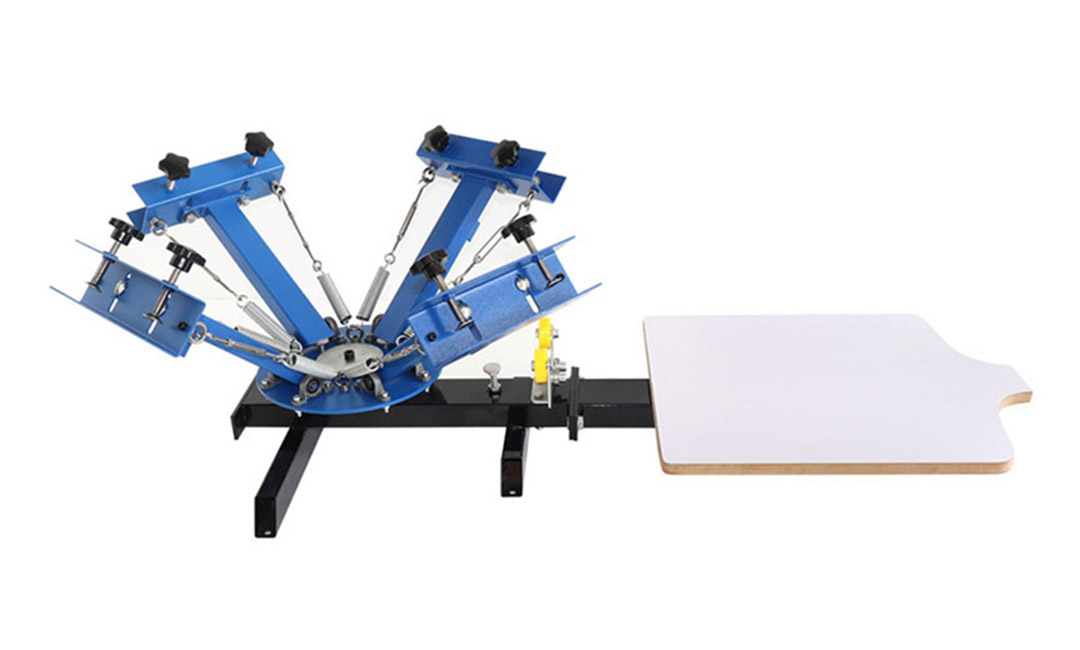

The most important piece of equipment you will need for your screen printing station is a screen printing press. This press holds the screen in place and allows you to apply ink to the design with precision. There are various types of screen printing presses available, ranging from manual to automatic models. For beginners, a manual press is a good option as it is more affordable and easier to learn how to use.

In addition to a screen printing press, you will also need screens, squeegees, and ink. Screens are used to transfer the design onto the surface you are printing on, while squeegees are used to push the ink through the screen and onto the surface. When choosing screens, make sure to select the appropriate mesh count for the type of design you are printing. As for ink, there are different types available, such as water-based and plastisol inks. It’s important to choose the right ink for your project to ensure the best results.

Another essential piece of equipment for your screen printing station is a flash dryer. This device is used to cure the ink after it has been applied to the surface. Curing the ink ensures that it is durable and long-lasting. Flash dryers come in various sizes and styles, so make sure to choose one that fits your needs and budget.

To properly clean your screens and squeegees, you will need a screen cleaning system. This system typically includes a washout booth, pressure washer, and screen cleaning chemicals. Properly cleaning your screens and squeegees is essential for maintaining the quality of your prints and prolonging the life of your equipment.

Lastly, you will need a drying rack to dry your prints after they have been cured. Drying racks come in various sizes and styles, so choose one that fits the space available in your screen printing station. A drying rack is essential for keeping your prints organized and preventing them from smudging or sticking together.

In conclusion, setting up a screen printing station requires several essential pieces of equipment, including a screen printing press, screens, squeegees, ink, a flash dryer, a screen cleaning system, and a drying rack. By investing in quality equipment and taking the time to learn how to use it properly, you can set up your first screen printing station for success. With practice and dedication, you can create beautiful prints and build a successful screen printing business.

Step-by-Step Guide to Setting Up Your Screen Printing Station

Screen printing is a popular method of printing designs onto various surfaces, such as t-shirts, posters, and bags. If you’re interested in starting your own screen printing business or simply want to try your hand at this creative process, setting up a screen printing station is the first step towards success. In this article, we will provide you with a step-by-step guide on how to set up your first screen printing station for success.

The first step in setting up your screen printing station is to choose a suitable location. Ideally, you should have a dedicated space that is well-ventilated and has access to water and electricity. A garage or spare room can make a great screen printing studio, as long as it meets these requirements.

Once you have chosen a location, the next step is to invest in the necessary equipment. You will need a screen printing press, screens, squeegees, inks, and a drying rack. It’s important to choose high-quality equipment that will last and produce professional results. You can find screen printing kits online or at your local art supply store.

After you have gathered all the necessary equipment, it’s time to set up your screen printing station. Start by setting up your screen printing press in a sturdy and level surface. Make sure that the press is securely anchored to prevent any accidents during printing.

Next, prepare your screens by coating them with emulsion and allowing them to dry in a dark room. Once the screens are dry, you can start preparing your designs. Use a computer program or hand-drawn sketches to create your designs, and then transfer them onto the screens using a light table or exposure unit.

Once your screens are ready, it’s time to set up your inks and squeegees. Place your inks in a well-organized area where they are easily accessible, and make sure that your squeegees are clean and in good condition. You may also want to invest in a screen printing ink mixer to ensure that your colors are consistent.

Now that everything is set up, it’s time to start printing! Place your garment or surface on the printing platen of the press, and position your screen on top of it. Apply a generous amount of ink to the screen, and use the squeegee to pull the ink across the design. Lift the screen to reveal your printed design, and place the garment on the drying rack to dry.

As you continue to print, make sure to clean your screens and squeegees regularly to prevent ink buildup and ensure crisp prints. It’s also important to experiment with different techniques and designs to find what works best for you.

In conclusion, setting up your first screen printing station can be a rewarding and creative process. By following this step-by-step guide, you can create a successful screen printing station that will allow you to bring your designs to life. With practice and dedication, you can master the art of screen printing and create stunning prints that will impress your customers.

Tips for Maintaining and Optimizing Your Screen Printing Station

Screen printing is a popular method of printing designs onto various surfaces, such as t-shirts, posters, and bags. Setting up your first screen printing station can be a daunting task, but with the right tools and knowledge, you can create a successful printing station that will produce high-quality prints. In this article, we will provide you with tips for maintaining and optimizing your screen printing station to ensure that it runs smoothly and efficiently.

One of the most important aspects of setting up a screen printing station is choosing the right equipment. You will need a screen printing press, screens, squeegees, inks, and a drying rack. It is essential to invest in high-quality equipment to ensure that your prints turn out well. Additionally, make sure to have a designated space for your screen printing station that is well-ventilated and has good lighting.

Once you have all the necessary equipment, it is important to properly set up your screen printing station. Start by securing your screen printing press to a sturdy table or workbench. Make sure that the press is level and stable to prevent any accidents while printing. Next, attach your screens to the press and secure them tightly to ensure that they do not move during the printing process.

After setting up your equipment, it is crucial to maintain your screen printing station regularly. Clean your screens and squeegees after each use to prevent ink from drying and clogging the screen. Additionally, check your equipment for any signs of wear and tear and replace any damaged parts as needed. By maintaining your screen printing station, you can ensure that it continues to produce high-quality prints.

To optimize your screen printing station, consider experimenting with different inks and printing techniques. Try using different types of inks, such as water-based or plastisol inks, to see which works best for your designs. Additionally, experiment with different printing techniques, such as halftone printing or discharge printing, to create unique and interesting prints.

Another way to optimize your screen printing station is to invest in a good quality drying rack. A drying rack will allow your prints to dry evenly and prevent smudging or smearing. Make sure to place your prints on the drying rack immediately after printing to ensure that they dry properly.

In conclusion, setting up your first screen printing station for success requires careful planning and attention to detail. By choosing the right equipment, properly setting up your station, maintaining your equipment regularly, and experimenting with different inks and printing techniques, you can create a successful screen printing station that produces high-quality prints. Remember to always clean your equipment after each use and invest in a good quality drying rack to optimize your printing station. With these tips in mind, you can create a successful screen printing station that will help you achieve your printing goals.

Pre: Starting a Side Hustle with Screen Printing: A Step-by-Step Guide

Next: What is Screen Printing Emulsion and How to Use It Effectively

Tags: