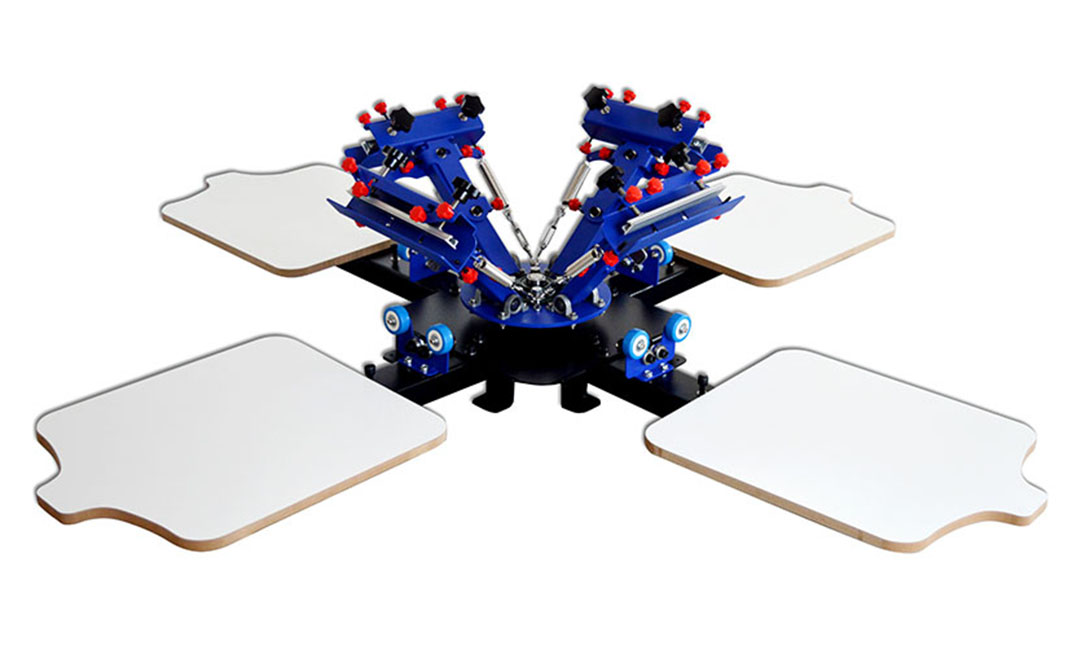

How to Set Up the Silk Screen Printing Machine 4 Color 4 Station for Optimal Performance

Preparing the Workspace for Silk Screen Printing

Setting up a silk screen printing machine, particularly a 4 color 4 station model, requires careful preparation of the workspace to ensure optimal performance and efficiency. The first step in this process is to select an appropriate location that is spacious, well-lit, and free from distractions. A clean, organized environment not only enhances productivity but also minimizes the risk of contamination, which can adversely affect the quality of the prints. Ideally, the workspace should be equipped with ample electrical outlets to accommodate the machine and any additional equipment, such as exposure units or drying racks.

Once the location is established, the next consideration is the work surface. A sturdy, level table is essential for supporting the silk screen printing machine. It is advisable to use a table that is at a comfortable height to reduce strain during operation. Additionally, the surface should be resistant to spills and easy to clean, as ink and emulsion can create a mess. Placing a protective mat underneath the machine can further safeguard the table and facilitate easier cleanup.

After ensuring that the work surface is suitable, it is important to organize the necessary tools and materials. This includes screens, squeegees, inks, emulsion, and other printing supplies. Having these items within easy reach will streamline the printing process and reduce downtime. It is beneficial to use storage bins or shelves to keep everything organized, allowing for quick access to materials when needed. Furthermore, labeling containers can help maintain order and ensure that supplies are replenished as necessary.

In addition to organizing tools and materials, proper ventilation is crucial in a silk screen printing workspace. Many inks and solvents emit fumes that can be harmful if inhaled over extended periods. Therefore, it is advisable to set up the workspace near a window or in a well-ventilated area. If natural ventilation is not possible, investing in an exhaust fan or air filtration system can significantly improve air quality, making the environment safer for prolonged use.

Moreover, it is essential to consider the lighting in the workspace. Adequate lighting is vital for accurately aligning screens and ensuring that prints are applied correctly. Natural light is ideal, but if that is not available, bright, adjustable LED lights can provide the necessary illumination. Positioning lights to minimize shadows will enhance visibility and precision during the printing process.

As the workspace is being prepared, it is also important to establish a workflow that maximizes efficiency. This involves planning the layout of the machine and surrounding tools to facilitate smooth movement between different stages of the printing process. For instance, placing the drying rack close to the printing station can reduce the time spent transporting prints, while ensuring that screens are easily accessible will streamline setup and cleanup.

Finally, before beginning any printing, it is advisable to conduct a thorough inspection of the silk screen printing machine itself. Checking for any loose parts, ensuring that the squeegees are in good condition, and confirming that the screens are properly tensioned will help prevent issues during operation. By taking the time to prepare the workspace meticulously, operators can set the stage for successful silk screen printing, ultimately leading to high-quality results and a more enjoyable printing experience.

Pre: Why USA-Made 4 Color 4 Station Screen Printing Machines Are Known for Durability

Next: Is the Price of a 4 Color 4 Station T-Shirt Printing Machine Worth It?

Tags: