How to Set Up and Maintain a 4 Color 4 Station Screen Printing Machine

Choosing the Right Screen Printing Machine

Screen printing is a popular method of printing designs onto various surfaces, such as t-shirts, posters, and bags. One of the key components of screen printing is the screen printing machine. When setting up and maintaining a 4 color 4 station screen printing machine, there are several important steps to follow to ensure smooth operation and high-quality prints.

First and foremost, it is crucial to choose the right screen printing machine for your needs. There are many different types of screen printing machines available on the market, ranging from manual to automatic models. When selecting a machine, consider factors such as the size of your workspace, the volume of prints you plan to produce, and your budget.

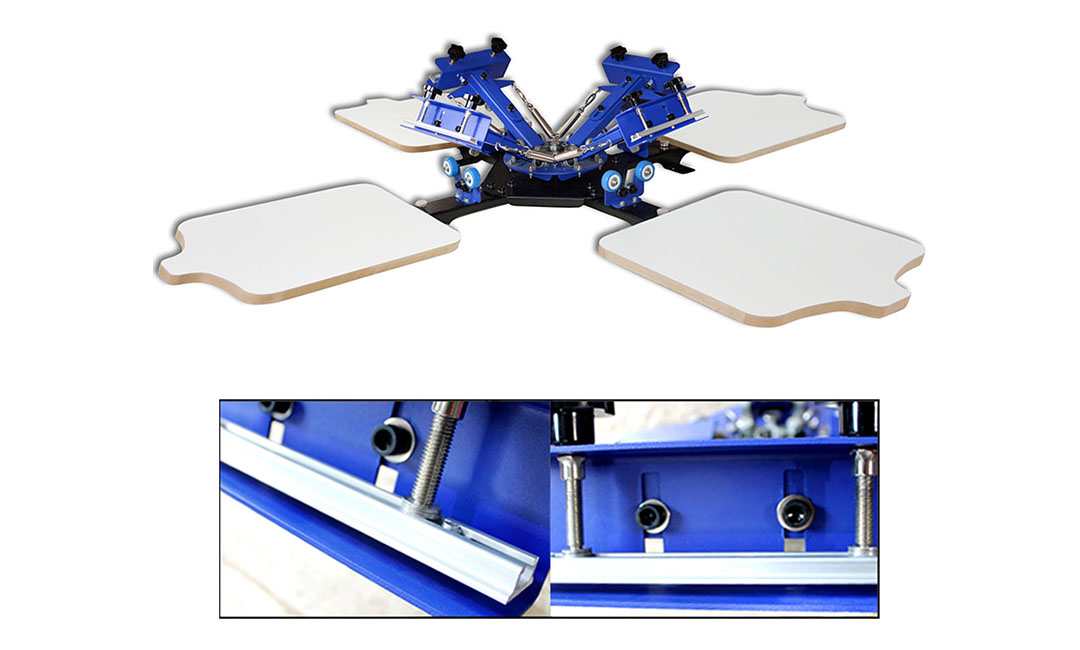

Once you have chosen a 4 color 4 station screen printing machine, it is time to set it up. Start by assembling the machine according to the manufacturer’s instructions. Make sure all parts are securely attached and in proper working order. Next, install the screens onto the machine, making sure they are properly tensioned and aligned. This will ensure that your prints come out crisp and clear.

After setting up the machine, it is important to maintain it properly to ensure longevity and optimal performance. Regular maintenance tasks include cleaning the screens, squeegees, and ink trays after each use. This will prevent ink buildup and ensure that your prints are consistent and vibrant. Additionally, check for any loose or damaged parts and replace them as needed.

In addition to regular maintenance, it is important to troubleshoot any issues that may arise with your screen printing machine. Common problems include uneven prints, ink smudges, and registration errors. To address these issues, start by checking the alignment of the screens and squeegees. Adjust as needed to ensure that the prints are coming out correctly.

If you are experiencing ink smudges, check the tension of the screens and make sure they are properly secured. Additionally, check the pressure of the squeegees and adjust as needed. For registration errors, double-check the alignment of the screens and make any necessary adjustments.

In conclusion, setting up and maintaining a 4 color 4 station screen printing machine requires careful attention to detail and regular maintenance. By choosing the right machine, following proper setup procedures, and conducting regular maintenance tasks, you can ensure that your screen printing machine operates smoothly and produces high-quality prints. Troubleshooting any issues that may arise will help you address problems quickly and keep your machine running efficiently. With proper care and maintenance, your screen printing machine will continue to produce beautiful prints for years to come.

Pre: Why Choose a USA-Made 4 Color 4 Station Screen Printing T-Shirt Machine?

Next: Lick 4-Color Garment Screen Printing Machine: Unmatched Versatility

Tags: