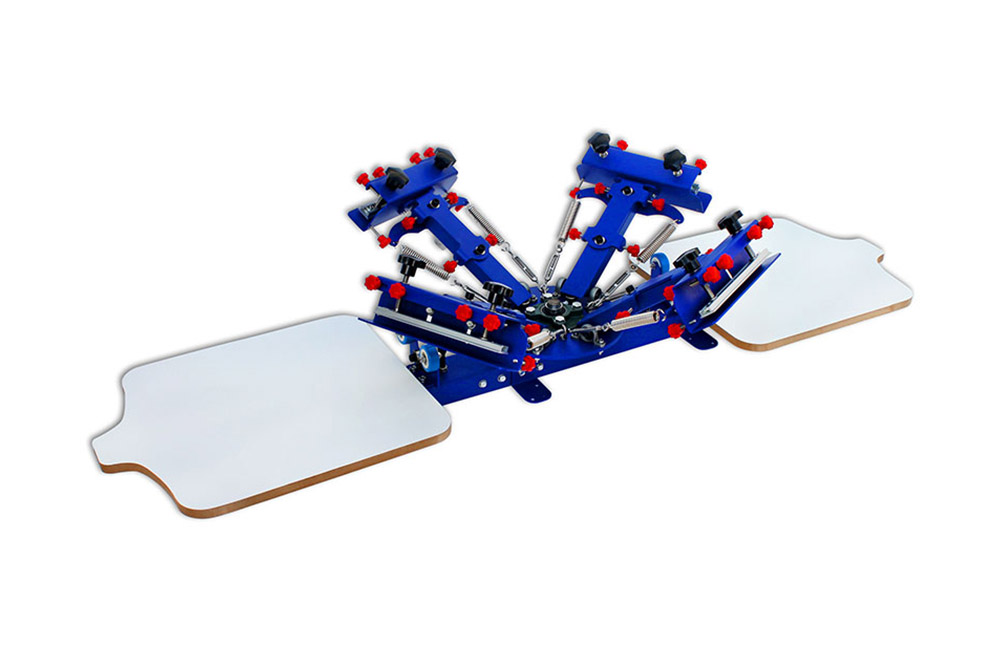

How to Print Multi-Layer Designs with a Small Screen Printing Machine

Tips for Printing Multi-Layer Designs with a Small Screen Printing Machine

Screen printing is a popular method for creating high-quality prints on various surfaces, including fabric, paper, and more. While screen printing can be a versatile and effective way to produce designs, printing multi-layer designs with a small screen printing machine can present some challenges. However, with the right techniques and tips, you can achieve professional-looking results with your small screen printing machine.

One of the key considerations when printing multi-layer designs with a small screen printing machine is the size of the design itself. Small screen printing machines typically have limited space for larger designs, so it’s important to carefully plan and scale your design to fit within the constraints of your machine. Consider breaking down your design into smaller components or layers that can be printed separately and then combined to create the final design.

When printing multi-layer designs, it’s essential to use registration marks to ensure that each layer lines up correctly. Registration marks are small, precise marks that are printed on each layer of the design and serve as a guide for aligning the layers accurately. By carefully lining up the registration marks on each layer, you can ensure that your final print is crisp and well-aligned.

Another important tip for printing multi-layer designs with a small screen printing machine is to use a good quality ink that is suitable for the material you are printing on. Different inks are designed for use on specific surfaces, so be sure to choose an ink that is compatible with the material you are working with. Additionally, consider using opaque inks for better coverage and vibrant colors in your multi-layer designs.

In addition to using the right ink, it’s also crucial to properly cure each layer of your design to ensure that the ink sets and adheres to the material. Curing can be done using a heat press or a conveyor dryer, depending on the size and complexity of your design. Be sure to follow the manufacturer’s instructions for curing times and temperatures to achieve the best results.

When printing multi-layer designs with a small screen printing machine, it’s important to work methodically and carefully to avoid mistakes. Take your time to set up each layer of the design properly, aligning registration marks and ensuring that each layer is printed accurately. By working slowly and attentively, you can achieve professional-looking results with your small screen printing machine.

In conclusion, printing multi-layer designs with a small screen printing machine can be a challenging but rewarding process. By carefully planning your design, using registration marks, choosing the right ink, and properly curing each layer, you can achieve high-quality prints with your small screen printing machine. With practice and attention to detail, you can create stunning multi-layer designs that showcase your creativity and skill as a screen printer.

Pre: Essential Features of a High-Quality Tabletop Screen Printing Press

Next: Understanding Mesh Count in Silk Screen Printing Machines

Tags: