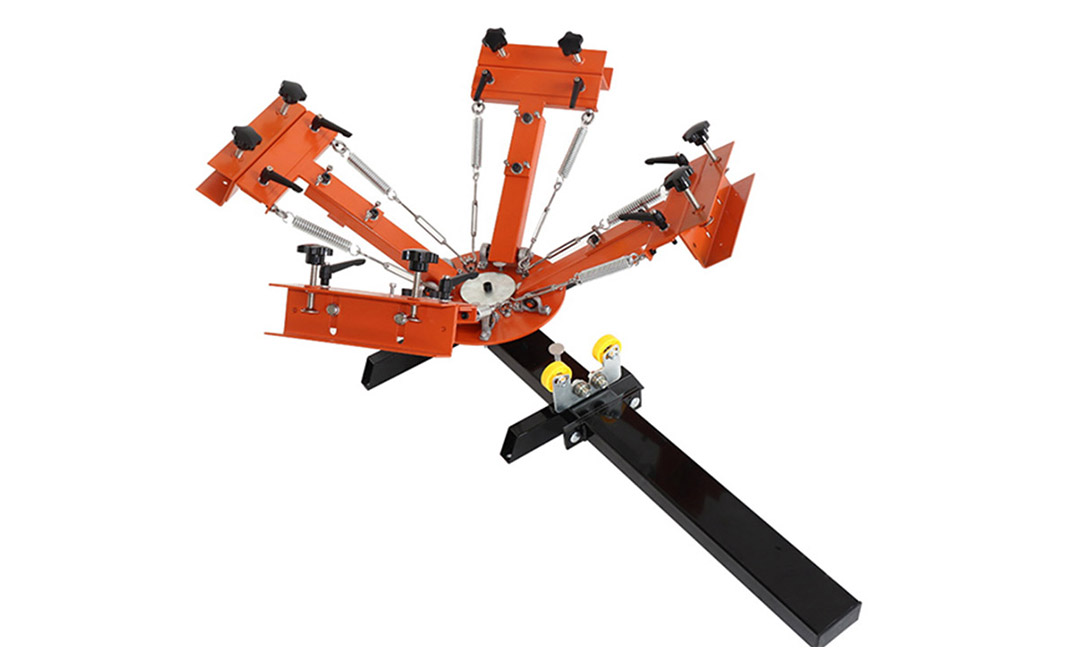

How to Maintain Your Riley Hopkins 150 1 Color 1 Station Machine

Proper Cleaning Techniques for Your Riley Hopkins 150

Maintaining your Riley Hopkins 150 1 Color 1 Station Machine is essential to ensure its longevity and optimal performance. Proper cleaning techniques are crucial in keeping your machine in top condition. In this article, we will discuss the steps you need to take to maintain your Riley Hopkins 150 effectively.

First and foremost, it is important to clean your machine regularly. Dust, dirt, and ink can build up over time, causing the machine to malfunction. To prevent this, make sure to wipe down the machine after each use with a clean, damp cloth. Pay special attention to the areas where ink tends to accumulate, such as the screen and squeegee.

In addition to regular cleaning, it is also important to deep clean your machine periodically. This involves disassembling the machine and cleaning each component thoroughly. Start by removing the screen and squeegee, then clean them with a mild detergent and water. Make sure to dry them completely before reassembling the machine.

Next, clean the frame and base of the machine with a damp cloth. Pay attention to any crevices or corners where dirt may be hiding. You can also use a mild detergent for stubborn stains. Once the machine is clean, reassemble it carefully, making sure all components are properly aligned.

Another important aspect of maintaining your Riley Hopkins 150 is lubrication. The moving parts of the machine, such as the hinges and bolts, should be lubricated regularly to prevent wear and tear. Use a silicone-based lubricant for best results. Apply a small amount to each moving part and wipe off any excess to prevent buildup.

In addition to cleaning and lubrication, it is important to inspect your machine regularly for any signs of damage or wear. Check the hinges, bolts, and other components for any loose or missing parts. If you notice any issues, address them immediately to prevent further damage to the machine.

Proper storage is also key to maintaining your Riley Hopkins 150. Store the machine in a clean, dry area away from direct sunlight and moisture. Cover the machine with a protective cover when not in use to prevent dust and dirt from accumulating.

Lastly, it is important to follow the manufacturer’s guidelines for maintenance and care. The Riley Hopkins 150 comes with a manual that outlines the recommended cleaning and maintenance procedures. Make sure to read and follow these instructions carefully to ensure the longevity of your machine.

In conclusion, maintaining your Riley Hopkins 150 1 Color 1 Station Machine is essential to ensure its optimal performance and longevity. By following the proper cleaning techniques outlined in this article, you can keep your machine in top condition for years to come. Regular cleaning, lubrication, inspection, and proper storage are key to maintaining your machine effectively. Remember to follow the manufacturer’s guidelines for maintenance and care to keep your Riley Hopkins 150 running smoothly.

Regular Maintenance Schedule for Your Riley Hopkins 150

Maintaining your Riley Hopkins 150 1 Color 1 Station Machine is essential to ensure its longevity and optimal performance. Regular maintenance not only extends the life of your machine but also helps prevent costly repairs down the line. In this article, we will discuss the importance of a regular maintenance schedule for your Riley Hopkins 150 and provide some tips on how to keep your machine in top condition.

One of the most important aspects of maintaining your Riley Hopkins 150 is keeping it clean. Dust, dirt, and ink residue can build up on the machine over time, causing it to operate less efficiently. Regularly wiping down the machine with a damp cloth and cleaning the screens and squeegees after each use can help prevent buildup and keep your machine running smoothly.

In addition to keeping your machine clean, it is also important to regularly inspect and replace any worn or damaged parts. Check the tension of the screen and make sure it is properly aligned. Inspect the squeegee and replace it if it shows signs of wear. Keeping an eye on these parts and replacing them as needed can help prevent more serious issues from arising.

Another important aspect of maintaining your Riley Hopkins 150 is lubrication. Proper lubrication of the moving parts of the machine can help reduce friction and wear, extending the life of the machine. Be sure to use a high-quality lubricant and follow the manufacturer’s recommendations for lubrication intervals.

Regularly calibrating your machine is also important for maintaining its performance. Calibration ensures that the machine is printing accurately and consistently. Follow the manufacturer’s guidelines for calibration and make any necessary adjustments to ensure that your prints are of the highest quality.

In addition to these regular maintenance tasks, it is also important to keep up with any software updates for your Riley Hopkins 150. Software updates can improve the performance and functionality of your machine, so be sure to check for updates regularly and install them as needed.

By following a regular maintenance schedule for your Riley Hopkins 150, you can ensure that your machine continues to operate at its best. Keeping your machine clean, inspecting and replacing worn parts, lubricating moving parts, calibrating the machine, and keeping up with software updates are all important aspects of maintaining your machine.

In conclusion, regular maintenance is key to keeping your Riley Hopkins 150 1 Color 1 Station Machine in top condition. By following a regular maintenance schedule and taking care of your machine, you can extend its life and ensure that it continues to produce high-quality prints. Remember to keep your machine clean, inspect and replace worn parts, lubricate moving parts, calibrate the machine, and keep up with software updates to keep your Riley Hopkins 150 running smoothly.

Troubleshooting Common Issues with Your Riley Hopkins 150

Maintaining your Riley Hopkins 150 1 Color 1 Station Machine is essential to ensure its longevity and optimal performance. Regular maintenance can help prevent common issues that may arise with the machine, saving you time and money in the long run. In this article, we will discuss some tips on how to properly maintain your Riley Hopkins 150 and troubleshoot common issues that may occur.

One of the most important aspects of maintaining your Riley Hopkins 150 is keeping it clean. Regularly cleaning the machine, including the pallets, screens, and frame, can help prevent ink buildup and ensure smooth operation. Use a mild detergent and water to clean the machine, and be sure to dry it thoroughly before using it again.

Another important maintenance tip is to regularly check and tighten any loose bolts or screws on the machine. Over time, vibrations from the machine’s operation can cause bolts and screws to become loose, which can affect the machine’s performance. By regularly checking and tightening these fasteners, you can prevent issues such as misalignment or shifting of the machine.

It is also important to regularly lubricate the moving parts of the machine to ensure smooth operation. Use a high-quality lubricant to grease the bearings, hinges, and other moving parts of the machine. This will help reduce friction and wear on the parts, prolonging the life of the machine.

In addition to regular maintenance, it is important to troubleshoot any issues that may arise with your Riley Hopkins 150. One common issue that users may encounter is misalignment of the screen or pallets. If you notice that the screen or pallets are not aligned properly, you can adjust them using the adjustment knobs on the machine. Be sure to follow the manufacturer’s instructions for proper alignment to avoid damaging the machine.

Another common issue that users may encounter is ink buildup on the screen or pallets. If you notice ink buildup, you can clean the affected areas using a mild solvent or cleaner. Be sure to follow the manufacturer’s instructions for cleaning to avoid damaging the machine or voiding the warranty.

If you are experiencing issues with the machine’s registration or print quality, it may be due to improper tension on the screen or pallets. You can adjust the tension using the tension knobs on the machine to achieve the desired results. Be sure to test the machine after making adjustments to ensure that the issue has been resolved.

If you are unable to troubleshoot and resolve the issue on your own, it may be necessary to contact the manufacturer or a professional technician for assistance. They can help diagnose the issue and provide guidance on how to resolve it effectively.

In conclusion, maintaining your Riley Hopkins 150 1 Color 1 Station Machine is essential to ensure its optimal performance and longevity. By following these tips on proper maintenance and troubleshooting common issues, you can keep your machine running smoothly and avoid costly repairs. Remember to regularly clean, lubricate, and check the machine for any loose bolts or screws to prevent issues from arising. If you encounter any issues that you are unable to resolve on your own, do not hesitate to seek professional assistance.

Pre: Step-by-Step Installation of Riley Hopkins 150 4 Color 1 Station

Next: Troubleshooting Common Issues with Vevor 4 Color 1 Station Machine

Tags: