How to Keep Your Manual Screen Printing Press in Optimal Condition

Regular Cleaning and Maintenance Routine

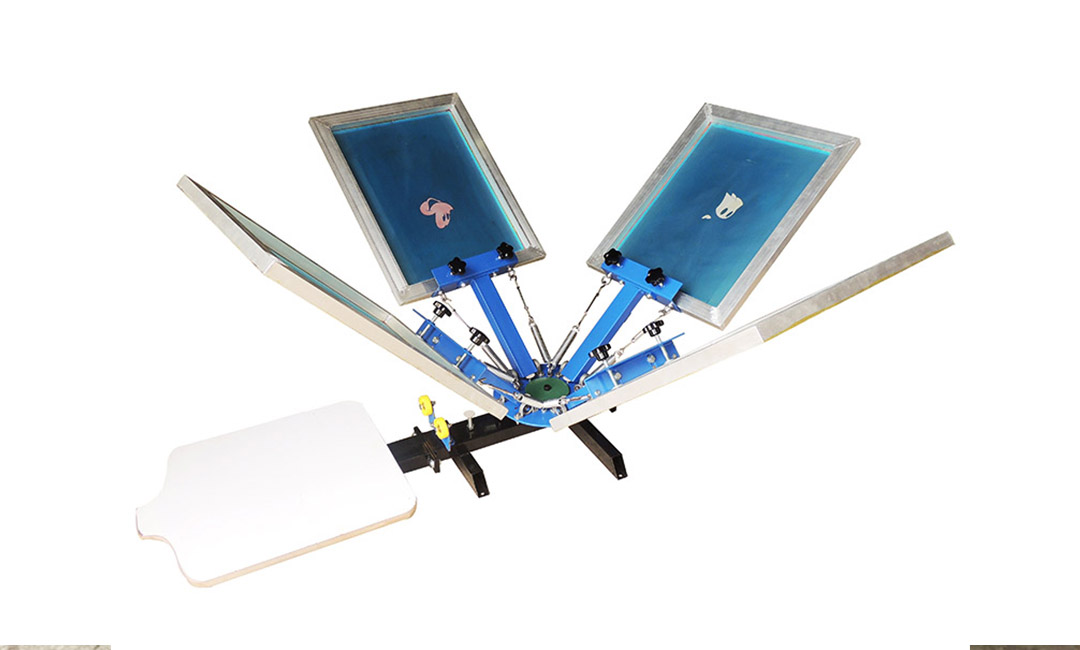

Manual screen printing presses are essential tools for any screen printing business. To ensure that your press continues to operate efficiently and produce high-quality prints, it is important to establish a regular cleaning and maintenance routine. By following these simple steps, you can keep your manual screen printing press in optimal condition and extend its lifespan.

One of the most important aspects of maintaining a manual screen printing press is keeping it clean. Dust, ink, and debris can build up on the press over time, leading to poor print quality and potential damage to the machine. To prevent this, it is recommended to clean the press after each use. Start by wiping down the entire press with a damp cloth to remove any excess ink or debris. Pay special attention to the screen, squeegee, and pallets, as these are the areas that come into direct contact with the ink.

In addition to regular cleaning, it is also important to lubricate the moving parts of the press to ensure smooth operation. Apply a small amount of lubricant to the hinges, bolts, and other moving components of the press to prevent friction and wear. Be sure to use a lubricant that is compatible with the materials used in your press to avoid damage.

Another important aspect of maintaining a manual screen printing press is checking for any loose or damaged parts. Inspect the press regularly for loose bolts, screws, or other components that may need tightening or replacement. If you notice any damaged parts, such as a cracked screen or a worn squeegee, be sure to replace them promptly to prevent further damage to the press.

In addition to regular cleaning and maintenance, it is also important to store your manual screen printing press properly when not in use. Store the press in a clean, dry area away from direct sunlight and moisture to prevent rust and corrosion. Cover the press with a protective cover or tarp to keep dust and debris from accumulating on the machine.

By establishing a regular cleaning and maintenance routine for your manual screen printing press, you can ensure that it continues to operate efficiently and produce high-quality prints. Taking the time to clean, lubricate, and inspect your press regularly can help prevent costly repairs and downtime in the future. With proper care and maintenance, your manual screen printing press can continue to be a valuable asset to your screen printing business for years to come.

Proper Lubrication of Moving Parts

Manual screen printing presses are essential tools for any screen printing business. To ensure that your press operates smoothly and efficiently, proper maintenance is crucial. One key aspect of maintaining a manual screen printing press is ensuring that all moving parts are properly lubricated. In this article, we will discuss the importance of lubricating your press and provide some tips on how to do so effectively.

Lubrication is essential for keeping your manual screen printing press in optimal condition. Without proper lubrication, moving parts can become stiff and difficult to operate, leading to increased wear and tear on the press. This can result in decreased print quality and potentially costly repairs. By regularly lubricating your press, you can extend its lifespan and ensure that it continues to perform at its best.

When it comes to lubricating your manual screen printing press, there are a few key points to keep in mind. First, it is important to use the right type of lubricant. Not all lubricants are suitable for use on printing presses, so be sure to choose a lubricant that is specifically designed for use on machinery. Silicone-based lubricants are a popular choice for screen printing presses, as they provide excellent lubrication without leaving behind any residue that could affect print quality.

Before applying lubricant to your press, it is important to clean the moving parts thoroughly. Dirt and debris can accumulate on the press over time, causing friction and wear on the moving parts. Use a mild detergent and water to clean the press, being careful to avoid getting any water on the electrical components. Once the press is clean, dry it thoroughly before applying lubricant.

When applying lubricant to your manual screen printing press, be sure to apply it sparingly. Over-lubricating can attract dirt and debris, leading to increased wear on the press. Apply a small amount of lubricant to each moving part, taking care to distribute it evenly. Be sure to follow the manufacturer’s recommendations for lubrication intervals, as over-lubricating can be just as harmful as under-lubricating.

In addition to regular lubrication, it is important to inspect your manual screen printing press regularly for signs of wear or damage. Check for loose or worn parts, and replace them as needed. Keeping your press in good working order will not only ensure that it continues to perform at its best, but will also help to prevent costly repairs down the line.

In conclusion, proper lubrication of moving parts is essential for keeping your manual screen printing press in optimal condition. By using the right type of lubricant, cleaning the press thoroughly before applying lubricant, and inspecting the press regularly for signs of wear or damage, you can extend the lifespan of your press and ensure that it continues to perform at its best. Taking the time to properly maintain your press will pay off in the long run, saving you time and money on repairs and ensuring that your prints are of the highest quality.

Inspection and Replacement of Worn Components

Manual screen printing presses are essential tools for any screen printing business. To ensure that your press continues to operate efficiently and produce high-quality prints, it is important to regularly inspect and replace worn components. By taking the time to properly maintain your press, you can extend its lifespan and avoid costly repairs down the line.

One of the first steps in maintaining your manual screen printing press is to conduct a thorough inspection of all its components. This includes checking the frame, pallets, arms, and springs for any signs of wear or damage. Look for cracks, dents, or rust that could affect the press’s performance. It is also important to inspect the bolts and screws that hold the press together, as loose or missing fasteners can lead to instability and misalignment.

If you notice any worn or damaged components during your inspection, it is crucial to replace them as soon as possible. Neglecting to replace worn parts can result in poor print quality, registration issues, and even damage to the press itself. When replacing components, be sure to use high-quality replacement parts that are designed specifically for your press model. This will help ensure proper fit and function, and prevent further damage to the press.

In addition to inspecting and replacing worn components, it is important to regularly clean and lubricate your manual screen printing press. Dust, ink, and debris can build up on the press over time, causing it to operate less efficiently. Use a soft brush or cloth to remove any buildup from the frame, pallets, and arms. Be sure to also clean the screen clamps and hinges, as these areas can become clogged with ink and debris.

After cleaning the press, apply a small amount of lubricant to the moving parts to keep them operating smoothly. Be sure to use a lubricant that is compatible with the materials used in your press, as some lubricants can cause damage to certain components. Regularly lubricating your press will help prevent friction and wear, and ensure that it continues to operate at its best.

In addition to regular maintenance, it is important to store your manual screen printing press properly when not in use. Keep the press covered with a protective tarp or sheet to prevent dust and debris from accumulating on its surfaces. Store the press in a dry, climate-controlled environment to prevent rust and corrosion. If possible, disassemble the press and store it in separate pieces to prevent damage during storage.

By following these tips for inspecting and replacing worn components, cleaning and lubricating your press, and storing it properly, you can keep your manual screen printing press in optimal condition for years to come. Regular maintenance will not only extend the lifespan of your press but also ensure that it continues to produce high-quality prints for your business. Take the time to care for your press, and it will reward you with reliable performance and consistent results.

Pre: The Best T-Shirt Screen Printing Equipment for Your Business

Next: What to Know About 4 Color Screen Printers for Custom Apparel

Tags: