How to Get the Most Out of Your Single Platen Screen Printer

Proper Maintenance Techniques for Single Platen Screen Printers

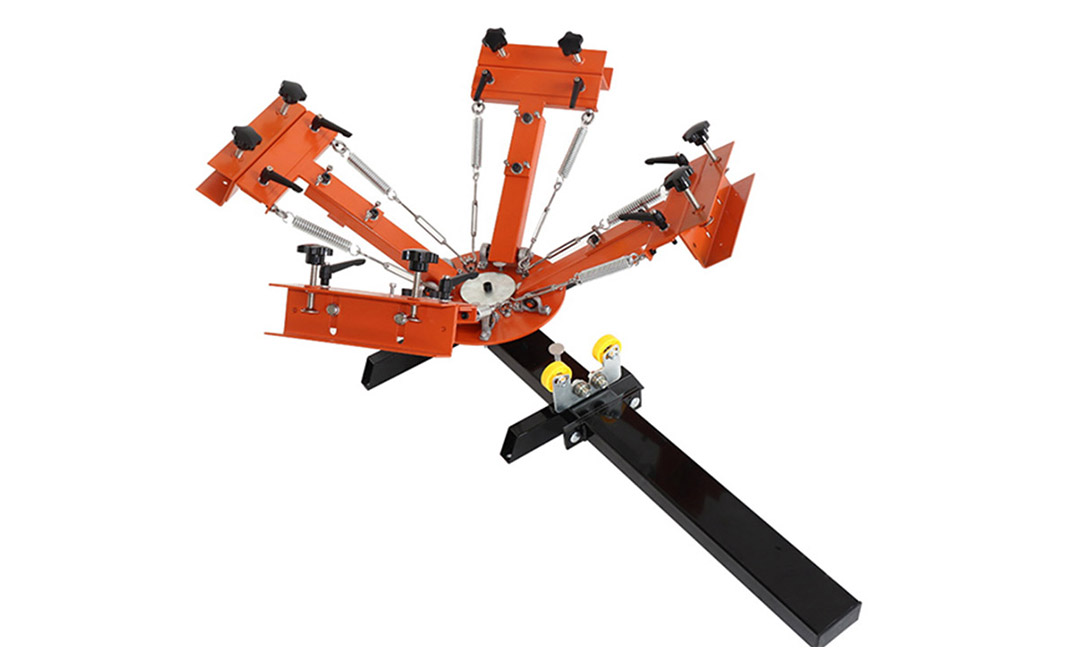

Screen printing is a popular method of printing that involves transferring ink onto a substrate through a mesh screen. Single platen screen printers are commonly used in small to medium-sized printing businesses, as they are versatile and easy to use. To ensure that your single platen screen printer operates efficiently and produces high-quality prints, proper maintenance is essential.

One of the most important maintenance tasks for a single platen screen printer is keeping the screen clean. Over time, ink residue can build up on the screen, causing it to become clogged and affecting the quality of the prints. To prevent this, it is important to regularly clean the screen with a mild detergent and water. Avoid using harsh chemicals or abrasive materials, as these can damage the screen and affect its performance.

In addition to keeping the screen clean, it is also important to regularly check and replace the squeegee and flood bar on your single platen screen printer. These components play a crucial role in transferring ink onto the substrate and ensuring even coverage. If the squeegee or flood bar becomes worn or damaged, it can affect the quality of the prints and lead to uneven ink distribution. By regularly inspecting and replacing these components, you can ensure that your single platen screen printer continues to produce high-quality prints.

Another important maintenance task for single platen screen printers is checking and adjusting the tension of the screen. The tension of the screen affects the quality of the prints and can impact the registration of the design. If the screen tension is too loose, it can lead to blurry or distorted prints, while if it is too tight, it can cause the screen to break or tear. By regularly checking and adjusting the screen tension, you can ensure that your single platen screen printer produces crisp, clear prints every time.

In addition to these maintenance tasks, it is also important to regularly lubricate the moving parts of your single platen screen printer. This includes the hinges, bearings, and other components that allow the printer to operate smoothly. By keeping these parts well-lubricated, you can prevent wear and tear and extend the life of your printer.

Finally, it is important to store your single platen screen printer properly when not in use. This includes covering the printer to protect it from dust and debris, as well as storing it in a clean, dry environment. By taking these steps, you can ensure that your single platen screen printer remains in good working condition and continues to produce high-quality prints for years to come.

In conclusion, proper maintenance is essential for getting the most out of your single platen screen printer. By keeping the screen clean, checking and replacing the squeegee and flood bar, adjusting the screen tension, lubricating moving parts, and storing the printer properly, you can ensure that your printer operates efficiently and produces high-quality prints. By following these maintenance techniques, you can extend the life of your single platen screen printer and maximize its performance.

Maximizing Efficiency and Productivity with Single Platen Screen Printers

Screen printing is a popular method of printing that involves using a mesh screen to transfer ink onto a substrate, such as a t-shirt or poster. Single platen screen printers are a common type of screen printing machine that is used by many businesses and individuals. These machines have a single printing surface, or platen, which makes them ideal for printing on smaller items or for smaller production runs.

To get the most out of your single platen screen printer, there are a few key tips and tricks to keep in mind. First and foremost, it is important to properly set up and calibrate your machine. This includes ensuring that the screen is properly tensioned, the squeegee is at the correct angle, and the ink is properly mixed and applied. Taking the time to properly set up your machine will help ensure that you get the best possible results from your prints.

Another important factor to consider when using a single platen screen printer is the type of ink you are using. Different types of ink are designed for different substrates, so it is important to choose the right ink for the job. Additionally, some inks require special curing methods, such as heat curing or air drying, so be sure to follow the manufacturer’s instructions for best results.

In addition to proper setup and ink selection, it is also important to consider the design and placement of your prints. When using a single platen screen printer, you are limited to printing on a single surface at a time, so it is important to carefully plan out your designs and placement to maximize efficiency. Consider using registration marks or guides to ensure that your prints are aligned correctly and consistently.

One of the key benefits of using a single platen screen printer is its versatility. These machines are capable of printing on a wide range of substrates, including t-shirts, posters, and other promotional items. By taking advantage of this versatility, you can maximize the efficiency and productivity of your machine. Consider offering a variety of products and services to your customers to make the most of your single platen screen printer.

Finally, it is important to regularly maintain and clean your single platen screen printer to ensure optimal performance. This includes regularly cleaning the screen, squeegee, and ink trays, as well as checking for any signs of wear or damage. By taking the time to properly maintain your machine, you can extend its lifespan and ensure that it continues to produce high-quality prints for years to come.

In conclusion, getting the most out of your single platen screen printer requires careful planning, proper setup, and regular maintenance. By following these tips and tricks, you can maximize the efficiency and productivity of your machine and produce high-quality prints for your customers. Whether you are a small business owner or a hobbyist, a single platen screen printer can be a valuable tool for creating custom prints and promotional items.

Tips for Achieving High-Quality Prints with Single Platen Screen Printers

Screen printing is a popular method of printing that involves transferring ink onto a substrate through a mesh screen. Single platen screen printers are a common type of screen printing machine that is used for printing on various materials such as t-shirts, posters, and other promotional items. To achieve high-quality prints with a single platen screen printer, there are several tips and techniques that you can follow.

First and foremost, it is important to properly prepare your artwork before printing. Make sure that your design is clean, crisp, and high resolution to ensure that it will transfer well onto the substrate. Additionally, make sure that your artwork is properly sized and positioned on the screen to avoid any misalignment issues during printing.

When setting up your single platen screen printer, make sure that the screen is properly tensioned and aligned with the platen. This will help to ensure that your prints come out sharp and clear. Additionally, make sure that the ink is properly mixed and applied to the screen in a consistent manner to avoid any blotchy or uneven prints.

Another important tip for achieving high-quality prints with a single platen screen printer is to use the right type of ink for the material that you are printing on. Different inks are designed for different substrates, so make sure that you are using the correct ink for the job. Additionally, make sure that you are using the right mesh count for your screen to ensure that the ink is properly transferred onto the substrate.

When printing with a single platen screen printer, it is important to pay attention to the printing speed and pressure. Printing too quickly or with too much pressure can result in smudged or blurry prints, while printing too slowly or with too little pressure can result in uneven prints. Experiment with different printing speeds and pressures to find the right balance for your specific job.

In addition to proper printing techniques, it is also important to properly cure your prints after they have been printed. Curing the prints involves applying heat to the printed substrate to help the ink bond with the material. Make sure that you are using the right temperature and curing time for the type of ink that you are using to ensure that your prints are durable and long-lasting.

Finally, it is important to properly clean and maintain your single platen screen printer to ensure that it continues to produce high-quality prints. Regularly clean the screen, platen, and other components of the printer to remove any ink buildup or debris that could affect the quality of your prints. Additionally, make sure to regularly check and replace any worn or damaged parts to keep your printer running smoothly.

In conclusion, achieving high-quality prints with a single platen screen printer requires attention to detail, proper preparation, and the right techniques. By following these tips and techniques, you can ensure that your prints come out sharp, clear, and professional-looking every time. With practice and patience, you can master the art of screen printing and create stunning prints that will impress your customers and clients.

Pre: How to Choose a Compact Screen Printing Press for Small Spaces

Next: The Top Screen Printing Inks for Every Type of Printing Project

Tags: