How to Find High-Quality Used Screen Printing Machines

Researching Reputable Sellers

When embarking on the journey to find high-quality used screen printing machines, one of the most critical steps is researching reputable sellers. This process not only ensures that you acquire a machine that meets your operational needs but also safeguards your investment against potential pitfalls associated with purchasing used equipment. To begin with, it is essential to identify sellers who have established a solid reputation in the industry. This can be achieved by seeking recommendations from fellow screen printing professionals, as their firsthand experiences can provide valuable insights into the reliability of various sellers.

In addition to personal recommendations, online reviews and testimonials serve as a crucial resource for evaluating the credibility of potential sellers. Websites dedicated to equipment sales often feature customer feedback, which can highlight both the strengths and weaknesses of a seller’s offerings. By carefully analyzing these reviews, you can gain a clearer understanding of the seller’s customer service, the quality of their machines, and their overall business practices. Furthermore, it is advisable to check for any complaints filed against the seller with consumer protection agencies or industry associations, as this information can reveal patterns of behavior that may be concerning.

Once you have narrowed down your list of potential sellers, it is prudent to investigate their business history. A seller with a long-standing presence in the market is often more reliable than a newcomer, as longevity typically indicates a commitment to quality and customer satisfaction. Additionally, consider whether the seller specializes in screen printing equipment or if they offer a broader range of machinery. Specialized sellers are more likely to have a deeper understanding of the specific needs and challenges associated with screen printing, which can be beneficial when seeking advice or support.

Moreover, engaging directly with sellers can provide further clarity regarding their operations. Initiating a conversation, whether through email or phone, allows you to gauge their responsiveness and willingness to address your inquiries. A reputable seller should be open to discussing the condition of their machines, providing detailed information about maintenance history, and offering insights into the machine’s performance. This level of transparency is a strong indicator of a seller’s integrity and commitment to customer satisfaction.

In addition to direct communication, it is also wise to inquire about any warranties or guarantees associated with the used machines. A seller who stands behind their products will often provide some form of warranty, which can offer peace of mind and protection against unforeseen issues. This aspect is particularly important when purchasing used equipment, as it can mitigate the risks associated with potential defects or malfunctions.

Furthermore, attending industry trade shows or local equipment expos can be an excellent way to connect with reputable sellers in person. These events often feature a variety of vendors showcasing their machines, allowing you to inspect the equipment firsthand and ask questions directly. This face-to-face interaction can foster a sense of trust and provide an opportunity to build relationships with sellers who may offer ongoing support and resources.

In conclusion, researching reputable sellers is a fundamental step in the process of acquiring high-quality used screen printing machines. By leveraging personal recommendations, online reviews, and direct communication, you can identify trustworthy sellers who prioritize customer satisfaction. Additionally, considering warranties and attending industry events can further enhance your search, ultimately leading to a successful purchase that meets your screen printing needs.

Evaluating Machine Condition

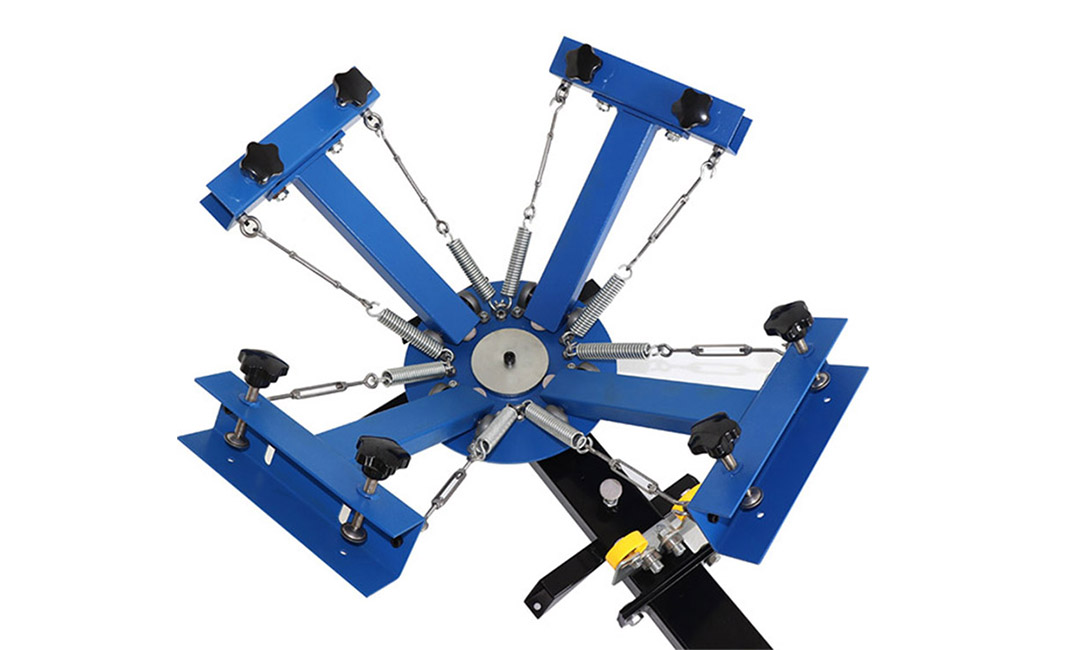

When considering the purchase of a used screen printing machine, evaluating the machine’s condition is paramount to ensuring a wise investment. The first step in this process involves a thorough visual inspection. Begin by examining the exterior of the machine for any signs of wear and tear, such as rust, dents, or corrosion. These indicators can provide insight into how well the machine has been maintained and whether it has been subjected to harsh working conditions. Additionally, check for any missing parts or components, as this could affect the machine’s functionality and lead to costly repairs down the line.

Once the exterior has been assessed, it is essential to delve deeper into the machine’s operational components. This includes inspecting the print heads, squeegees, and flood bars for any signs of damage or excessive wear. A well-maintained print head should be free of scratches and should move smoothly without any obstruction. If the print heads show signs of wear, it may indicate that the machine has been heavily used, which could compromise print quality. Furthermore, ensure that the squeegees are in good condition, as worn squeegees can lead to inconsistent ink application and ultimately affect the final product.

In addition to the physical components, it is crucial to evaluate the machine’s mechanical and electrical systems. Start by checking the machine’s motor and drive system for any unusual noises or vibrations during operation. A well-functioning motor should operate quietly and smoothly. If possible, request a demonstration of the machine in action, as this will allow you to observe its performance firsthand. Pay attention to the speed and consistency of the printing process, as any irregularities may signal underlying issues that could require significant repairs.

Moreover, it is advisable to inquire about the machine’s maintenance history. A well-documented maintenance record can provide valuable insights into how the machine has been cared for over the years. Ask the seller about any repairs that have been made, as well as the frequency of routine maintenance checks. Machines that have been regularly serviced are likely to be in better condition than those that have been neglected. Additionally, understanding the age of the machine can help you gauge its remaining lifespan and potential for future repairs.

Another important aspect to consider is the availability of replacement parts. As screen printing machines age, certain components may become obsolete or harder to find. Before finalizing your purchase, research the availability of parts for the specific model you are considering. This will not only help you assess the long-term viability of the machine but also ensure that you can easily source replacements if needed.

Finally, it is wise to consult with industry professionals or experienced screen printers who can offer insights into the specific model you are evaluating. Their expertise can provide valuable context regarding the machine’s reputation, reliability, and common issues associated with that particular model. By gathering information from multiple sources, you can make a more informed decision and increase your chances of acquiring a high-quality used screen printing machine that meets your operational needs. In conclusion, a meticulous evaluation of the machine’s condition, combined with thorough research and expert advice, will empower you to make a sound investment in your screen printing endeavors.

Understanding Pricing and Value

When embarking on the journey to find high-quality used screen printing machines, understanding pricing and value is paramount. The market for used equipment can be both vast and varied, making it essential for potential buyers to grasp the nuances that influence pricing. Initially, it is important to recognize that the value of a used screen printing machine is not solely determined by its age or brand but also by its condition, features, and the demand within the industry.

To begin with, assessing the condition of a used machine is crucial. Machines that have been well-maintained and serviced regularly will typically command higher prices than those that show signs of wear and tear. Therefore, it is advisable to inquire about the machine’s maintenance history, including any repairs or upgrades that have been performed. Additionally, inspecting the machine in person, if possible, allows buyers to evaluate its physical state, ensuring that they are making a sound investment.

Moreover, the features of the machine play a significant role in determining its value. Advanced models equipped with modern technology, such as automatic registration systems or enhanced ink delivery mechanisms, may be priced higher due to their efficiency and productivity. Conversely, older models lacking these features may be more affordable but could result in higher operational costs over time. Consequently, buyers should weigh the benefits of investing in a more expensive, feature-rich machine against the potential savings of a lower-priced option.

In addition to condition and features, market demand significantly influences pricing. The screen printing industry is subject to trends, and certain types of machines may become more sought after due to shifts in consumer preferences or advancements in printing technology. For instance, as eco-friendly practices gain traction, machines that support water-based inks may see an increase in demand, thereby affecting their market value. Therefore, staying informed about industry trends can provide valuable insights into which machines may offer the best return on investment.

Furthermore, it is essential to consider the source from which the machine is purchased. Buying from reputable dealers or established manufacturers can provide a level of assurance regarding the quality and reliability of the equipment. These sources often offer warranties or guarantees, which can mitigate the risks associated with purchasing used machinery. On the other hand, private sellers may offer lower prices, but they often lack the same level of accountability. Thus, conducting thorough research on the seller’s reputation can be instrumental in ensuring a satisfactory purchase.

As buyers navigate the used screen printing machine market, it is also beneficial to compare prices across different platforms. Online marketplaces, auction sites, and industry-specific forums can provide a wealth of information regarding current pricing trends. By gathering data from multiple sources, buyers can develop a clearer understanding of what constitutes a fair price for the machine they are considering.

Ultimately, finding high-quality used screen printing machines requires a comprehensive understanding of pricing and value. By evaluating the condition, features, and market demand, as well as considering the source of purchase and conducting thorough price comparisons, buyers can make informed decisions that align with their operational needs and budget constraints. This careful approach not only enhances the likelihood of acquiring a reliable machine but also contributes to the overall success of the screen printing business.

Pre: Finding the Best Affordable Screen Printing Machines for Your Budget

Next: How to Create the Perfect Screen Printing Startup Package for Success

Tags: