How to Choose the Right Screen Printing Frame Clamps for Your Press

Proper Size and Compatibility

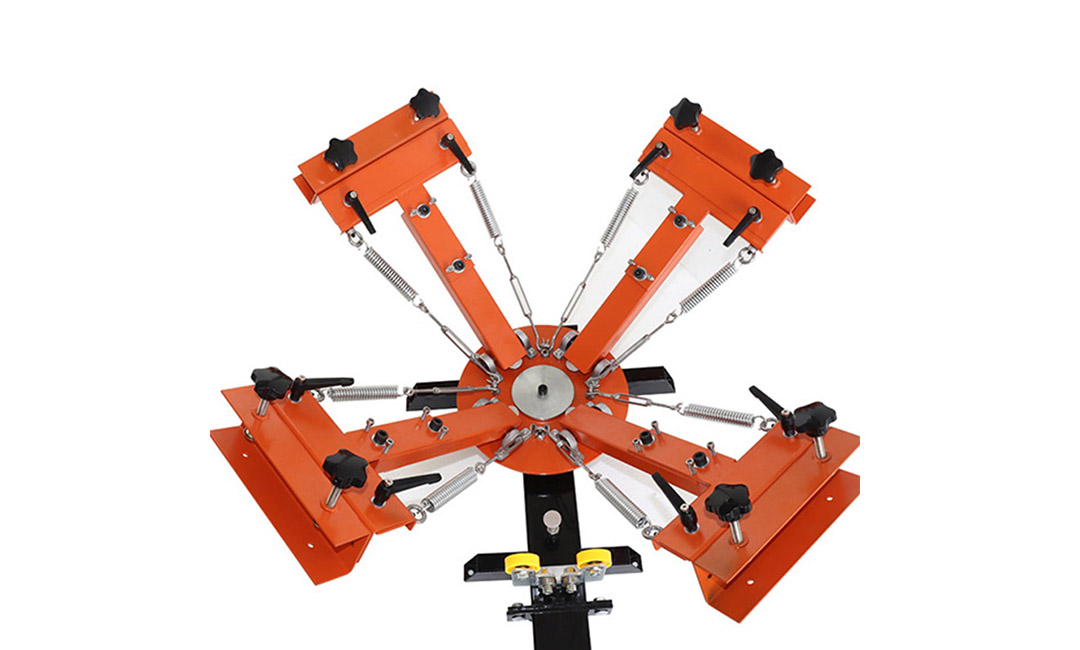

Screen printing frame clamps are an essential component of any screen printing press. They are used to secure the screen frame in place during the printing process, ensuring that the screen remains stable and in the correct position. Choosing the right screen printing frame clamps for your press is crucial to achieving high-quality prints and maximizing efficiency in your printing operation.

One of the most important factors to consider when selecting screen printing frame clamps is the size of the clamps. The size of the clamps should be compatible with the size of the screen frame that you will be using. If the clamps are too small, they may not be able to securely hold the frame in place, leading to shifting or movement during printing. On the other hand, if the clamps are too large, they may not be able to properly grip the frame, resulting in instability and potential printing errors.

When choosing screen printing frame clamps, it is important to consider the dimensions of your screen frame, including the width and thickness of the frame. Measure the width of the frame at its widest point and the thickness of the frame at its thickest point to ensure that the clamps you choose will be able to securely hold the frame in place. Additionally, consider the overall size of the frame and the amount of surface area that the clamps will need to cover to provide adequate support.

In addition to size, it is also important to consider the compatibility of the clamps with your screen printing press. Different presses may have different mounting systems or configurations, so it is important to choose clamps that are designed to work with your specific press. Some clamps may be designed for use with specific press models or brands, so be sure to check the compatibility of the clamps with your press before making a purchase.

Another factor to consider when choosing screen printing frame clamps is the material from which they are made. Clamps are typically made from metal or plastic, with metal clamps being more durable and long-lasting, while plastic clamps may be more affordable and lightweight. Consider the level of use and wear and tear that your clamps will be subjected to when choosing the material. If you will be using your press frequently or for high-volume printing, investing in metal clamps may be a wise choice to ensure longevity and durability.

When selecting screen printing frame clamps, it is also important to consider the ease of use and adjustability of the clamps. Look for clamps that are easy to install and adjust, allowing you to quickly and easily secure the frame in place and make any necessary adjustments during the printing process. Some clamps may feature quick-release mechanisms or adjustable tension settings, making them more versatile and user-friendly.

In conclusion, choosing the right screen printing frame clamps for your press is essential to achieving high-quality prints and maximizing efficiency in your printing operation. Consider factors such as size, compatibility, material, and ease of use when selecting clamps to ensure that they will provide secure and stable support for your screen frame. By taking the time to carefully choose the right clamps for your press, you can ensure that your printing operation runs smoothly and produces professional results.

Material and Durability

When it comes to screen printing, having the right equipment is essential for achieving high-quality results. One crucial component of a screen printing press is the frame clamp, which holds the screen in place during the printing process. Choosing the right frame clamps for your press is important to ensure stability, accuracy, and durability.

One of the first factors to consider when selecting frame clamps is the material they are made of. Frame clamps are typically constructed from either aluminum or steel. Aluminum frame clamps are lightweight and easy to handle, making them a popular choice for smaller presses or for printers who need to frequently adjust their screens. However, aluminum frame clamps may not be as durable as steel frame clamps and may be more prone to bending or warping over time.

On the other hand, steel frame clamps are known for their strength and durability. They can withstand heavy use and provide a secure grip on the screen, ensuring that it stays in place during the printing process. Steel frame clamps are ideal for larger presses or for printers who work with thicker screens or heavier substrates. While steel frame clamps may be heavier and more cumbersome to handle than aluminum frame clamps, their durability makes them a reliable choice for long-term use.

In addition to material, it is important to consider the design of the frame clamps. Some frame clamps feature adjustable tension knobs or screws that allow you to customize the tightness of the grip on the screen. This can be useful for achieving the perfect tension for different types of screens or substrates. Other frame clamps may have quick-release mechanisms that make it easy to remove and replace screens quickly and efficiently.

When selecting frame clamps for your press, it is also important to consider the size and shape of the screens you will be using. Frame clamps come in a variety of sizes to accommodate different screen sizes, so be sure to choose frame clamps that are compatible with the screens you plan to use. Additionally, consider the shape of the frame clamps – some frame clamps are designed for use with specific types of screens, such as round or oval frames.

Finally, consider the overall quality and reputation of the manufacturer when choosing frame clamps for your press. Look for frame clamps that are made by reputable companies known for producing high-quality screen printing equipment. Reading reviews from other printers or seeking recommendations from industry professionals can help you make an informed decision.

In conclusion, selecting the right frame clamps for your screen printing press is essential for achieving consistent and professional results. Consider factors such as material, design, size, and manufacturer reputation when choosing frame clamps for your press. By investing in high-quality frame clamps that are durable, reliable, and compatible with your screens, you can ensure that your printing process runs smoothly and efficiently.

Ease of Use and Adjustability

Screen printing is a popular method of transferring designs onto various surfaces, such as t-shirts, posters, and other promotional items. One essential component of a screen printing press is the frame clamp, which holds the screen in place during the printing process. Choosing the right frame clamps for your press is crucial for achieving high-quality prints and maximizing efficiency.

When selecting frame clamps for your screen printing press, two key factors to consider are ease of use and adjustability. Frame clamps that are easy to use can save you time and frustration during the printing process. Look for clamps that can be quickly and securely tightened and released, allowing you to easily swap out screens as needed. Additionally, consider the overall design of the clamps – are they ergonomically designed for comfortable use over long periods of time?

Adjustability is another important factor to consider when choosing frame clamps for your press. The ability to adjust the tension of the clamps ensures that the screen is held securely in place without causing damage to the frame or the mesh. Look for clamps that offer a wide range of adjustment options, allowing you to fine-tune the tension to suit different types of screens and printing applications. Some frame clamps even come with built-in tension meters, making it easy to achieve consistent results with each print.

When shopping for frame clamps, be sure to consider the size and type of screens you will be using with your press. Frame clamps come in a variety of sizes to accommodate different screen sizes, so be sure to choose clamps that are compatible with the screens you plan to use. Additionally, consider the material of the clamps – metal clamps are durable and long-lasting, while plastic clamps may be more affordable but may not offer the same level of durability.

It is also important to consider the overall design of the frame clamps. Some clamps feature a quick-release mechanism that allows you to easily remove and replace screens, while others may require more manual adjustment. Consider your workflow and printing needs when choosing frame clamps – if you frequently switch between different screens or designs, a quick-release clamp may be the best option for you.

Finally, consider the reputation of the manufacturer when choosing frame clamps for your press. Look for reputable brands that are known for producing high-quality, reliable products. Reading reviews from other screen printers can also help you make an informed decision about which frame clamps are best for your press.

In conclusion, choosing the right frame clamps for your screen printing press is essential for achieving high-quality prints and maximizing efficiency. Consider factors such as ease of use, adjustability, compatibility with your screens, and overall design when selecting frame clamps. By taking the time to research and choose the best frame clamps for your press, you can ensure that your screen printing operation runs smoothly and produces professional results.

Pre: Choosing the Best Compact Screen Printing Equipment for Small Operations

Next: How to Choose the Best Screen Printing Press for Your Small Business

Tags: