How to Choose the Best Professional Screen Printing Machine

Key Features to Consider in a Screen Printing Machine

When selecting a professional screen printing machine, it is essential to consider several key features that can significantly impact the quality of your prints, the efficiency of your workflow, and the overall return on your investment. One of the foremost aspects to evaluate is the machine’s build quality. A robust and durable construction not only ensures longevity but also enhances stability during the printing process. Machines made from high-quality materials, such as steel or aluminum, tend to withstand the rigors of frequent use, thereby reducing the likelihood of mechanical failures that could disrupt production.

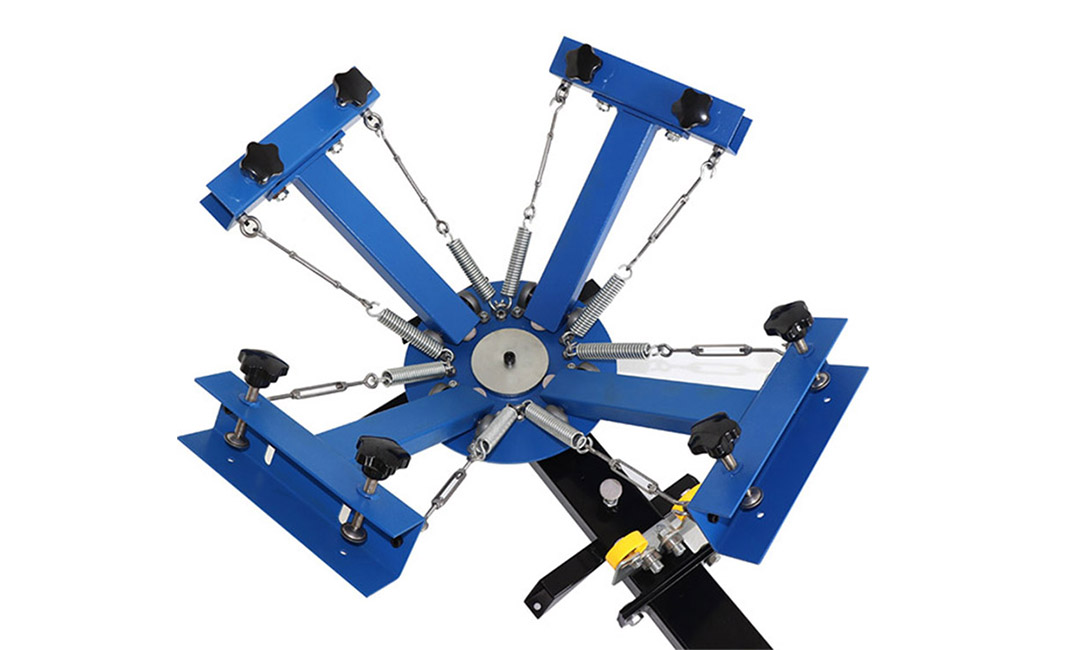

In addition to build quality, the type of screen printing machine is another critical factor. There are primarily two categories: manual and automatic machines. Manual machines are often more affordable and suitable for small-scale operations or hobbyists, while automatic machines, though more expensive, offer higher production rates and consistency, making them ideal for larger businesses. Therefore, understanding your production needs and budget constraints will guide you in choosing the right type of machine.

Furthermore, the size of the printing area is a vital consideration. A larger printing area allows for more extensive designs and the ability to print on various garment sizes, which can be particularly advantageous for businesses that cater to diverse customer needs. Conversely, a smaller printing area may limit your design capabilities and the types of products you can print on. Thus, assessing your target market and the range of products you intend to offer will help determine the appropriate size for your machine.

Another important feature to examine is the ease of use and setup. A user-friendly machine can significantly reduce the learning curve for new operators, allowing for quicker adaptation and increased productivity. Look for machines that offer intuitive controls and straightforward setup processes. Additionally, consider whether the machine includes features such as micro-registration, which allows for precise alignment of colors in multi-color prints. This feature can be particularly beneficial for achieving high-quality results and minimizing waste.

Moreover, the versatility of the machine should not be overlooked. A screen printing machine that can accommodate various substrates, such as textiles, plastics, and paper, provides greater flexibility in your printing capabilities. This versatility can open up new revenue streams and allow you to cater to a broader clientele. Therefore, it is advisable to choose a machine that can adapt to different materials and printing techniques.

In conjunction with versatility, the availability of accessories and add-ons is another aspect to consider. Some machines come with optional attachments, such as flash dryers or conveyor dryers, which can enhance your printing process and improve efficiency. Investing in a machine that offers these options can save you time and money in the long run, as you will not need to purchase additional equipment separately.

Lastly, it is crucial to evaluate the support and warranty provided by the manufacturer. A reputable company will offer comprehensive customer support, including training resources and troubleshooting assistance. Additionally, a solid warranty can provide peace of mind, ensuring that you are protected against potential defects or issues that may arise after purchase. By carefully considering these key features, you can make an informed decision when selecting the best professional screen printing machine for your business, ultimately leading to enhanced productivity and superior print quality.

Comparing Different Types of Screen Printing Machines

When it comes to selecting the best professional screen printing machine, understanding the various types available is crucial for making an informed decision. Screen printing, a versatile and widely used method for transferring designs onto various substrates, can be accomplished using different machines, each with its unique features and capabilities. By comparing these types, one can better assess which machine aligns with specific business needs and production goals.

To begin with, manual screen printing machines are often favored by small businesses and startups due to their affordability and simplicity. These machines require the operator to manually place the screens and apply the ink, which allows for a hands-on approach to the printing process. While they may not be as efficient as automated options, manual machines provide a great deal of control over the printing process, making them ideal for custom jobs and small runs. Additionally, they require less initial investment, making them accessible for those just entering the screen printing industry.

On the other hand, automatic screen printing machines are designed for high-volume production and efficiency. These machines automate the printing process, allowing for faster output and consistent quality across large batches. They are equipped with advanced features such as automatic screen registration and ink application, which significantly reduce the time and labor involved in printing. While the initial cost of automatic machines is higher, the long-term benefits in terms of productivity and reduced labor costs can make them a worthwhile investment for businesses looking to scale their operations.

Furthermore, there are hybrid screen printing machines that combine both manual and automatic features. These machines offer flexibility, allowing operators to switch between manual and automated modes depending on the job requirements. This versatility can be particularly advantageous for businesses that handle a diverse range of projects, from small custom orders to larger production runs. By investing in a hybrid machine, companies can adapt to varying demands without the need for multiple machines, thus optimizing their workspace and resources.

In addition to the type of machine, it is essential to consider the size and configuration of the screen printing setup. For instance, some machines are designed for flatbed printing, which is suitable for items like t-shirts and posters, while others may be configured for cylindrical printing, ideal for items such as bottles and cans. The choice of configuration will largely depend on the types of products a business intends to print. Moreover, the size of the machine should align with the available workspace and production capacity, ensuring that it fits seamlessly into the existing workflow.

Another critical factor to consider is the ease of use and maintenance of the machine. Some models come with user-friendly interfaces and require minimal training, which can be beneficial for businesses with limited experience in screen printing. Additionally, machines that are easy to clean and maintain can save time and reduce downtime, further enhancing productivity.

Ultimately, choosing the best professional screen printing machine involves a careful evaluation of the specific needs of the business, including production volume, product types, and budget constraints. By comparing the various types of machines available, one can make a well-informed decision that not only meets current demands but also supports future growth. In this way, investing in the right screen printing machine can significantly impact the overall success and efficiency of a printing operation.

Budgeting for Your Screen Printing Equipment Investment

When embarking on the journey of selecting the best professional screen printing machine, one of the most critical aspects to consider is budgeting for your equipment investment. This process requires a careful evaluation of your financial resources, as well as an understanding of the various costs associated with screen printing machinery. By approaching this task methodically, you can ensure that your investment aligns with your business goals and operational needs.

To begin with, it is essential to establish a clear budget that reflects both your current financial situation and your long-term business objectives. This involves not only determining how much you can afford to spend upfront but also considering the ongoing costs associated with running a screen printing operation. These costs may include maintenance, supplies, and potential upgrades, all of which can significantly impact your overall budget. Therefore, it is prudent to create a comprehensive financial plan that encompasses both initial and recurring expenses.

Once you have a budget in place, the next step is to research the various types of screen printing machines available on the market. The price range for these machines can vary widely, depending on factors such as brand reputation, machine capabilities, and production capacity. For instance, entry-level machines may be more affordable but could lack the features necessary for high-volume production. Conversely, high-end models may offer advanced technology and greater efficiency but come with a higher price tag. By understanding the different options available, you can make an informed decision that balances cost with functionality.

In addition to the machine’s purchase price, it is crucial to factor in the cost of consumables and accessories. Screen printing requires various supplies, including screens, inks, squeegees, and emulsion. These materials can add up quickly, so it is wise to estimate your ongoing supply costs based on your expected production volume. Furthermore, consider the potential need for additional equipment, such as exposure units or drying racks, which can enhance your printing capabilities but will also contribute to your overall investment.

Moreover, it is beneficial to explore financing options that may be available to you. Many suppliers offer payment plans or leasing options that can help alleviate the financial burden of purchasing a professional screen printing machine. By spreading the cost over time, you can maintain cash flow while still acquiring the necessary equipment to grow your business. Additionally, some manufacturers may provide financing through third-party lenders, which can further expand your options.

As you navigate the budgeting process, it is also important to consider the potential return on investment (ROI) associated with your equipment choice. A higher-quality machine may require a larger initial investment but could lead to increased efficiency, reduced waste, and ultimately higher profit margins. Therefore, it is essential to weigh the long-term benefits against the upfront costs to determine the best course of action for your business.

In conclusion, budgeting for your screen printing equipment investment is a multifaceted process that requires careful consideration of various factors. By establishing a clear budget, researching machine options, factoring in ongoing costs, exploring financing solutions, and evaluating potential ROI, you can make a well-informed decision that supports your business’s growth and success. Ultimately, a thoughtful approach to budgeting will enable you to select the best professional screen printing machine that meets your needs while ensuring a sustainable financial future.

Pre: Why the Riley Hopkins 4 Color Press is a Favorite Among Professionals

Next: How to Choose the Best Screen Printing Inks for Long-Lasting Prints

Tags: