How to Achieve Perfect Alignment on a 4 Color Screen Printing Press

Tips for Achieving Perfect Alignment on a 4 Color Screen Printing Press

Achieving perfect alignment on a 4 color screen printing press is essential for producing high-quality prints. Proper alignment ensures that each color is accurately registered on the substrate, resulting in crisp and vibrant designs. While achieving perfect alignment may seem daunting, with the right techniques and attention to detail, it can be achieved consistently.

One of the first steps in achieving perfect alignment on a 4 color screen printing press is to ensure that the press itself is properly set up. This includes making sure that the press is level and stable, as any movement or instability can lead to misalignment during the printing process. Additionally, checking that the screens are securely fastened to the press and that the registration marks are clearly visible is crucial for accurate alignment.

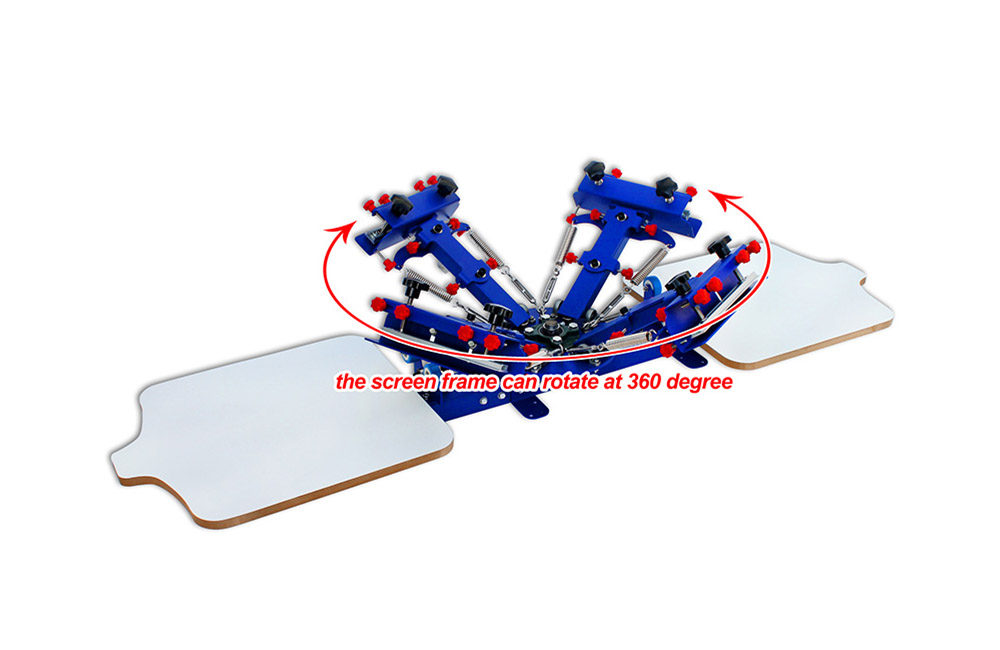

Once the press is set up correctly, the next step is to properly align the screens. This involves ensuring that each screen is positioned accurately on the press and that the registration marks on each screen are aligned with each other. One technique for achieving this is to use a registration jig, which can help to ensure that each screen is positioned consistently for each print run.

After the screens are aligned, the next step is to test print each color to check for alignment. This involves printing each color individually onto a test substrate and checking that the colors line up correctly. If any misalignment is detected, adjustments can be made to the screen position or the press settings to correct the issue.

One common technique for adjusting alignment is to use micro-registration knobs on the press. These knobs allow for precise adjustments to be made to the screen position, helping to fine-tune the alignment of each color. By making small adjustments and testing the alignment after each adjustment, perfect alignment can be achieved.

Another important factor in achieving perfect alignment on a 4 color screen printing press is to ensure that the screens are properly tensioned. Screens that are too loose or too tight can lead to misalignment during the printing process. By regularly checking and adjusting the tension of the screens, you can help to maintain consistent alignment throughout the print run.

In addition to proper press setup and screen alignment, it is also important to use high-quality inks and substrates for screen printing. Using inks that are specifically designed for screen printing and substrates that are compatible with the inks can help to ensure that the colors are vibrant and that the prints are durable.

Overall, achieving perfect alignment on a 4 color screen printing press requires attention to detail, patience, and practice. By following the proper techniques and regularly checking and adjusting alignment throughout the print run, you can consistently produce high-quality prints with crisp and vibrant colors. With dedication and a focus on precision, perfect alignment can be achieved on a 4 color screen printing press.

Pre: How to Print with Precision Using a Multi-Color Screen Printing Press

Next: Screen Printing vs. Heat Transfer: Which Is Best for Your Business?

Tags: