How a Rotary Screen Printing Press Can Improve Production Efficiency

Reduced Downtime with Rotary Screen Printing Press

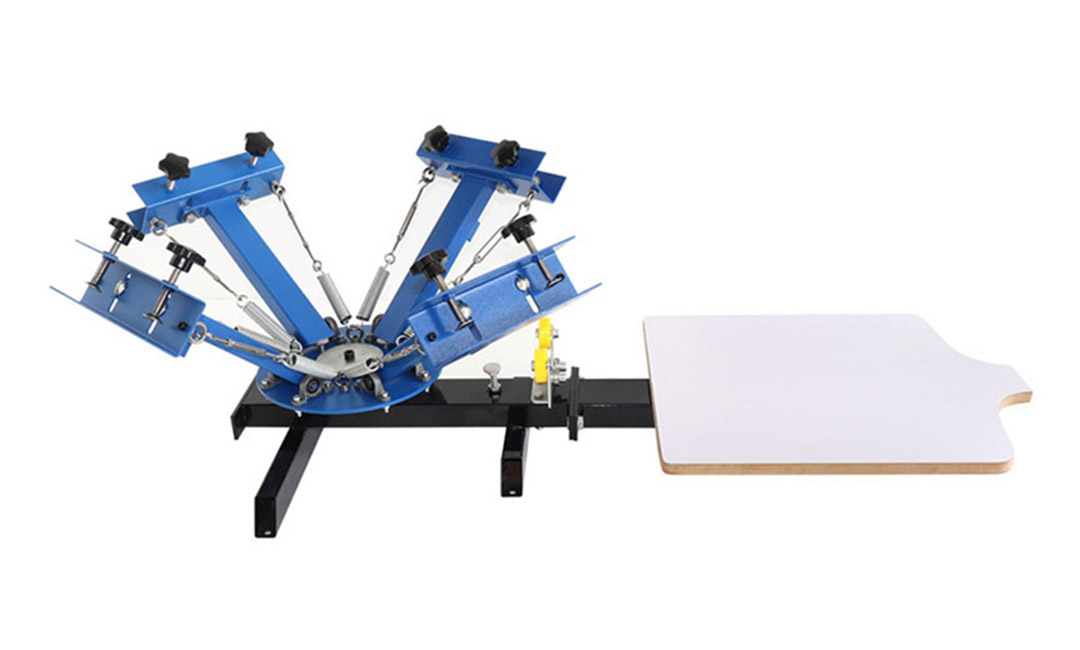

In the fast-paced world of printing, efficiency is key to staying competitive and meeting customer demands. One way to improve production efficiency in the printing industry is by utilizing a rotary screen printing press. This innovative technology offers a number of benefits that can help reduce downtime and increase productivity.

One of the main advantages of a rotary screen printing press is its ability to handle high-volume printing jobs with speed and precision. Unlike traditional flatbed printing presses, which require multiple passes to achieve the desired results, a rotary screen press can print multiple colors in a single pass. This not only saves time but also reduces the risk of errors and inconsistencies in the final product.

Another key benefit of a rotary screen printing press is its versatility. These machines are capable of printing on a wide range of substrates, including paper, cardboard, plastic, and fabric. This flexibility allows printers to take on a variety of projects without the need for multiple machines or setups, saving time and resources in the process.

In addition to its speed and versatility, a rotary screen printing press can also help reduce downtime in a number of ways. One common cause of downtime in the printing industry is the need to change out screens for different jobs. With a rotary screen press, screens can be easily swapped out in a matter of minutes, allowing printers to quickly transition between projects without missing a beat.

Furthermore, rotary screen presses are designed for easy maintenance and troubleshooting. Many models come equipped with advanced monitoring systems that can alert operators to potential issues before they cause a breakdown. This proactive approach to maintenance can help prevent costly downtime and keep production running smoothly.

Overall, the use of a rotary screen printing press can have a significant impact on production efficiency in the printing industry. By reducing downtime, increasing speed, and improving versatility, these machines offer a number of advantages that can help printers stay competitive in a fast-paced market.

In conclusion, the benefits of a rotary screen printing press are clear. By investing in this innovative technology, printers can improve production efficiency, reduce downtime, and increase overall productivity. With its speed, versatility, and ease of maintenance, a rotary screen press is a valuable tool for any printing operation looking to stay ahead of the competition.

Increased Speed and Throughput with Rotary Screen Printing Press

Rotary screen printing presses have become a popular choice for many industries looking to improve their production efficiency. These presses offer a number of advantages over traditional flatbed printing methods, including increased speed and throughput. By utilizing a rotary screen printing press, businesses can significantly reduce their production times and increase their overall output.

One of the key benefits of using a rotary screen printing press is the increased speed at which it can operate. Unlike flatbed printing presses, which require the printing surface to move back and forth under the screen, rotary presses use a rotating cylinder to apply the ink to the substrate. This allows for much faster printing speeds, as the substrate can move continuously through the press without the need for frequent stops and starts.

In addition to increased speed, rotary screen printing presses also offer higher throughput capabilities. Because the printing process is continuous, these presses can handle a larger volume of work in a shorter amount of time. This is especially beneficial for businesses with high production demands, as it allows them to meet deadlines more efficiently and take on larger orders without sacrificing quality.

Another advantage of using a rotary screen printing press is the ability to achieve more intricate and detailed designs. The rotary cylinder can be engraved with extremely fine patterns, allowing for precise and high-resolution printing. This makes rotary presses ideal for applications that require complex designs or fine details, such as textiles, packaging, and labels.

Furthermore, rotary screen printing presses are highly versatile and can be used on a wide range of substrates, including paper, cardboard, plastics, and textiles. This flexibility makes them a valuable tool for businesses in various industries, as they can easily adapt to different printing needs and requirements.

Overall, the use of a rotary screen printing press can greatly improve production efficiency for businesses of all sizes. By increasing printing speeds, throughput capabilities, and design precision, these presses offer a cost-effective solution for meeting high-volume printing demands. Additionally, their versatility and adaptability make them a valuable asset for businesses looking to expand their printing capabilities and take on new opportunities in the market.

In conclusion, the benefits of using a rotary screen printing press are clear. With increased speed, throughput, and design capabilities, these presses offer a competitive advantage for businesses looking to improve their production efficiency. By investing in a rotary screen printing press, businesses can streamline their printing processes, increase their output, and ultimately achieve greater success in the market.

Enhanced Print Quality and Consistency with Rotary Screen Printing Press

Rotary screen printing presses have long been a popular choice for textile manufacturers looking to improve their production efficiency. These machines offer a number of advantages over traditional flatbed printing presses, including enhanced print quality and consistency. By utilizing a rotary screen printing press, manufacturers can achieve higher levels of precision and detail in their prints, resulting in a more professional and polished final product.

One of the key benefits of using a rotary screen printing press is the ability to achieve greater print consistency. Unlike flatbed presses, which rely on manual placement of screens and squeegees, rotary presses use a continuous rotary motion to apply ink to the fabric. This results in a more uniform application of ink, leading to prints that are more consistent in color and coverage. This level of consistency is essential for maintaining a high standard of quality in the final product.

In addition to improved consistency, rotary screen printing presses also offer enhanced print quality. The rotary motion of the press allows for greater control over the printing process, resulting in prints that are sharper and more detailed. This level of precision is particularly important for intricate designs or patterns, where even the smallest imperfection can be noticeable. By using a rotary screen printing press, manufacturers can ensure that their prints are of the highest quality, meeting the expectations of their customers and setting themselves apart from the competition.

Another advantage of using a rotary screen printing press is the ability to achieve faster production speeds. The continuous rotary motion of the press allows for rapid printing of large quantities of fabric, making it ideal for high-volume production runs. This increased speed not only improves efficiency but also allows manufacturers to meet tight deadlines and respond quickly to changing market demands. By investing in a rotary screen printing press, manufacturers can streamline their production process and increase their output without sacrificing quality.

Furthermore, rotary screen printing presses are highly versatile and can be used to print on a wide range of fabrics, including cotton, polyester, and silk. This flexibility allows manufacturers to expand their product offerings and cater to a diverse range of customers. Whether printing on t-shirts, curtains, or upholstery fabric, a rotary screen printing press can deliver high-quality results across a variety of applications.

In conclusion, a rotary screen printing press is a valuable tool for textile manufacturers looking to improve their production efficiency. By offering enhanced print quality and consistency, faster production speeds, and versatility in printing on different fabrics, these machines can help manufacturers meet the demands of a competitive market. Investing in a rotary screen printing press can lead to increased productivity, higher quality prints, and ultimately, greater success for manufacturers in the textile industry.

Pre: How to Choose a Small Business Screen Printer That Fits Your Needs

Next: How to Maximize Efficiency with the Best Screen Printing Machines

Tags: