How a 2 Station Screen Printing Press Enhances Production Efficiency

Benefits of Using a 2 Station Screen Printing Press

Screen printing is a popular method of printing that involves transferring ink onto a substrate through a mesh screen. This process is commonly used for printing on various materials such as textiles, paper, and plastics. One of the key components in screen printing is the screen printing press, which is used to hold the screen in place and apply pressure to transfer the ink onto the substrate.

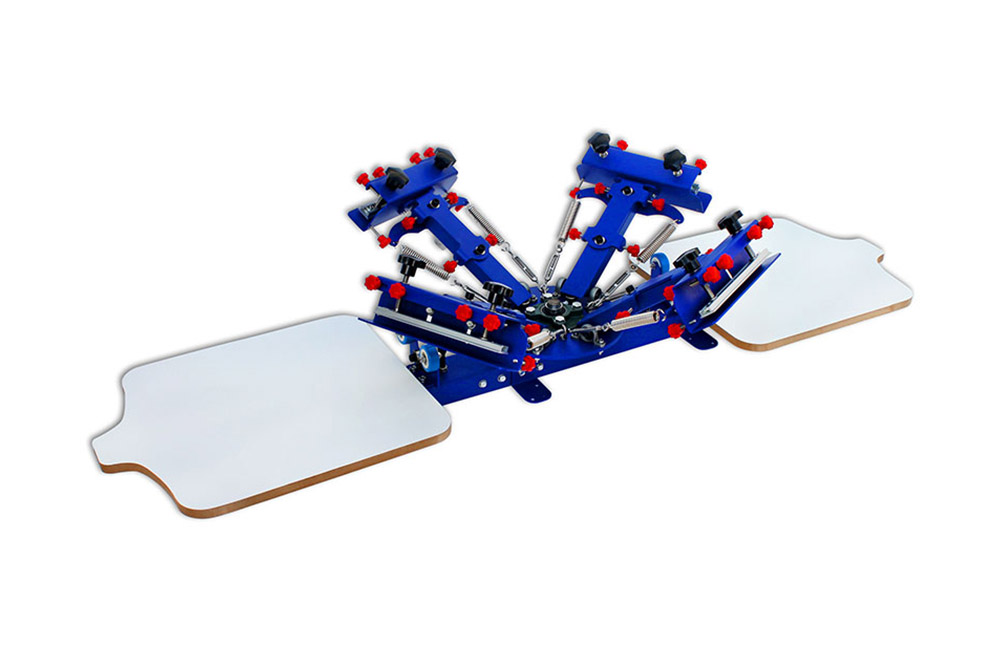

A 2 station screen printing press is a type of screen printing press that has two stations, allowing for two screens to be set up and printed simultaneously. This type of press offers several benefits that can enhance production efficiency for screen printing businesses.

One of the main advantages of using a 2 station screen printing press is the ability to increase production output. By having two stations, operators can set up two screens with different designs or colors and print them simultaneously. This can significantly reduce the time it takes to complete a print run, allowing for more orders to be processed in a shorter amount of time.

In addition to increasing production output, a 2 station screen printing press can also improve workflow efficiency. With two stations, operators can work on different tasks simultaneously, such as setting up screens, loading substrates, and printing. This can help streamline the printing process and reduce downtime between print runs.

Another benefit of using a 2 station screen printing press is the ability to easily switch between different designs or colors. With two stations, operators can quickly change out screens and ink colors without having to stop the press and reconfigure the setup. This can save valuable time and allow for more flexibility in fulfilling customer orders with different design requirements.

Furthermore, a 2 station screen printing press can help reduce labor costs by requiring fewer operators to run the press. With two stations, one operator can manage both stations, maximizing efficiency and reducing the need for additional labor. This can result in cost savings for screen printing businesses and improve overall profitability.

Overall, a 2 station screen printing press offers several benefits that can enhance production efficiency for screen printing businesses. From increasing production output and improving workflow efficiency to reducing labor costs and providing flexibility in design options, this type of press is a valuable tool for streamlining the screen printing process.

In conclusion, investing in a 2 station screen printing press can be a wise decision for screen printing businesses looking to improve their production efficiency. With the ability to increase output, streamline workflow, and reduce labor costs, this type of press can help businesses meet customer demands and achieve greater profitability. Consider incorporating a 2 station screen printing press into your operation to take advantage of these benefits and enhance your screen printing capabilities.

Pre: How to Maximize Efficiency with a 4 Color 2 Station Screen Printing Machine

Next: The Best 4 Color 2 Station Screen Printing Machines for Beginners and Experts

Tags: