Exploring the Features of 6 Color Screen Printing Presses

Advantages of 6 Color Screen Printing Presses

The advantages of 6 color screen printing presses are numerous and significant, making them a preferred choice for many businesses in the printing industry. One of the primary benefits of utilizing a 6 color screen printing press is the ability to produce vibrant and intricate designs. With six colors at their disposal, printers can achieve a broader spectrum of hues and shades, allowing for more detailed and visually appealing prints. This capability is particularly advantageous for businesses that require high-quality graphics, such as those in the fashion, promotional products, and custom merchandise sectors.

Moreover, the versatility of a 6 color screen printing press cannot be overstated. These machines can accommodate a wide range of substrates, including textiles, plastics, and paper, which makes them suitable for various applications. This adaptability enables businesses to diversify their product offerings, catering to different markets and customer preferences. As a result, companies can enhance their competitiveness and appeal to a broader audience, ultimately driving sales and growth.

In addition to versatility, the efficiency of 6 color screen printing presses is another compelling advantage. These presses are designed to streamline the printing process, allowing for faster production times without compromising quality. The ability to print multiple colors in a single pass reduces the need for multiple setups and adjustments, which can be time-consuming and labor-intensive. Consequently, businesses can increase their output and meet tight deadlines more effectively, thereby improving overall productivity.

Furthermore, the durability of prints produced by 6 color screen printing presses is noteworthy. The inks used in screen printing are typically more resilient than those used in other printing methods, such as digital printing. This durability ensures that the final products can withstand wear and tear, making them ideal for items that will be subjected to frequent use or exposure to the elements. As a result, customers are more likely to be satisfied with their purchases, leading to repeat business and positive word-of-mouth referrals.

Another significant advantage of 6 color screen printing presses is the cost-effectiveness they offer, particularly for large production runs. While the initial investment in a high-quality press may be substantial, the long-term savings can be considerable. The efficiency of these machines allows businesses to produce large quantities of prints at a lower cost per unit, which is especially beneficial for companies that require bulk orders. Additionally, the longevity of the prints reduces the need for frequent reprints, further contributing to cost savings over time.

Moreover, the creative possibilities afforded by a 6 color screen printing press are virtually limitless. Designers can experiment with various techniques, such as layering colors, creating gradients, and incorporating special effects like metallic or fluorescent inks. This creative freedom not only enhances the aesthetic appeal of the products but also allows businesses to differentiate themselves in a crowded marketplace. By offering unique and eye-catching designs, companies can establish a strong brand identity and attract a loyal customer base.

In conclusion, the advantages of 6 color screen printing presses are manifold, encompassing vibrant color reproduction, versatility, efficiency, durability, cost-effectiveness, and creative potential. These features make them an invaluable asset for businesses looking to enhance their printing capabilities and meet the diverse needs of their customers. As the printing industry continues to evolve, investing in advanced technology such as 6 color screen printing presses will undoubtedly position companies for success in an increasingly competitive landscape.

Key Features to Look for in 6 Color Screen Printing Equipment

When considering the acquisition of a six-color screen printing press, it is essential to understand the key features that can significantly impact the efficiency and quality of your printing operations. First and foremost, the construction and build quality of the press should be evaluated. A robust frame made from high-quality materials, such as steel or aluminum, ensures durability and stability during the printing process. This stability is crucial, as it minimizes vibrations that can lead to misalignment and inconsistencies in print quality.

In addition to the frame, the design of the press plays a vital role in its functionality. A well-designed six-color screen printing press should offer a user-friendly interface that allows for easy adjustments and setup. Features such as micro-registration systems are particularly important, as they enable precise alignment of colors, which is essential for achieving high-quality prints. The ability to make fine adjustments quickly can save time and reduce material waste, making the printing process more efficient.

Moreover, the type of printing method employed by the press is another critical aspect to consider. Automatic presses, for instance, can significantly increase production speed compared to manual presses. They often come equipped with advanced features such as automatic squeegee and flood bar controls, which enhance consistency and reduce the physical strain on operators. Conversely, manual presses may offer greater flexibility for small runs or custom jobs, allowing for more hands-on control over the printing process. Therefore, understanding the specific needs of your business will help determine which type of press is most suitable.

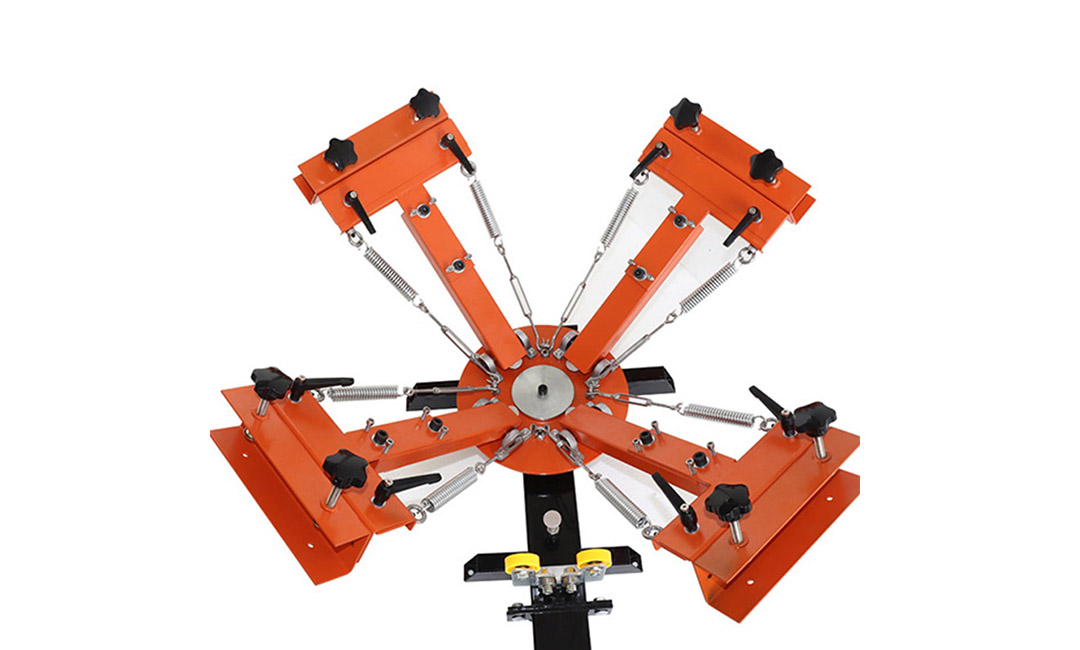

Another important feature to look for is the number of print heads and their configuration. A six-color press typically allows for a variety of color combinations and layering techniques, which can enhance the creative possibilities for designs. However, the arrangement of the print heads can also affect the ease of use and maintenance. For instance, presses with a rotary or carousel design often facilitate smoother operation and quicker color changes, which can be advantageous in a busy production environment.

Furthermore, the ability to accommodate different screen sizes and types is essential for versatility. A good six-color screen printing press should be compatible with various mesh counts and screen sizes, allowing printers to experiment with different inks and techniques. This adaptability can be particularly beneficial for businesses that cater to a diverse clientele with varying printing needs.

In addition to these technical features, it is also important to consider the support and resources provided by the manufacturer. A reputable company will offer comprehensive training, customer support, and access to replacement parts, which can be invaluable in maintaining the longevity and performance of the equipment. Investing in a press from a manufacturer known for its reliability and customer service can provide peace of mind and ensure that your operations run smoothly.

Ultimately, selecting the right six-color screen printing press involves a careful assessment of these key features. By prioritizing build quality, design, printing method, print head configuration, compatibility with various screens, and manufacturer support, businesses can make informed decisions that enhance their printing capabilities. This thoughtful approach not only improves production efficiency but also elevates the quality of the final printed products, thereby contributing to overall customer satisfaction and business success.

Tips for Maximizing Efficiency with 6 Color Screen Printing Presses

Maximizing efficiency with 6 color screen printing presses requires a combination of strategic planning, proper maintenance, and an understanding of the equipment’s capabilities. To begin with, it is essential to familiarize oneself with the specific features of the press being used. Each model may have unique attributes that can enhance productivity, such as adjustable squeegee pressure, quick-release clamps, or automatic registration systems. By taking the time to understand these features, operators can leverage them to streamline their workflow.

In addition to understanding the equipment, preparation plays a crucial role in maximizing efficiency. Before starting a print run, it is advisable to gather all necessary materials, including screens, inks, and substrates. Organizing these items in a designated workspace can significantly reduce downtime. Furthermore, pre-mixing inks to the desired colors can save valuable time during the printing process. This proactive approach not only minimizes interruptions but also ensures that the printing process flows smoothly from one color to the next.

Another important aspect of efficiency is the setup process. When working with a 6 color screen printing press, it is vital to ensure that screens are properly aligned and registered. Utilizing registration marks can aid in achieving precise alignment, which is particularly important when printing multi-color designs. Additionally, employing a consistent setup routine can help operators become more proficient over time, reducing the likelihood of errors and the need for adjustments during production.

Moreover, maintaining the equipment is essential for optimal performance. Regular cleaning and maintenance of screens, squeegees, and the press itself can prevent issues that may lead to delays. For instance, ink buildup on screens can cause misprints or color contamination, which can be time-consuming to rectify. Establishing a routine maintenance schedule not only prolongs the life of the equipment but also ensures that it operates at peak efficiency.

In conjunction with maintenance, training staff on best practices can significantly enhance productivity. Ensuring that all operators are well-versed in the operation of the press and the intricacies of screen printing can lead to a more cohesive workflow. Regular training sessions can also introduce new techniques or updates on equipment features, fostering an environment of continuous improvement. This investment in human resources can yield substantial returns in terms of efficiency and output quality.

Furthermore, embracing technology can also contribute to maximizing efficiency. Many modern 6 color screen printing presses come equipped with advanced features such as digital controls and automated functions. Utilizing these technologies can reduce manual labor and minimize human error, allowing for faster production times. Additionally, software solutions for design and color management can streamline the pre-press process, ensuring that designs are print-ready before they reach the press.

Lastly, it is important to monitor production metrics to identify areas for improvement. Keeping track of print runs, setup times, and any issues that arise can provide valuable insights into the efficiency of the operation. By analyzing this data, operators can pinpoint bottlenecks and implement changes to enhance overall productivity. In conclusion, maximizing efficiency with 6 color screen printing presses involves a multifaceted approach that includes understanding the equipment, thorough preparation, diligent maintenance, effective training, and the integration of technology. By focusing on these areas, operators can significantly improve their workflow and achieve higher levels of productivity in their screen printing endeavors.

Pre: How Compact Screen Printing Equipment Can Improve Your Workflow

Next: Where to Take Screen Printing Classes and Learn the Craft

Tags: