Expert Tips on Enhancing Output with a 2 Station Screen Printing Press

Benefits of Using a 2 Station Screen Printing Press

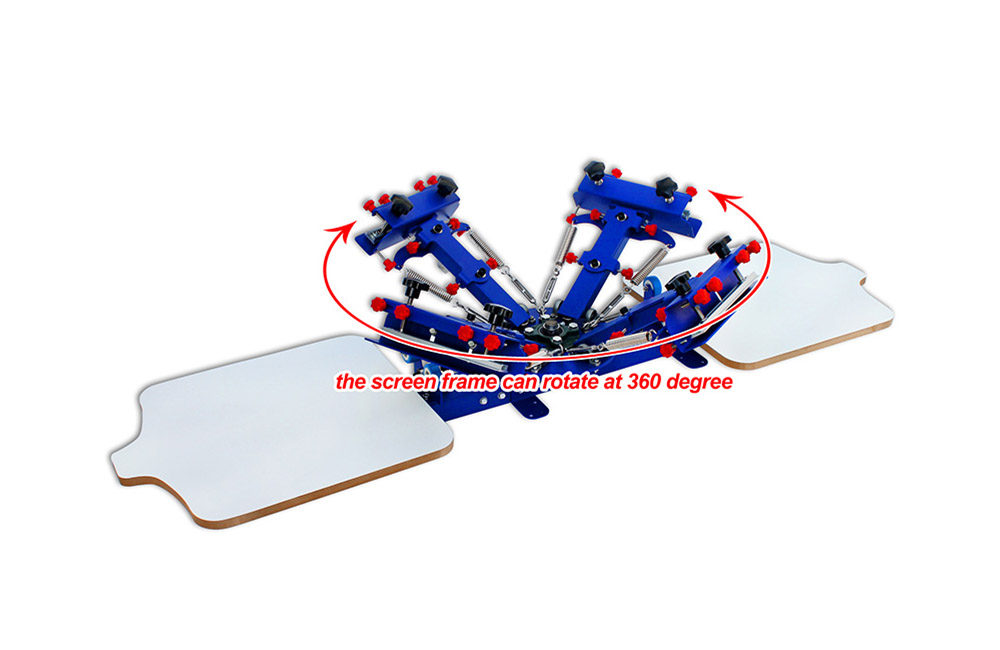

Screen printing is a popular method of printing that involves transferring ink onto a substrate through a mesh screen. This process is commonly used for printing on textiles, such as t-shirts, hoodies, and tote bags. One of the key components of a successful screen printing operation is the screen printing press. A 2 station screen printing press is a versatile and efficient tool that can help enhance output and streamline the printing process.

One of the main benefits of using a 2 station screen printing press is its ability to increase productivity. With two stations, operators can load and unload garments on one station while printing on the other. This allows for a continuous workflow, reducing downtime and increasing the number of items that can be printed in a given time frame. By maximizing efficiency, a 2 station screen printing press can help businesses meet tight deadlines and fulfill large orders with ease.

In addition to boosting productivity, a 2 station screen printing press can also improve print quality. The dual station design ensures that each garment is properly aligned and secured during the printing process, resulting in crisp and consistent prints. This is especially important when printing multi-color designs or intricate patterns, as any misalignment can lead to smudged or distorted prints. With a 2 station screen printing press, operators can achieve precise registration and produce high-quality prints that meet customer expectations.

Another advantage of using a 2 station screen printing press is its versatility. These presses are compatible with a wide range of substrates, including cotton, polyester, and blends. They can also accommodate various sizes of garments, from small children’s t-shirts to oversized adult hoodies. This flexibility allows businesses to offer a diverse range of products and cater to different customer preferences. Whether printing for a small boutique or a large-scale event, a 2 station screen printing press can handle a variety of printing jobs with ease.

To maximize the benefits of a 2 station screen printing press, it is important to follow some expert tips. First and foremost, proper maintenance is key to ensuring the longevity and performance of the press. Regularly clean the screens, squeegees, and platens to prevent ink buildup and maintain optimal print quality. Additionally, check for any loose bolts or worn parts that may need to be replaced to avoid downtime during production.

Another tip for enhancing output with a 2 station screen printing press is to experiment with different printing techniques and inks. Try using specialty inks, such as metallic or glow-in-the-dark, to create unique and eye-catching designs. Consider incorporating techniques like halftones or gradients to add depth and dimension to your prints. By exploring new possibilities, you can expand your product offerings and attract a wider range of customers.

In conclusion, a 2 station screen printing press is a valuable tool for enhancing output and improving efficiency in a screen printing operation. By increasing productivity, improving print quality, and offering versatility, these presses can help businesses meet the demands of a competitive market. By following expert tips on maintenance and experimentation, operators can maximize the benefits of a 2 station screen printing press and take their printing business to the next level.

Pre: Beginner’s Guide to Setting Up a Tabletop Screen Printing Press

Next: Portable Screen Printing Machines: Perfect for On-the-Go Creatives

Tags: