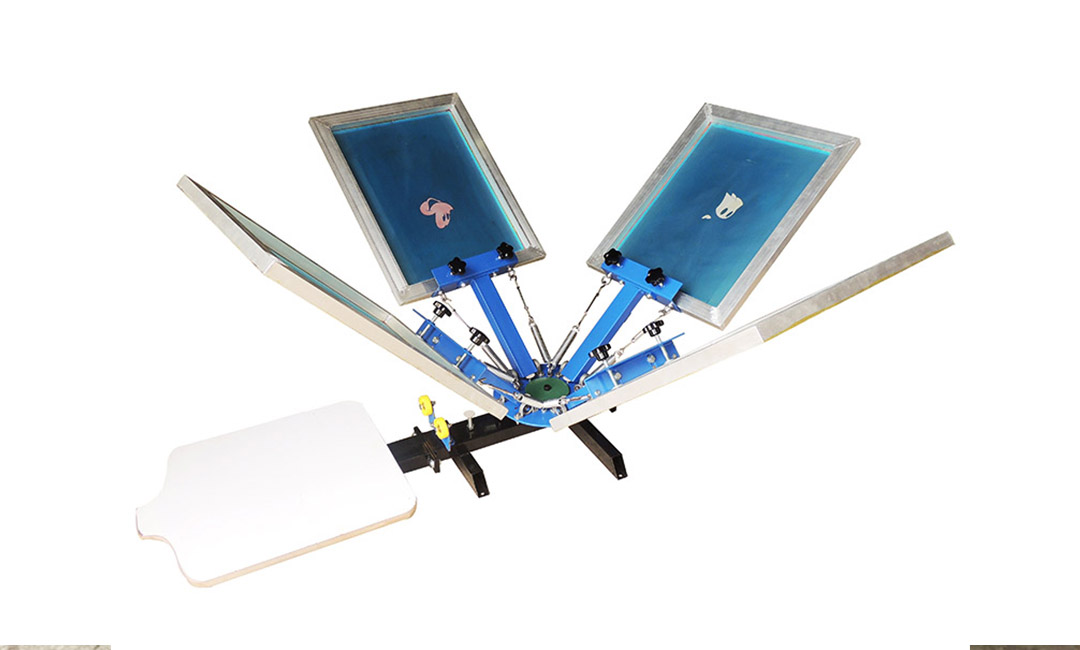

Expert Tips for Mastering a 4 Color One Station Screen Printing Press

Proper Screen Preparation Techniques

Screen printing is a popular method of printing designs onto various surfaces, such as t-shirts, posters, and more. One of the key components of successful screen printing is proper screen preparation. In this article, we will discuss expert tips for mastering a 4 color one station screen printing press.

The first step in preparing your screen for printing is to ensure that it is clean and free of any debris. This can be achieved by using a screen degreaser to remove any oils or dirt that may be present on the screen. Once the screen is clean, it is important to ensure that it is completely dry before moving on to the next step.

After the screen is clean and dry, the next step is to apply emulsion to the screen. Emulsion is a light-sensitive material that is used to create the stencil for your design. To apply the emulsion, use a scoop coater to evenly coat both sides of the screen with a thin layer of emulsion. Be sure to apply the emulsion in a dark room or under a yellow light, as exposure to regular light can cause the emulsion to harden prematurely.

Once the emulsion has been applied, the next step is to expose the screen to light. This is where the design for your print will be transferred onto the screen. To do this, place your design on a transparency film and lay it on top of the screen. Use a light table or exposure unit to expose the screen to UV light for the appropriate amount of time. The emulsion will harden where the light hits it, creating a stencil of your design on the screen.

After the screen has been exposed, it is important to wash out the unexposed emulsion. This can be done using a pressure washer or a garden hose with a spray nozzle attachment. Be sure to wash both sides of the screen thoroughly to remove any unexposed emulsion. Once the screen is clean, allow it to dry completely before moving on to the next step.

The final step in preparing your screen for printing is to tape off any areas that you do not want ink to pass through. This can be done using masking tape or screen blockout. Be sure to tape off any areas that are not part of your design to ensure clean and crisp prints.

In conclusion, proper screen preparation is essential for successful screen printing. By following these expert tips, you can master a 4 color one station screen printing press and create high-quality prints with ease. Remember to keep your screen clean, apply emulsion evenly, expose the screen properly, wash out the unexposed emulsion, and tape off any unwanted areas. With practice and attention to detail, you can achieve professional results with your screen printing projects.

Ink Mixing and Color Matching Tips

Screen printing is a popular method of printing that involves transferring ink onto a substrate through a mesh screen. One of the most common types of screen printing presses is the 4 color one station press, which allows for printing with up to four different colors in one pass. Mastering this type of press requires attention to detail and precision, especially when it comes to ink mixing and color matching.

When working with a 4 color one station screen printing press, it is essential to have a good understanding of ink mixing and color matching. This will ensure that your prints come out looking crisp and vibrant, with colors that are true to the original design. Here are some expert tips to help you master ink mixing and color matching on a 4 color one station press.

First and foremost, it is crucial to use high-quality inks that are specifically designed for screen printing. These inks are formulated to provide excellent color saturation and durability, ensuring that your prints will look great and last a long time. It is also important to use the right type of ink for the substrate you are printing on, whether it be fabric, paper, or another material.

When mixing inks for screen printing, it is important to be precise and consistent. Start by measuring out the exact amounts of each color you will need for your print job. Use a scale to ensure accuracy, as even small variations in ink ratios can result in noticeable differences in color. Mix the inks thoroughly to ensure that the colors are evenly distributed and there are no streaks or clumps.

Color matching is another crucial aspect of screen printing, especially when working with multiple colors. To ensure that your colors are consistent across all prints, it is important to create a color reference guide. This guide should include swatches of each color you will be using, along with the exact ink ratios and mixing instructions for each color. Refer to this guide each time you mix ink to ensure that your colors are consistent and accurate.

When printing with a 4 color one station press, it is important to pay attention to registration. Registration refers to the alignment of each color layer on the substrate, and it is crucial for creating crisp, clean prints. Use registration marks on your screens and substrate to ensure that each color layer lines up perfectly. Make adjustments as needed to ensure that all colors are aligned correctly.

Ink curing is another important step in the screen printing process. After printing, the ink must be cured to ensure that it adheres properly to the substrate and will not wash or fade over time. Follow the manufacturer’s instructions for curing the ink, whether it be through heat curing, air drying, or another method. Proper curing will ensure that your prints are durable and long-lasting.

In conclusion, mastering a 4 color one station screen printing press requires attention to detail and precision, especially when it comes to ink mixing and color matching. By using high-quality inks, being precise in your mixing, creating a color reference guide, paying attention to registration, and properly curing your prints, you can create professional-quality prints that are vibrant and long-lasting. With practice and attention to detail, you can become an expert at using a 4 color one station press for all your screen printing needs.

Troubleshooting Common Printing Issues

Screen printing is a popular method of printing that involves transferring ink onto a substrate through a mesh screen. One of the most common types of screen printing presses is the 4 color one station press, which allows for printing with up to four different colors in one pass. While this type of press can produce high-quality prints, there are some common issues that can arise during the printing process. In this article, we will discuss some expert tips for mastering a 4 color one station screen printing press and troubleshooting common printing issues.

One of the most important aspects of successful screen printing is proper setup and registration. Registration refers to the alignment of the different colors on the print, and it is crucial for achieving crisp and clean prints. To ensure proper registration, it is important to carefully set up the press and make sure that all screens are aligned correctly. This can be done by using registration marks on the screens and substrate, as well as adjusting the micro-registration knobs on the press.

Another common issue that can arise during screen printing is ink bleeding or smudging. This can occur when too much ink is applied to the screen or when the squeegee is pressed too hard against the substrate. To prevent ink bleeding, it is important to use the right amount of ink and apply it evenly to the screen. Additionally, using the correct squeegee pressure and angle can help prevent smudging and ensure clean prints.

In some cases, prints may come out blurry or distorted, which can be caused by improper screen tension. Screen tension refers to the tightness of the mesh screen, and it is important for achieving sharp and clear prints. To ensure proper screen tension, it is important to regularly check and adjust the tension of the screens using a tension meter. Additionally, using high-quality screens and mesh can help prevent issues with screen tension and improve print quality.

Another common issue that can occur during screen printing is ghosting, which refers to faint or shadow images that appear on the print. Ghosting can be caused by a variety of factors, including improper screen exposure, dirty screens, or inadequate drying time. To prevent ghosting, it is important to properly expose the screens, clean them regularly, and allow enough time for the prints to dry before handling them.

Finally, one of the most important tips for mastering a 4 color one station screen printing press is practice and patience. Screen printing is a skill that takes time to master, and it is important to experiment with different techniques and materials to find what works best for you. By practicing regularly and learning from your mistakes, you can improve your screen printing skills and produce high-quality prints with your press.

In conclusion, mastering a 4 color one station screen printing press requires attention to detail, proper setup, and troubleshooting common printing issues. By following the expert tips outlined in this article, you can improve your screen printing skills and achieve professional results with your press. Remember to practice regularly, be patient, and don’t be afraid to experiment with different techniques to find what works best for you. With dedication and perseverance, you can become a master of screen printing with your 4 color one station press.

Pre: How a 4 in 1 Screen Printing Machine Can Streamline Your Printing Business

Next: Exploring the Capabilities of a 4 Color 1 Station Screen Printing Machine

Tags: