Everything You Need to Know About Operating a Riley Hopkins 4 Color Press

Proper Maintenance Techniques for Your Riley Hopkins 4 Color Press

Operating a Riley Hopkins 4 Color Press can be a rewarding experience for any screen printer. However, in order to ensure that your press continues to run smoothly and produce high-quality prints, it is important to properly maintain it. Proper maintenance techniques are essential for keeping your press in top condition and preventing costly repairs down the line.

One of the most important aspects of maintaining your Riley Hopkins 4 Color Press is keeping it clean. Regularly cleaning your press will help prevent ink buildup and ensure that all components are functioning properly. To clean your press, start by wiping down the exterior with a damp cloth to remove any dust or debris. Next, use a cleaning solution specifically designed for screen printing equipment to clean the platens, pallets, and other components of the press. Be sure to follow the manufacturer’s instructions when using any cleaning products to avoid damaging your press.

In addition to regular cleaning, it is important to lubricate the moving parts of your press to prevent wear and tear. Lubricating the press will help reduce friction and ensure that all components are moving smoothly. Be sure to use a lubricant that is compatible with your press and follow the manufacturer’s recommendations for how often to lubricate the various parts of the press.

Another important aspect of maintaining your Riley Hopkins 4 Color Press is checking for any loose or damaged parts. Regularly inspecting your press for loose bolts, screws, or other components will help prevent any issues that could affect the quality of your prints. If you notice any loose or damaged parts, be sure to tighten or replace them as soon as possible to prevent further damage to your press.

In addition to cleaning, lubricating, and inspecting your press, it is also important to calibrate your press regularly. Calibrating your press will ensure that all colors are aligned properly and that your prints are coming out as intended. To calibrate your press, follow the manufacturer’s instructions for adjusting the off-contact, angle, and pressure settings. Regularly calibrating your press will help ensure that you are producing high-quality prints consistently.

Proper maintenance of your Riley Hopkins 4 Color Press is essential for keeping it running smoothly and producing high-quality prints. By regularly cleaning, lubricating, inspecting, and calibrating your press, you can prevent costly repairs and ensure that your press continues to perform at its best. Taking the time to properly maintain your press will not only extend its lifespan but also improve the quality of your prints. So, be sure to follow these maintenance techniques to keep your Riley Hopkins 4 Color Press in top condition.

Troubleshooting Common Issues with Your Riley Hopkins 4 Color Press

Operating a Riley Hopkins 4 Color Press can be a rewarding experience for screen printers looking to produce high-quality prints efficiently. However, like any piece of equipment, there may be times when you encounter issues that can disrupt your workflow. In this article, we will discuss some common problems that may arise when operating a Riley Hopkins 4 Color Press and provide troubleshooting tips to help you resolve them quickly and effectively.

One of the most common issues that screen printers may encounter when using a Riley Hopkins 4 Color Press is registration problems. Registration refers to the alignment of the different colors in a design, and if not properly aligned, it can result in misprints and wasted materials. To troubleshoot registration issues, start by checking the tightness of the registration knobs on the press. Make sure that they are securely tightened to ensure that the screens are properly aligned. Additionally, check the off-contact settings to ensure that the screens are at the correct height relative to the printing surface.

Another common issue that screen printers may face is ink smudging or bleeding. This can occur when the ink is not properly cured or when too much ink is applied to the screen. To troubleshoot ink smudging or bleeding, start by adjusting the off-contact settings to ensure that the screens are not pressing too firmly against the printing surface. Additionally, check the curing temperature and time to ensure that the ink is properly cured before moving on to the next color.

In some cases, screen printers may encounter issues with uneven ink coverage on the print. This can be caused by a variety of factors, including uneven pressure on the squeegee or improper screen tension. To troubleshoot uneven ink coverage, start by checking the tension of the screens to ensure that they are evenly tensioned. Additionally, adjust the pressure on the squeegee to ensure that it is applying consistent pressure across the entire print area.

Another common issue that screen printers may face is ghosting, which refers to the faint outlines of previous prints that appear on subsequent prints. Ghosting can be caused by a variety of factors, including improper screen cleaning or insufficient drying time between prints. To troubleshoot ghosting, start by thoroughly cleaning the screens between prints to remove any residual ink. Additionally, allow sufficient drying time between prints to ensure that the ink is fully cured before moving on to the next print.

In conclusion, operating a Riley Hopkins 4 Color Press can be a rewarding experience for screen printers looking to produce high-quality prints efficiently. However, like any piece of equipment, there may be times when you encounter issues that can disrupt your workflow. By following the troubleshooting tips outlined in this article, you can quickly and effectively resolve common problems that may arise when operating a Riley Hopkins 4 Color Press. Remember to regularly maintain and calibrate your press to ensure optimal performance and quality prints.

Tips for Maximizing Efficiency and Productivity with Your Riley Hopkins 4 Color Press

Operating a Riley Hopkins 4 Color Press can be a rewarding experience for any screen printing business. This versatile machine allows for high-quality prints with vibrant colors, making it a popular choice among printers. However, to maximize efficiency and productivity with your Riley Hopkins 4 Color Press, there are a few key tips to keep in mind.

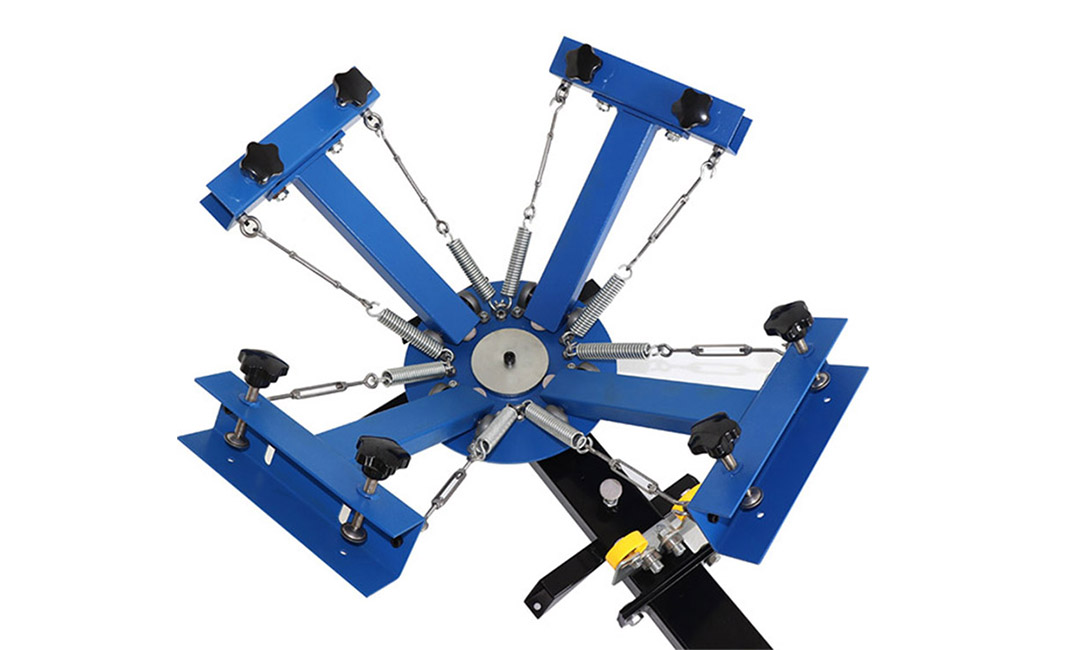

First and foremost, it is essential to familiarize yourself with the machine’s components and how they work together. The Riley Hopkins 4 Color Press consists of four print heads, each with its own set of screens and squeegees. Understanding how these components interact is crucial for achieving consistent and accurate prints.

When setting up your Riley Hopkins 4 Color Press, make sure to properly align the screens and squeegees to ensure that each color is printed in the correct location. This will help prevent misprints and wasted materials, saving you time and money in the long run.

In addition to proper alignment, it is important to maintain a clean work environment when operating your Riley Hopkins 4 Color Press. Dust and debris can easily accumulate on the screens and squeegees, leading to poor print quality. Regularly cleaning and inspecting these components will help ensure that your prints are crisp and clear.

Another tip for maximizing efficiency with your Riley Hopkins 4 Color Press is to use high-quality inks and emulsions. Investing in premium materials will not only improve the overall quality of your prints but also reduce the likelihood of equipment malfunctions and downtime.

When it comes to printing with multiple colors, it is crucial to have a well-thought-out plan in place. Consider the order in which you will print each color and how they will overlap to create the final design. This will help streamline the printing process and minimize the risk of errors.

Furthermore, experimenting with different printing techniques and settings can help you discover new ways to improve efficiency and productivity with your Riley Hopkins 4 Color Press. Don’t be afraid to try out different squeegee angles, print speeds, and pressure settings to see what works best for your specific needs.

Lastly, regular maintenance and upkeep of your Riley Hopkins 4 Color Press are essential for ensuring its longevity and performance. Be sure to lubricate moving parts, tighten loose screws, and replace worn-out components as needed. By taking care of your machine, you can avoid costly repairs and downtime in the future.

In conclusion, operating a Riley Hopkins 4 Color Press can be a rewarding experience when done correctly. By following these tips for maximizing efficiency and productivity, you can achieve high-quality prints with ease. Familiarize yourself with the machine’s components, maintain a clean work environment, use high-quality materials, plan your prints carefully, experiment with different techniques, and prioritize regular maintenance. With these strategies in place, you can make the most of your Riley Hopkins 4 Color Press and take your screen printing business to the next level.

Pre: Choosing the Best Table Mount Screen Printer for Your Home Studio

Next: Choosing the Right Exposure Unit for Perfect Screen Prints

Tags: