Enhancing Precision with 4 Color 1 Station Screen Printing Press with Micro Registration

Benefits of Using Micro Registration in Screen Printing

Screen printing has long been a popular method for creating high-quality prints on various surfaces, from t-shirts to posters to signage. One of the key factors that determine the quality of a screen print is the precision with which the design is aligned on the substrate. This is where micro registration comes into play, offering a level of accuracy that can elevate the final product to a whole new level.

Micro registration refers to the ability to make minute adjustments to the position of the screen on the printing press. This allows for precise alignment of multiple colors in a design, ensuring that each color is perfectly placed on the substrate. The result is a crisp, clean print that accurately reflects the original design.

One of the key benefits of using micro registration in screen printing is the ability to achieve complex and detailed designs with multiple colors. With traditional screen printing presses, aligning multiple colors can be a challenging and time-consuming process. However, with a 4 color 1 station screen printing press with micro registration, the process becomes much more streamlined and efficient.

The precision offered by micro registration also allows for greater consistency in the final product. Each print will be virtually identical, with no variation in color alignment or registration. This is particularly important for commercial screen printers who need to produce large quantities of prints that all look the same.

Another benefit of using micro registration in screen printing is the ability to achieve tighter registration tolerances. This means that the colors in a design can be aligned with even greater accuracy, resulting in prints that are truly flawless. This level of precision is especially important for intricate designs or designs that require a high level of detail.

In addition to improving the quality of the final product, micro registration can also help to reduce waste and increase efficiency in the screen printing process. By ensuring that each color is aligned correctly from the start, there is less chance of misprints or errors that result in wasted materials. This can ultimately save time and money for screen printers, making their operations more cost-effective.

Overall, the benefits of using a 4 color 1 station screen printing press with micro registration are clear. From achieving complex and detailed designs with multiple colors to improving consistency and efficiency in the printing process, micro registration offers a range of advantages for screen printers. By investing in a screen printing press with micro registration capabilities, printers can take their work to the next level and produce prints that are truly exceptional.

Tips for Achieving Precise Registration with a 4 Color 1 Station Press

Screen printing is a popular method of printing designs onto various surfaces, such as t-shirts, posters, and other promotional items. One of the key factors in achieving high-quality prints is precise registration, which refers to the alignment of different colors in a design. To achieve precise registration, many screen printers use a 4 color 1 station screen printing press with micro registration.

A 4 color 1 station screen printing press allows printers to print designs with up to four different colors in one pass. This can significantly speed up the printing process and reduce the chances of misalignment between colors. However, achieving precise registration with a 4 color 1 station press can be challenging, especially when working with intricate designs or small details.

One of the key features of a 4 color 1 station screen printing press that can help improve registration accuracy is micro registration. Micro registration allows printers to make small adjustments to the position of each color screen, ensuring that they are perfectly aligned with each other. This can be particularly useful when working with designs that require precise color placement or when printing on dark or colored garments where misalignment is more noticeable.

To achieve precise registration with a 4 color 1 station press with micro registration, there are several tips that printers can follow. First and foremost, it is essential to properly set up the press before starting the printing process. This includes ensuring that the screens are securely attached to the press and that the registration knobs are properly adjusted.

When setting up the press, it is important to take your time and make small adjustments to ensure that each color screen is aligned correctly. This may involve using a registration jig or other alignment tools to help guide the placement of each screen. Additionally, it is important to check the alignment of each color screen before starting the printing process to avoid any misalignment issues later on.

During the printing process, it is important to pay close attention to the registration of each color. This may involve making small adjustments to the micro registration knobs as needed to ensure that the colors are aligned correctly. It is also important to check the registration of each color after each print run to ensure that any adjustments are made promptly.

Another tip for achieving precise registration with a 4 color 1 station press is to use high-quality screens and inks. Low-quality screens or inks can lead to poor registration and lower print quality. By investing in high-quality materials, printers can ensure that their prints are crisp and accurate.

In conclusion, achieving precise registration with a 4 color 1 station screen printing press with micro registration is essential for producing high-quality prints. By following these tips and taking the time to properly set up and adjust the press, printers can ensure that their designs are perfectly aligned and look professional. With practice and attention to detail, printers can master the art of precise registration and create stunning prints that stand out from the rest.

How to Enhance Print Quality and Consistency with Micro Registration Technology

Screen printing has long been a popular method for creating high-quality prints on various surfaces, from t-shirts to posters to signage. One of the key factors in achieving precise and consistent prints is the registration of the screens. Registration refers to the alignment of the different colors in a design so that they line up perfectly on the final print. Traditionally, achieving precise registration required a skilled printer and a lot of trial and error. However, with advancements in technology, screen printing presses with micro registration capabilities have made the process much easier and more accurate.

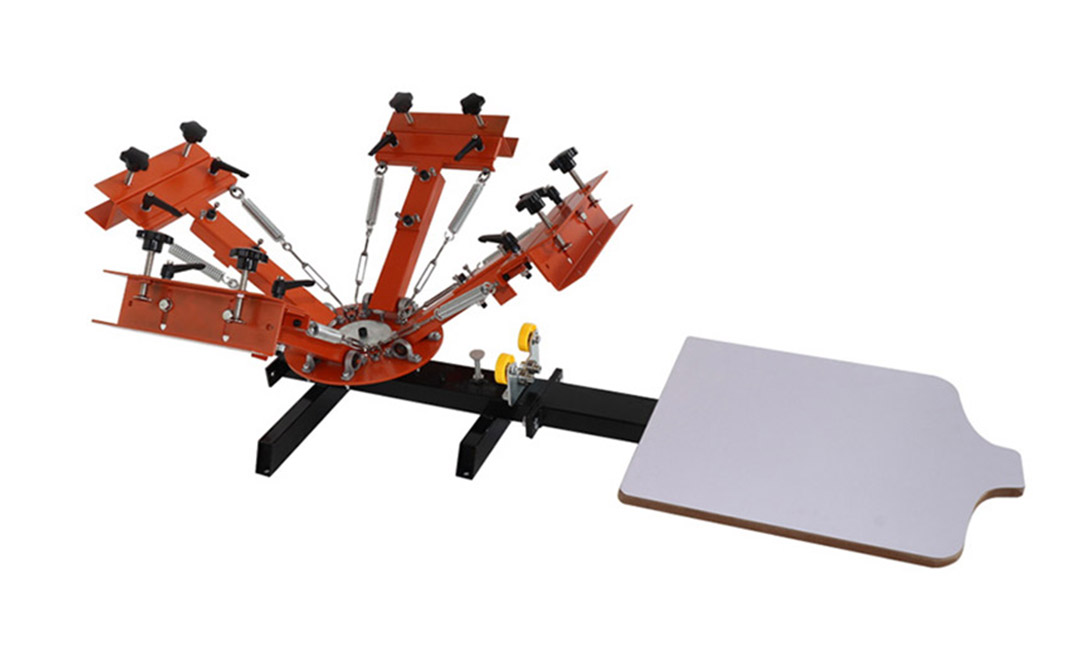

One such press that has gained popularity among screen printers is the 4 Color 1 Station Screen Printing Press with Micro Registration. This press allows for precise adjustments to be made to the position of each screen, ensuring that the colors align perfectly every time. The micro registration feature on this press allows for adjustments to be made in very small increments, giving the printer ultimate control over the registration process.

One of the key benefits of using a screen printing press with micro registration is the ability to achieve consistent print quality. With traditional screen printing presses, even the most skilled printer may struggle to achieve perfect registration on every print. However, with the precision offered by micro registration technology, prints can be produced with a level of consistency that was previously unattainable. This is especially important for commercial printers who need to produce large quantities of prints with the same design.

Another advantage of using a screen printing press with micro registration is the ability to achieve more complex and detailed designs. With traditional presses, intricate designs with multiple colors could be challenging to print accurately. However, with the precise adjustments that can be made with micro registration, even the most detailed designs can be printed with ease. This opens up a world of possibilities for screen printers, allowing them to take on more challenging projects and expand their capabilities.

In addition to improving print quality and consistency, using a screen printing press with micro registration can also save time and reduce waste. With traditional presses, a significant amount of time may be spent adjusting and readjusting the screens to achieve perfect registration. This can lead to wasted materials and increased production time. However, with the precise adjustments that can be made with micro registration, the registration process is streamlined, saving time and reducing waste.

Overall, the 4 Color 1 Station Screen Printing Press with Micro Registration is a valuable tool for screen printers looking to enhance their print quality and consistency. By utilizing the precision offered by micro registration technology, printers can achieve perfect registration on every print, produce more complex designs, and save time and reduce waste in the process. Whether you are a hobbyist looking to improve your prints or a commercial printer looking to expand your capabilities, a screen printing press with micro registration is a worthwhile investment.

Pre: Benefits of Using a 4 Color 1 Station Screen Printing Machine for Small Businesses

Next: Best Practices for Screen Printing with a 4 Color 1 Station System

Tags: