Efficient Workflow with a 2 Station Silk Screen Printing Press

Maximizing Productivity with a 2 Station Silk Screen Printing Press

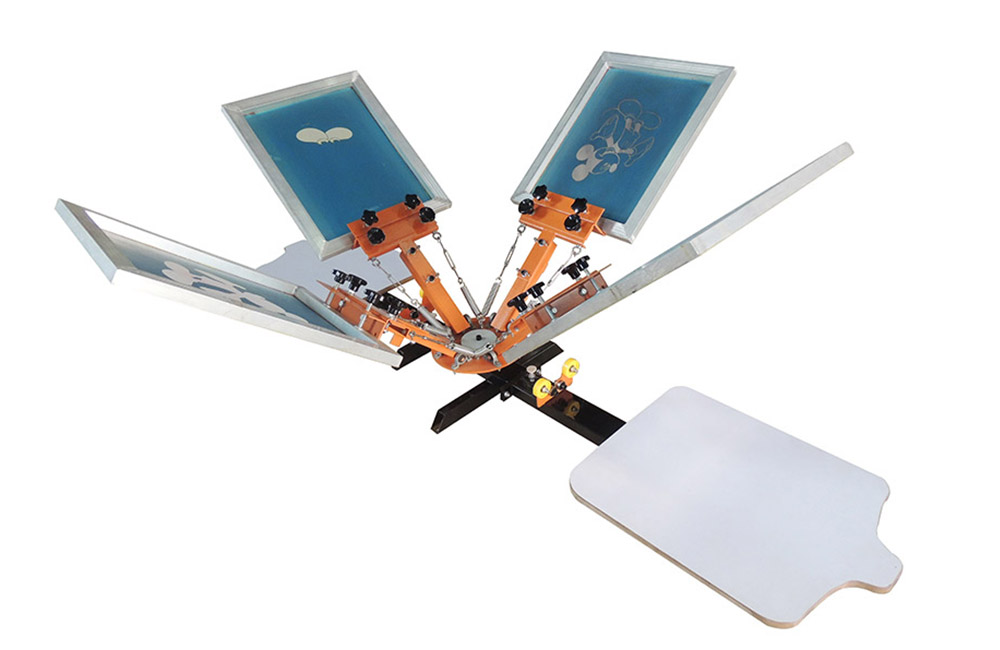

Silk screen printing is a popular method for creating high-quality prints on various surfaces, such as fabric, paper, and plastic. To maximize productivity in a silk screen printing operation, having an efficient workflow is essential. One way to achieve this is by using a 2 station silk screen printing press.

A 2 station silk screen printing press is a versatile piece of equipment that allows for faster printing and increased output. With two stations, operators can load and unload materials on one station while printing on the other, reducing downtime and increasing efficiency. This setup is ideal for small to medium-sized printing jobs that require quick turnaround times.

One of the key benefits of using a 2 station silk screen printing press is the ability to streamline the printing process. By having two stations, operators can work on multiple tasks simultaneously, such as setting up the next print job while the current job is running. This helps to reduce idle time and keep the press running at maximum capacity.

In addition to improving efficiency, a 2 station silk screen printing press also allows for greater flexibility in printing. Operators can easily switch between different print jobs without having to reconfigure the press, saving time and effort. This is especially useful for businesses that handle a variety of printing projects with different requirements.

Another advantage of using a 2 station silk screen printing press is the ability to achieve consistent and precise prints. With two stations, operators can ensure that each print is aligned correctly and that the ink coverage is uniform across the entire surface. This helps to maintain the quality of the prints and reduce waste due to misprints.

To further enhance productivity with a 2 station silk screen printing press, it is important to optimize the workflow. This includes organizing the work area for easy access to materials and tools, as well as implementing efficient printing techniques. Operators should also be trained on how to operate the press effectively to minimize errors and maximize output.

Regular maintenance and cleaning of the press are also crucial for ensuring smooth operation and prolonging its lifespan. This includes regularly lubricating moving parts, checking for wear and tear, and cleaning the screens and squeegees to prevent ink buildup. By keeping the press in good condition, operators can avoid downtime due to equipment failure and maintain a consistent workflow.

In conclusion, a 2 station silk screen printing press is a valuable tool for maximizing productivity in a printing operation. By utilizing its dual stations, operators can work more efficiently, achieve consistent prints, and handle a variety of printing projects with ease. With proper maintenance and workflow optimization, businesses can make the most of their 2 station silk screen printing press and increase their overall output.

Pre: Beginner-Friendly Screen Printing Machines: Features to Look For

Next: Small Screen Printing Machines: Affordable Options for Startups

Tags: