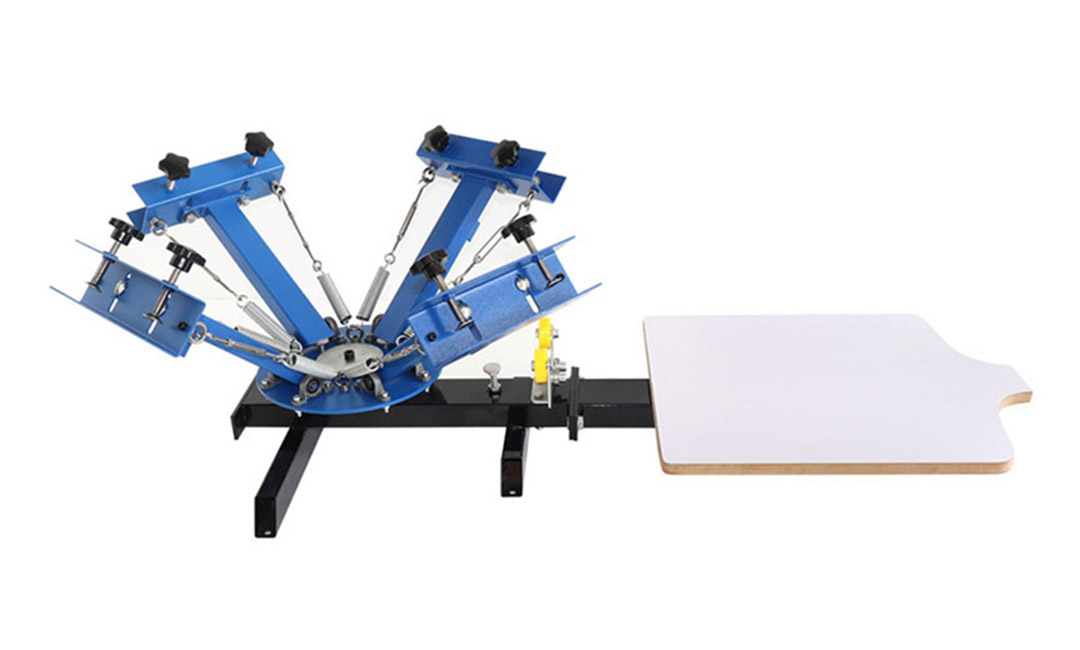

DIY T-Shirt Printing: Mastering the 4 Color 1 Station Screen Printing Process

Choosing the Right Materials

Screen printing is a popular method for creating custom t-shirts, as it allows for vibrant colors and durable prints. One of the most common screen printing setups is the 4 color 1 station press, which is perfect for beginners and small-scale projects. However, in order to achieve professional results, it is important to choose the right materials for the job.

The first step in the screen printing process is selecting the right screens. Screens are made of a mesh material stretched over a frame, and they are used to transfer the ink onto the t-shirt. When choosing screens for your 4 color 1 station press, it is important to consider the mesh count. A higher mesh count will produce finer details and smoother prints, while a lower mesh count is better for bold designs with thicker ink deposits.

Next, you will need to choose the right inks for your project. There are two main types of inks used in screen printing: water-based and plastisol. Water-based inks are environmentally friendly and produce a soft hand feel, while plastisol inks are more durable and vibrant. When using a 4 color 1 station press, it is important to choose inks that are compatible with the mesh count of your screens and that will work well with the type of fabric you are printing on.

In addition to screens and inks, you will also need squeegees for your screen printing setup. Squeegees are used to push the ink through the screen and onto the t-shirt. When choosing squeegees for your 4 color 1 station press, it is important to consider the durometer, or hardness, of the blade. A softer blade will deposit more ink onto the fabric, while a harder blade will produce a thinner layer of ink. It is also important to choose squeegees that are the right size for your screens, as using a squeegee that is too small can result in uneven prints.

Finally, you will need to choose the right t-shirts for your screen printing project. When selecting t-shirts, it is important to consider the fabric content, weight, and color. Different fabrics will react differently to the ink, so it is important to choose t-shirts that are compatible with the type of ink you are using. Additionally, lighter colored t-shirts will require a white underbase to ensure that the colors are vibrant and opaque.

In conclusion, choosing the right materials is essential for mastering the 4 color 1 station screen printing process. By selecting the right screens, inks, squeegees, and t-shirts for your project, you can achieve professional results and create custom t-shirts that are vibrant and durable. With the right materials and a little practice, you can become a master of DIY t-shirt printing with your 4 color 1 station press.

Pre: Is Riley Hopkins 150 1 Color 1 Station Worth the Investment?

Next: Maintenance Tips for a Long-Lasting 4 Color 1 Station Screen Printing Machine

Tags: