Comprehensive Guide to 4 Colour 1 Station Screen Printing Machine

Benefits of Using a 4 Colour 1 Station Screen Printing Machine

Screen printing is a popular method of printing that has been used for decades to create high-quality prints on various surfaces. One of the key components of screen printing is the screen printing machine, which is used to transfer ink onto the desired surface. One type of screen printing machine that is commonly used is the 4 colour 1 station screen printing machine. In this article, we will discuss the benefits of using a 4 colour 1 station screen printing machine.

One of the main benefits of using a 4 colour 1 station screen printing machine is its versatility. This type of machine allows you to print designs with up to 4 different colours in one pass. This means that you can create more complex and colourful designs without having to go through multiple printing processes. This can save you time and money, as you will not have to set up and clean multiple screens for each colour.

Another benefit of using a 4 colour 1 station screen printing machine is its efficiency. With this type of machine, you can print multiple colours at once, which can significantly reduce the time it takes to complete a printing job. This can be especially useful for businesses that have tight deadlines or need to produce large quantities of prints in a short amount of time.

In addition to its versatility and efficiency, a 4 colour 1 station screen printing machine is also easy to use. These machines are designed to be user-friendly, with simple controls and easy-to-follow instructions. This makes them ideal for beginners or small businesses that may not have a lot of experience with screen printing. With a 4 colour 1 station screen printing machine, you can start printing high-quality designs right away without having to spend a lot of time learning how to use the machine.

Furthermore, using a 4 colour 1 station screen printing machine can help you save money in the long run. These machines are typically more affordable than larger, multi-colour machines, making them a cost-effective option for businesses on a budget. Additionally, because you can print multiple colours at once, you can reduce the amount of ink and materials you need to complete a job, further saving you money in the long term.

Overall, a 4 colour 1 station screen printing machine is a versatile, efficient, and cost-effective option for businesses looking to create high-quality prints with multiple colours. Whether you are a beginner looking to get started in screen printing or a seasoned professional looking to streamline your printing process, a 4 colour 1 station screen printing machine can help you achieve your goals. With its ease of use, versatility, and cost-effectiveness, this type of machine is a valuable tool for any business looking to create stunning prints with multiple colours.

Step-by-Step Guide on How to Set Up and Use a 4 Colour 1 Station Screen Printing Machine

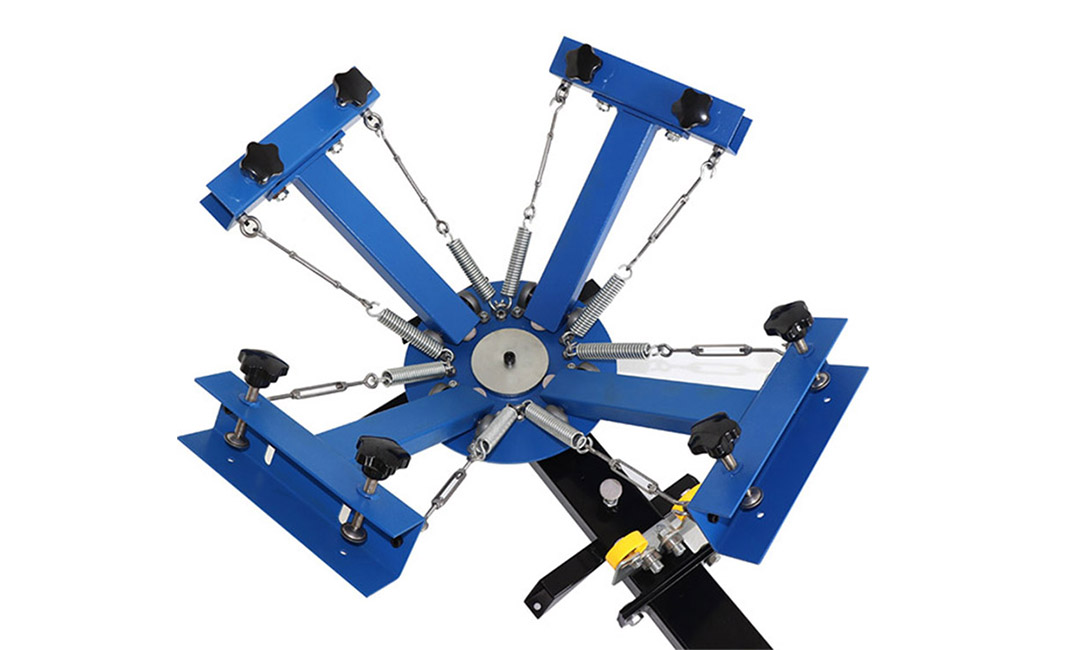

Screen printing is a popular method of printing designs onto various surfaces, such as t-shirts, posters, and bags. One of the most common types of screen printing machines is the 4 colour 1 station screen printing machine. This machine allows you to print designs with up to four different colours in one pass. In this comprehensive guide, we will walk you through the step-by-step process of setting up and using a 4 colour 1 station screen printing machine.

First and foremost, it is important to ensure that you have all the necessary equipment and supplies before you begin. This includes the screen printing machine itself, screens, squeegees, inks, and the items you will be printing on. Once you have gathered all your materials, you can begin setting up the machine.

The first step in setting up a 4 colour 1 station screen printing machine is to assemble the machine according to the manufacturer’s instructions. This typically involves attaching the arms and pallets to the base of the machine. Once the machine is assembled, you will need to attach the screens to the machine. Each screen corresponds to a different colour in your design, so make sure to attach the screens in the correct order.

Next, you will need to prepare your design for printing. This involves creating a stencil of your design on each screen. This stencil will allow the ink to pass through onto the item you are printing on. Once the stencils are ready, you can attach them to the screens using screen printing tape.

After the screens are attached, it is time to set up the ink. Place the ink of each colour in its corresponding spot on the machine. Make sure to adjust the ink levels and squeegee pressure to achieve the desired print quality.

Once everything is set up, you can begin printing. Place the item you are printing on the pallet and lower the screen onto the item. Use the squeegee to spread the ink across the screen, transferring the design onto the item. Repeat this process for each colour in your design, making sure to align the screens correctly each time.

After you have finished printing, it is important to clean the screens and machine thoroughly to prevent the ink from drying and clogging the screens. Use a screen cleaning solution and a brush to remove any excess ink from the screens.

In conclusion, a 4 colour 1 station screen printing machine is a versatile tool for printing designs with multiple colours. By following this step-by-step guide, you can set up and use a 4 colour 1 station screen printing machine with ease. With practice and patience, you can create professional-quality prints on a variety of surfaces.

Common Mistakes to Avoid When Using a 4 Colour 1 Station Screen Printing Machine

Screen printing is a popular method of printing designs onto various surfaces, such as t-shirts, posters, and bags. One of the most common types of screen printing machines is the 4 colour 1 station screen printing machine. This machine allows users to print designs with up to four different colors in one pass. While this machine can be a great tool for creating high-quality prints, there are some common mistakes that users should avoid to ensure the best results.

One common mistake that users make when using a 4 colour 1 station screen printing machine is not properly aligning the screens. Proper alignment is crucial for ensuring that each color in the design lines up correctly on the final print. To avoid this mistake, users should take the time to carefully align each screen before starting the printing process. This may require adjusting the screens multiple times to ensure that they are perfectly aligned.

Another common mistake is using the wrong type of ink for the job. Different types of inks are designed for different surfaces and applications. Using the wrong ink can result in poor adhesion, bleeding, or fading of the design. Before starting a print job, users should make sure they are using the correct type of ink for the material they are printing on.

Improperly cleaning the screens is another common mistake that can lead to poor print quality. Over time, ink can build up on the screens, causing clogs and smudges in the final print. To avoid this, users should regularly clean their screens with a screen cleaner and a soft brush. This will help to remove any built-up ink and ensure that the screens are clear and ready for printing.

Not properly curing the prints is another common mistake that can result in poor durability and washability of the design. Curing the prints involves applying heat to the design to set the ink and ensure that it adheres properly to the material. Users should follow the manufacturer’s instructions for curing times and temperatures to ensure that the prints are properly cured and will last for a long time.

Finally, rushing the printing process is a common mistake that can lead to errors and poor print quality. Users should take their time when setting up the machine, aligning the screens, and printing the designs. Rushing through the process can result in misaligned prints, smudges, and other errors that can ruin the final product. Taking the time to properly set up and execute each print job will result in higher quality prints and a more professional-looking final product.

In conclusion, there are several common mistakes that users should avoid when using a 4 colour 1 station screen printing machine. By properly aligning the screens, using the correct type of ink, cleaning the screens regularly, curing the prints properly, and taking their time during the printing process, users can ensure that they achieve the best results possible. By following these tips, users can create high-quality prints that will impress their customers and stand the test of time.

Pre: Step-by-Step Setup Guide for 4 Color 1 Station Press

Next: Choosing the Right 4 Color 1 Station Screen Printing Equipment for Your Workshop

Tags: