Comparing 2 Station vs. 4 Station Silk Screen Printing Presses

Pros and Cons of Using a 2 Station Silk Screen Printing Press

Silk screen printing is a popular method used to transfer designs onto various surfaces, such as fabric, paper, and plastic. When it comes to silk screen printing presses, there are two main types: 2 station and 4 station presses. Each type has its own set of pros and cons, which we will explore in this article.

Let’s start by looking at the pros of using a 2 station silk screen printing press. One of the main advantages of a 2 station press is its compact size. This makes it ideal for small businesses or hobbyists who have limited space in their workspace. Additionally, a 2 station press is typically more affordable than a 4 station press, making it a cost-effective option for those on a budget.

Another benefit of a 2 station press is its simplicity and ease of use. With only two stations, it is easier to set up and operate, making it a great option for beginners or those who are new to silk screen printing. Additionally, a 2 station press is easier to maintain and clean, as there are fewer moving parts and components to worry about.

However, there are also some drawbacks to using a 2 station silk screen printing press. One of the main disadvantages is its limited production capacity. With only two stations, you can only print two colors at a time, which can be a limiting factor for those who need to print more complex designs with multiple colors.

Another downside of a 2 station press is its slower production speed. Since you can only print two colors at a time, it can take longer to complete a print run compared to a 4 station press. This can be a significant drawback for businesses that have high volume printing needs or tight deadlines to meet.

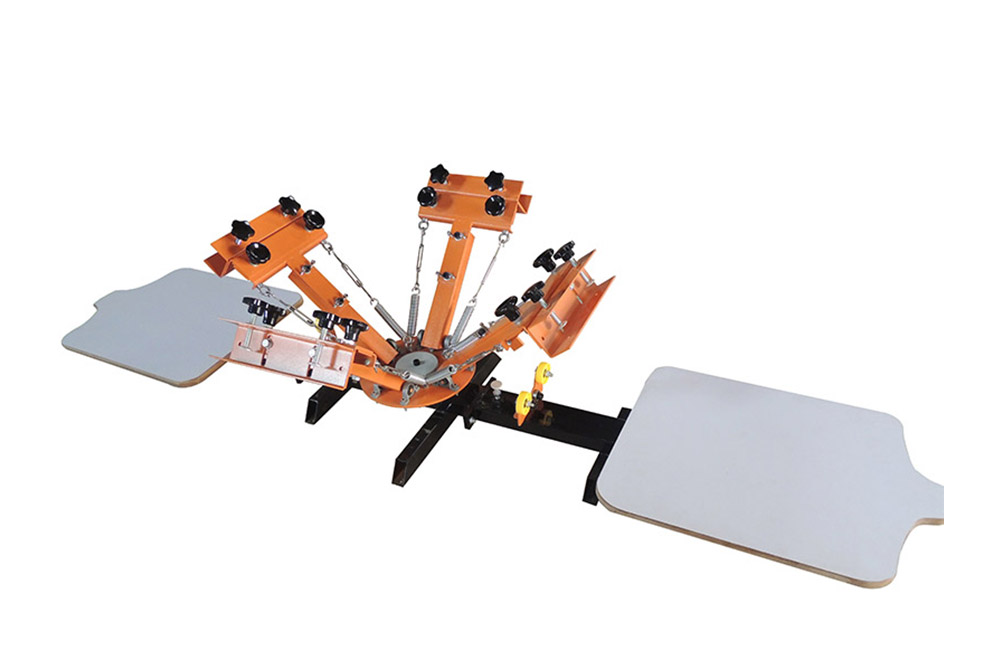

In contrast, let’s now consider the pros and cons of using a 4 station silk screen printing press. One of the main advantages of a 4 station press is its higher production capacity. With four stations, you can print up to four colors at a time, allowing you to create more complex and colorful designs with ease.

Additionally, a 4 station press offers faster production speeds compared to a 2 station press. With the ability to print more colors simultaneously, you can complete print runs more quickly and efficiently, making it a great option for businesses with high volume printing needs.

However, there are also some drawbacks to using a 4 station silk screen printing press. One of the main disadvantages is its larger size and higher cost. A 4 station press takes up more space and is typically more expensive than a 2 station press, which can be a limiting factor for small businesses or hobbyists with limited budgets and workspace.

Another downside of a 4 station press is its complexity and higher maintenance requirements. With more stations and moving parts, a 4 station press can be more difficult to set up and operate, requiring more time and effort to maintain and clean.

In conclusion, both 2 station and 4 station silk screen printing presses have their own set of pros and cons. The choice between the two will ultimately depend on your specific needs and preferences. If you have limited space and budget, a 2 station press may be the best option for you. However, if you have high volume printing needs and require more colors and faster production speeds, a 4 station press may be the better choice. Ultimately, it is important to carefully consider your requirements and weigh the pros and cons of each type of press before making a decision.

Pre: 4 Color Screen Printing Press vs. 6 Color: Which One Do You Need?

Next: Top 5 Small Screen Printing Machines for Home and Business Use

Tags: