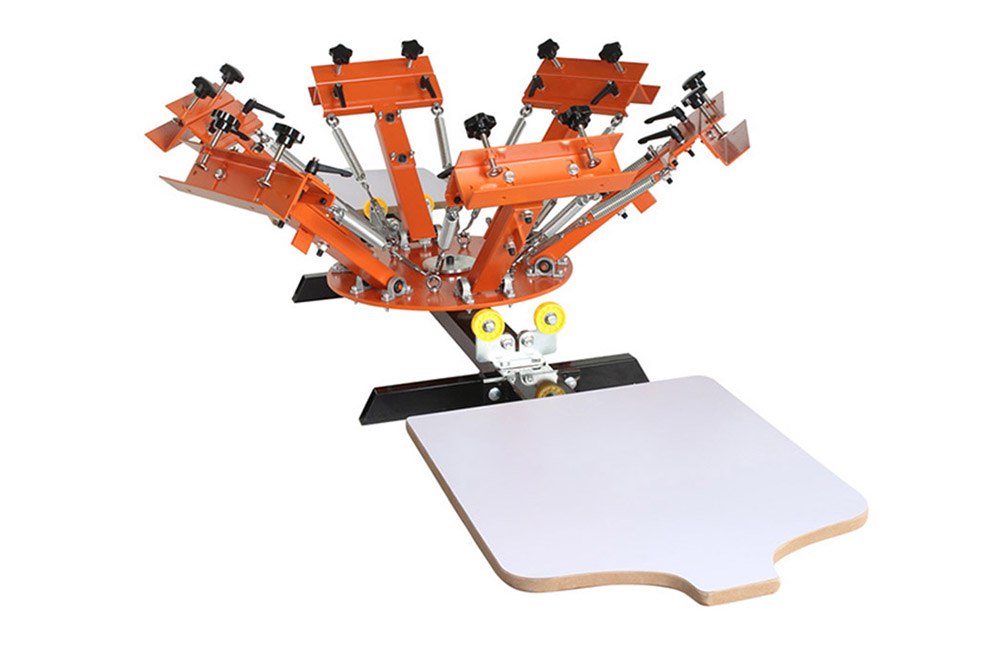

Common Mistakes to Avoid When Using a 4 Color Screen Printing Press

Choosing the Wrong Mesh Count for the Design

Common Mistakes to Avoid When Using a 4 Color Screen Printing Press

When it comes to screen printing, there are several common mistakes that beginners often make. One of the most crucial aspects of screen printing is choosing the right mesh count for your design. The mesh count refers to the number of threads per inch in the screen, and it plays a significant role in determining the level of detail and clarity in your print.

One common mistake that beginners make is using a mesh count that is too low for their design. A low mesh count means that there are fewer threads per inch, resulting in larger holes in the screen. This can lead to a loss of detail in your print, as the ink may bleed through the larger holes and create a blurry or smudged image. It is essential to choose a mesh count that is appropriate for the level of detail you want to achieve in your design.

On the other hand, using a mesh count that is too high can also be problematic. A high mesh count means that there are more threads per inch, resulting in smaller holes in the screen. While this may seem like a good thing for achieving fine detail, it can actually make it more challenging to push the ink through the screen. This can lead to uneven ink distribution and a lack of clarity in your print. It is crucial to find the right balance between detail and ink flow when choosing a mesh count.

Another mistake to avoid is not considering the type of ink you will be using. Different inks have different viscosities, or thicknesses, which can affect how well they pass through the screen. Thicker inks may require a lower mesh count to ensure proper ink flow, while thinner inks may require a higher mesh count to prevent bleeding. It is essential to test your ink on different mesh counts to determine the best combination for your specific design.

Additionally, not properly preparing the screen before printing can lead to issues with the mesh count. It is crucial to clean and degrease the screen thoroughly to ensure that the ink adheres properly. Any dirt or residue on the screen can clog the mesh and prevent the ink from passing through evenly. Taking the time to properly prepare the screen can help prevent issues with ink flow and ensure a clean and crisp print.

Lastly, not properly maintaining and storing your screens can also affect the mesh count. Screens can become stretched or damaged over time, which can alter the tension of the mesh and affect the print quality. It is essential to store screens flat or rolled to prevent any stretching or warping. Regularly inspecting and replacing screens when necessary can help maintain the integrity of the mesh count and ensure consistent print quality.

In conclusion, choosing the wrong mesh count for your design is a common mistake that beginners often make when using a 4 color screen printing press. It is crucial to find the right balance between detail and ink flow by selecting a mesh count that is appropriate for your design and considering the type of ink you will be using. Properly preparing the screen, maintaining and storing screens, and regularly inspecting and replacing them when necessary are also essential steps to ensure consistent print quality. By avoiding these common mistakes, you can achieve professional-looking prints with your 4 color screen printing press.

Pre: Best Budget-Friendly Small Screen Printing Machines in 2024

Next: Understanding Platen Size and How It Affects Screen Printing Results

Tags: