Choosing the Right Exposure Unit for Perfect Screen Prints

Benefits of Using LED Exposure Units for Screen Printing

Screen printing is a popular method of transferring designs onto various surfaces, such as fabric, paper, and plastic. One of the key components of the screen printing process is the exposure unit, which is used to transfer the design onto the screen. There are various types of exposure units available on the market, but one of the most popular options is the LED exposure unit.

LED exposure units offer a number of benefits that make them a preferred choice for many screen printers. One of the main advantages of using an LED exposure unit is its energy efficiency. LED lights consume less energy compared to traditional fluorescent tubes, making them a more cost-effective option in the long run. This can result in significant savings on electricity bills for screen printing businesses.

In addition to being energy efficient, LED exposure units also offer consistent and even light distribution. This is crucial for achieving high-quality screen prints, as uneven exposure can result in blurred or distorted designs. LED lights provide a uniform light source that ensures accurate and precise exposure, resulting in crisp and clear prints every time.

Another benefit of using LED exposure units is their durability and longevity. LED lights have a longer lifespan compared to traditional fluorescent tubes, which means they require less frequent replacement. This can save screen printers time and money on maintenance and replacement costs, allowing them to focus on their craft without interruptions.

LED exposure units also offer faster exposure times compared to traditional units. LED lights reach full brightness almost instantly, allowing for quicker exposure of screens. This can help screen printers increase their productivity and turnaround times, as they can expose screens more quickly and efficiently.

Furthermore, LED exposure units are environmentally friendly. LED lights do not contain harmful chemicals such as mercury, which are commonly found in fluorescent tubes. This makes LED exposure units a safer and more sustainable option for screen printing businesses looking to reduce their environmental impact.

Overall, LED exposure units offer a range of benefits that make them an ideal choice for screen printers looking to achieve perfect screen prints. From energy efficiency and consistent light distribution to durability and faster exposure times, LED exposure units provide a reliable and cost-effective solution for businesses of all sizes.

In conclusion, choosing the right exposure unit is essential for achieving high-quality screen prints. LED exposure units offer a number of advantages that make them a popular choice among screen printers. With their energy efficiency, consistent light distribution, durability, and fast exposure times, LED exposure units provide a reliable and cost-effective solution for businesses looking to produce perfect screen prints every time.

Factors to Consider When Selecting an Exposure Unit for Screen Printing

Screen printing is a popular method of printing that involves transferring ink onto a substrate through a mesh screen. One of the key components of the screen printing process is the exposure unit, which is used to create the stencil on the screen. Choosing the right exposure unit is crucial for achieving high-quality screen prints. There are several factors to consider when selecting an exposure unit for screen printing.

One of the most important factors to consider when choosing an exposure unit is the type of screen printing you will be doing. Different types of exposure units are designed for different types of screen printing. For example, if you will be doing high-volume production runs, you will need an exposure unit that can handle large screens and produce consistent results. On the other hand, if you will be doing small runs or custom prints, a smaller exposure unit may be sufficient.

Another factor to consider when selecting an exposure unit is the size of the screens you will be using. Exposure units come in a variety of sizes, so it is important to choose one that can accommodate the size of the screens you will be using. If you will be using screens of different sizes, you may need to invest in an exposure unit with adjustable settings.

The type of light source used in the exposure unit is also an important factor to consider. Exposure units typically use either UV or LED lights to expose the screens. UV lights are more traditional and are known for producing high-quality results. However, LED lights are becoming increasingly popular due to their energy efficiency and longer lifespan. Consider your budget and the type of prints you will be producing when choosing between UV and LED lights.

It is also important to consider the exposure time of the unit. The exposure time refers to the amount of time the screen is exposed to light in order to create the stencil. Exposure units with shorter exposure times are generally more efficient and can help increase productivity. However, shorter exposure times may require more precise timing and may not be suitable for beginners.

When selecting an exposure unit, it is important to consider the overall build quality and durability of the unit. Exposure units are an investment, so it is important to choose one that is built to last. Look for exposure units made from high-quality materials that are designed to withstand the rigors of regular use.

In conclusion, choosing the right exposure unit is essential for achieving perfect screen prints. Consider factors such as the type of screen printing you will be doing, the size of the screens you will be using, the type of light source, exposure time, and build quality when selecting an exposure unit. By carefully considering these factors, you can ensure that you choose an exposure unit that meets your needs and helps you achieve high-quality screen prints.

Tips for Achieving Consistent and Accurate Exposures with Your Exposure Unit

Screen printing is a popular method of printing that involves transferring ink onto a substrate through a mesh screen. One of the key components in the screen printing process is the exposure unit, which is used to create the stencil on the screen. The exposure unit exposes the emulsion-coated screen to light, hardening the emulsion in areas where the design is to be printed. Choosing the right exposure unit is crucial for achieving consistent and accurate exposures, which are essential for producing high-quality screen prints.

When selecting an exposure unit, there are several factors to consider. One of the most important factors is the type of light source used in the unit. Exposure units typically use either UV or LED lights. UV lights are traditional and have been used in exposure units for many years. They provide a consistent and even exposure, making them a popular choice among screen printers. LED lights, on the other hand, are a newer technology that is becoming increasingly popular. LED lights are energy-efficient and have a longer lifespan than UV lights. They also produce less heat, which can be beneficial for certain types of emulsions.

Another factor to consider when choosing an exposure unit is the size of the unit. Exposure units come in a variety of sizes, ranging from small tabletop units to large industrial units. The size of the unit you choose will depend on the size of the screens you will be exposing. If you are working with small screens, a tabletop unit may be sufficient. However, if you are working with larger screens or need to expose multiple screens at once, a larger unit may be necessary.

In addition to the light source and size of the unit, it is also important to consider the features and capabilities of the unit. Some exposure units come with built-in timers and light meters, which can help you achieve consistent exposures. Others may have vacuum systems to ensure that the screen is held flat against the glass during exposure. Some units also have adjustable height settings, which can be useful for exposing screens of different thicknesses.

Once you have selected an exposure unit, it is important to properly calibrate and maintain the unit to ensure consistent and accurate exposures. Calibration involves determining the correct exposure time for your specific emulsion and mesh count. This can be done through trial and error, or by using a step wedge test. Maintaining the unit involves regularly cleaning the glass and light source to ensure that they are free of dust and debris, which can affect the quality of the exposure.

In conclusion, choosing the right exposure unit is essential for achieving consistent and accurate exposures in screen printing. Consider factors such as the type of light source, size of the unit, and features and capabilities when selecting an exposure unit. Proper calibration and maintenance of the unit are also important for achieving high-quality screen prints. By taking the time to choose the right exposure unit and properly calibrating and maintaining it, you can ensure that your screen prints are of the highest quality.

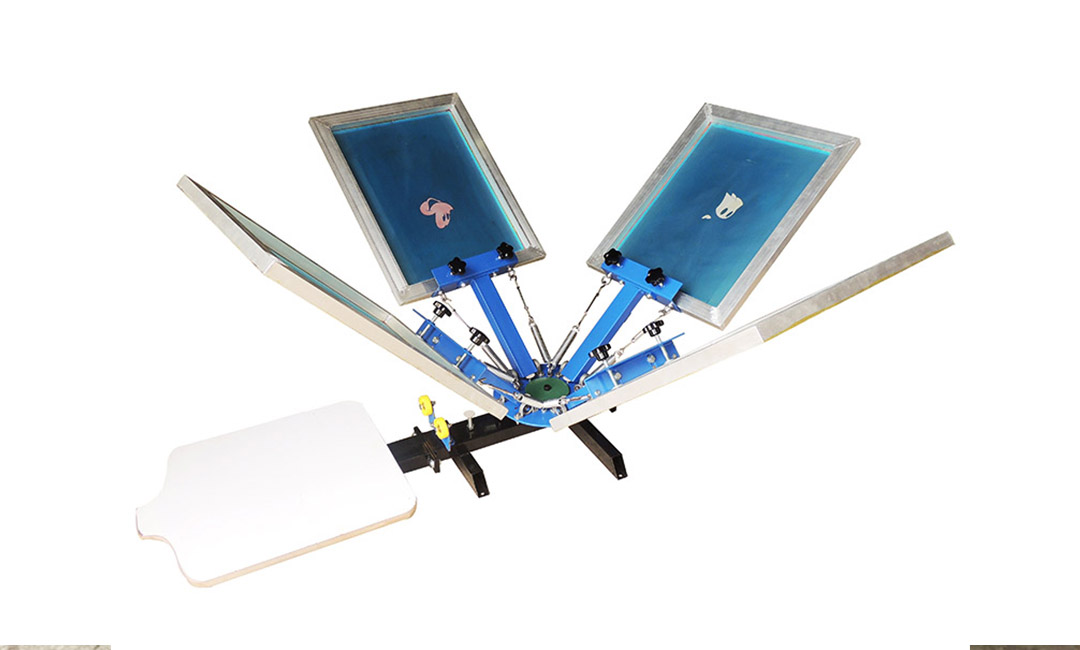

Pre: Everything You Need to Know About Operating a Riley Hopkins 4 Color Press

Next: How Tabletop Silk Screen Printers Enhance Your T-Shirt Business

Tags: