Best Practices for Using Micro Registration in 4 Color 1 Station Press

Benefits of Micro Registration in 4 Color 1 Station Press

Micro registration is a crucial technique in the world of screen printing, especially when it comes to achieving precise and accurate prints. In a 4 color 1 station press, micro registration allows for the alignment of multiple screens to ensure that each color is printed in the correct position. This not only improves the overall quality of the print but also reduces the margin of error, resulting in a more professional-looking final product.

One of the key benefits of using micro registration in a 4 color 1 station press is the ability to achieve tight registration. Tight registration refers to the alignment of different colors on a print so that they appear seamless and without any overlap or gaps. This is particularly important when printing intricate designs or images with multiple colors. By using micro registration, printers can make small adjustments to the position of each screen to ensure that the colors line up perfectly, resulting in a crisp and clean print.

Another advantage of micro registration is the ability to easily make adjustments during the printing process. With traditional screen printing methods, once the screens are set up and locked in place, any misalignment or errors can be difficult to correct. However, with micro registration, printers can make small adjustments to the position of each screen as needed, allowing for quick and precise corrections without having to start the entire printing process over again. This not only saves time but also reduces waste and improves efficiency in the printing process.

In addition to achieving tight registration and making adjustments on the fly, micro registration also allows for greater consistency in prints. By ensuring that each color is printed in the exact same position on every print, printers can create a uniform and professional-looking final product. This is particularly important for businesses that require large quantities of prints, as it helps maintain brand consistency and quality across all products.

Furthermore, using micro registration in a 4 color 1 station press can help reduce the risk of misprints and errors. By aligning the screens accurately and making precise adjustments, printers can minimize the chances of colors bleeding into each other or prints being off-center. This not only improves the overall quality of the prints but also reduces the need for reprints, saving time and money in the long run.

Overall, incorporating micro registration into the printing process of a 4 color 1 station press can greatly improve the quality, efficiency, and consistency of prints. By achieving tight registration, making adjustments on the fly, maintaining consistency, and reducing the risk of errors, printers can create professional-looking prints that meet the highest standards. Whether printing intricate designs or large quantities of products, micro registration is a valuable technique that can help elevate the quality of screen printing projects.

Tips for Achieving Precise Registration with Micro Registration

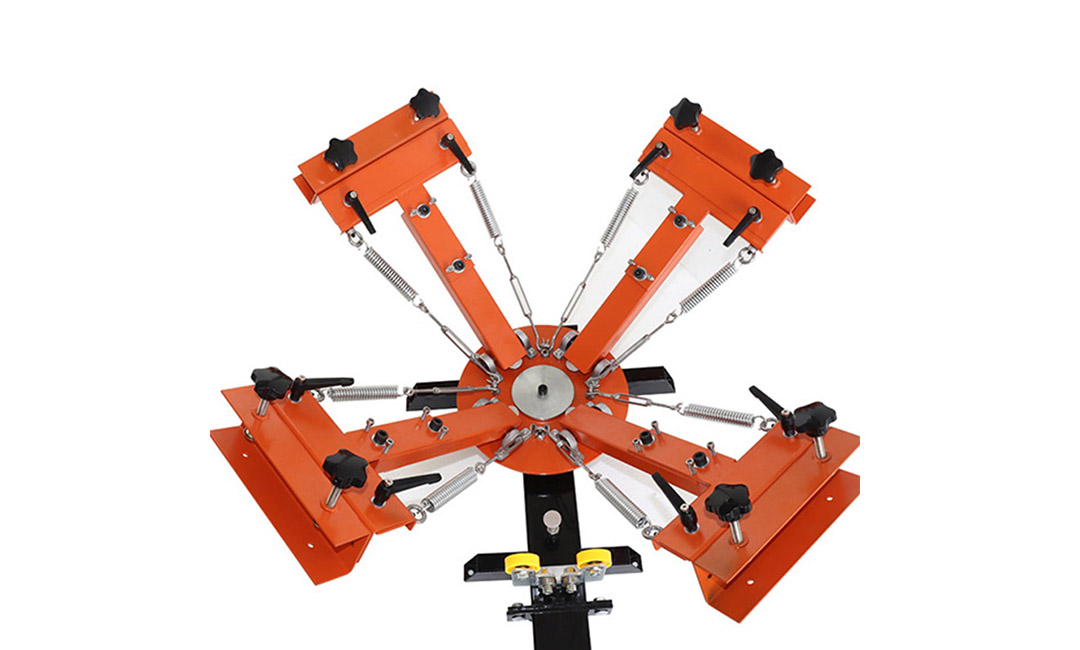

Achieving precise registration in screen printing is crucial for producing high-quality prints. One way to improve registration accuracy is by using a micro registration system on a 4 color 1 station press. Micro registration allows for fine adjustments to be made to each color plate, ensuring that the colors align perfectly on the final print. In this article, we will discuss some best practices for using micro registration to achieve precise registration on a 4 color 1 station press.

When setting up your 4 color 1 station press for printing, it is important to start by properly aligning the screen frames. Make sure that each screen is securely fastened to the press and that the frames are level and square. This will provide a solid foundation for achieving accurate registration.

Once the screens are in place, it is time to adjust the micro registration system. Most micro registration systems have knobs or screws that allow for precise adjustments to be made in both the horizontal and vertical directions. Start by loosening the locking mechanisms on the micro registration system and then make small adjustments to each color plate until the registration is perfect.

When making adjustments to the micro registration system, it is important to take your time and make small, incremental changes. This will help prevent overcorrection and ensure that the registration remains accurate. It may take some trial and error to get the registration just right, but patience and attention to detail will pay off in the final print.

Another best practice for using micro registration in a 4 color 1 station press is to use registration marks on your screens. Registration marks are small, precise marks that are printed on each color plate and are used to align the screens during setup. By using registration marks, you can quickly and easily align the screens and make adjustments to the micro registration system as needed.

In addition to using registration marks, it is also helpful to use a registration template when setting up your screens. A registration template is a tool that is placed on the press bed and provides a guide for aligning the screens. By using a registration template, you can ensure that the screens are positioned correctly and that the registration is accurate.

Finally, it is important to regularly check and adjust the micro registration system throughout the printing process. As the press is used, vibrations and other factors can cause the registration to shift slightly. By periodically checking and adjusting the micro registration system, you can maintain precise registration and ensure that each print is of the highest quality.

In conclusion, using a micro registration system on a 4 color 1 station press is a great way to achieve precise registration in screen printing. By following these best practices, including properly aligning the screens, making small adjustments to the micro registration system, using registration marks and templates, and regularly checking and adjusting the registration, you can ensure that your prints are consistently accurate and high-quality. With attention to detail and a commitment to precision, you can achieve perfect registration on your 4 color 1 station press.

Common Mistakes to Avoid When Using Micro Registration in 4 Color 1 Station Press

Micro registration is a crucial technique in the world of screen printing, especially when working with a 4 color 1 station press. This process allows for precise alignment of each color layer, resulting in crisp and vibrant prints. However, there are common mistakes that can occur when using micro registration that can hinder the quality of your prints. In this article, we will discuss some of these mistakes and provide tips on how to avoid them.

One of the most common mistakes when using micro registration is not properly calibrating the press before starting a print job. It is essential to ensure that the press is level and that the micro registration knobs are set to zero before beginning the registration process. Failing to do so can result in misaligned prints and wasted materials. To avoid this mistake, always take the time to calibrate your press before each print job.

Another mistake to avoid is not using the correct mesh count for each color layer. Different colors require different mesh counts to achieve optimal results. Using the wrong mesh count can lead to poor ink coverage and registration issues. Before starting a print job, make sure to determine the appropriate mesh count for each color layer and adjust accordingly.

Improperly tensioned screens can also cause registration issues when using micro registration. Screens that are too loose or too tight can result in misaligned prints and inconsistent ink coverage. To avoid this mistake, regularly check the tension of your screens and make adjustments as needed. Properly tensioned screens will ensure smooth and accurate registration.

Inadequate lighting in the printing area can also lead to registration errors. Poor lighting can make it difficult to see the registration marks and make precise adjustments. To avoid this mistake, make sure to have adequate lighting in your printing area. Consider using a light table or additional lighting to ensure clear visibility of the registration marks.

Not taking the time to properly clean and maintain your press can also result in registration issues. Dust, dirt, and debris can build up on the press over time, causing misalignment and poor print quality. To avoid this mistake, regularly clean and maintain your press to ensure smooth operation and accurate registration.

Lastly, rushing through the registration process can lead to mistakes and errors. It is essential to take your time and make precise adjustments when using micro registration. Rushing through the process can result in misaligned prints and wasted materials. To avoid this mistake, be patient and methodical when registering each color layer.

In conclusion, using micro registration in a 4 color 1 station press can be a challenging but rewarding process. By avoiding common mistakes such as improper calibration, using the correct mesh count, maintaining proper screen tension, ensuring adequate lighting, cleaning and maintaining your press, and taking your time during the registration process, you can achieve crisp and vibrant prints with precise alignment. Remember to always pay attention to detail and be diligent in your approach to micro registration to achieve the best results.

Pre: Why 4 Color 1 Station Silk Screen Printing is Perfect for Small Businesses

Next: Exploring the Capabilities of Vevor Screen Printing Machine 4 Color 1 Station

Tags: