Best Practices for Home-Based Screen Printing with 4 Colour 1 Station

Choosing the Right Screen Printing Equipment for Home-Based Businesses

Screen printing is a popular method of printing designs onto various surfaces, such as t-shirts, posters, and other promotional items. For those looking to start a home-based screen printing business, choosing the right equipment is crucial to ensure success. One popular option for beginners is the 4 Colour 1 Station screen printing press, which allows for printing up to four colors at once on a single station.

When setting up a home-based screen printing business, it is important to consider the space available for equipment. The 4 Colour 1 Station press is a compact and versatile option that can easily fit into a small workspace. This press is also relatively easy to set up and operate, making it ideal for beginners who may not have experience with screen printing equipment.

In addition to the press itself, there are a few other essential pieces of equipment that are needed for home-based screen printing. These include screens, squeegees, inks, and a flash dryer. Screens are used to transfer the design onto the printing surface, while squeegees are used to push the ink through the screen. Inks come in a variety of colors and types, so it is important to choose the right ones for the job. A flash dryer is used to cure the ink and set the design onto the printing surface.

When choosing screens for the 4 Colour 1 Station press, it is important to consider the mesh count. The mesh count refers to the number of threads per inch on the screen, and a higher mesh count will result in a finer print. For beginners, a mesh count of around 110-160 is recommended, as it is versatile enough to work with a variety of designs and inks.

Squeegees are another important piece of equipment for screen printing. When choosing a squeegee, it is important to consider the hardness of the blade. A softer blade will deposit more ink onto the printing surface, while a harder blade will deposit less ink. For beginners, a medium hardness blade is recommended, as it provides a good balance between ink coverage and control.

Inks are available in a variety of types, including water-based, plastisol, and discharge inks. Water-based inks are environmentally friendly and easy to clean up, making them a popular choice for beginners. Plastisol inks are more durable and provide vibrant colors, but they require heat curing with a flash dryer. Discharge inks are used for printing on dark fabrics and require a chemical activator to remove the dye from the fabric before printing.

A flash dryer is an essential piece of equipment for curing the ink and setting the design onto the printing surface. When using a 4 Colour 1 Station press, it is important to choose a flash dryer that is compatible with the press and can accommodate the size of the designs being printed. It is also important to follow the manufacturer’s instructions for curing times and temperatures to ensure a successful print.

In conclusion, setting up a home-based screen printing business with a 4 Colour 1 Station press requires careful consideration of the equipment needed. By choosing the right screens, squeegees, inks, and flash dryer, beginners can create high-quality prints and build a successful business. With the right equipment and practice, home-based screen printing can be a rewarding and profitable venture.

Proper Setup and Maintenance of a 4 Colour 1 Station Screen Printing Press

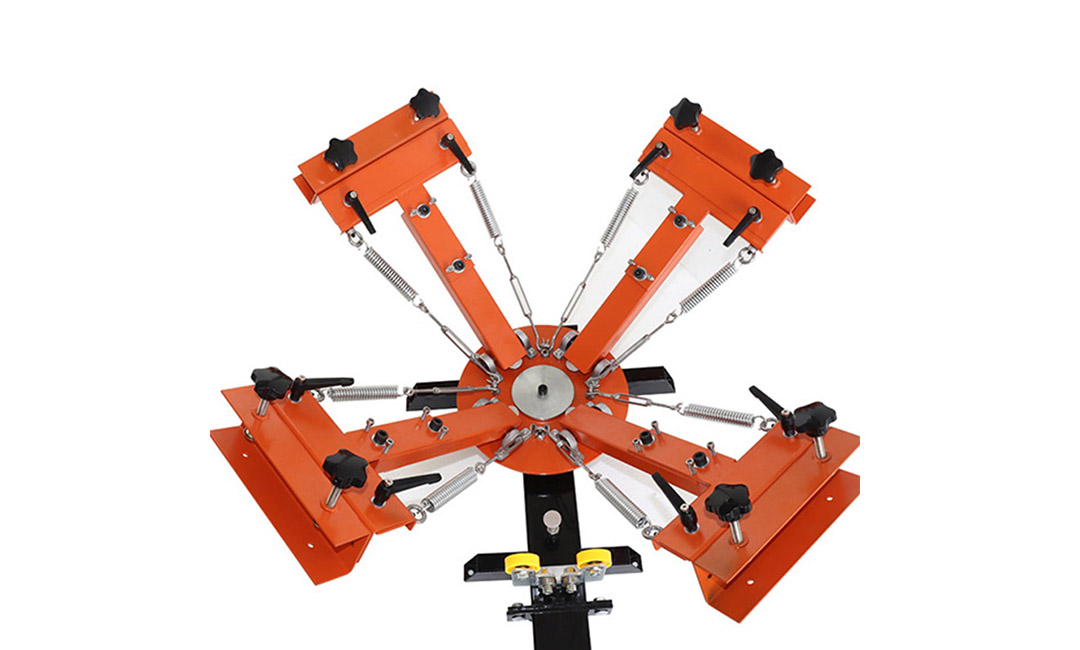

Screen printing is a popular method of printing designs onto various surfaces, including clothing, posters, and other materials. For those looking to start a home-based screen printing business, investing in a 4 Colour 1 Station screen printing press is a great option. This type of press allows for multiple colors to be printed onto a single item, making it ideal for creating vibrant and detailed designs. However, in order to ensure the best results, it is important to properly set up and maintain your screen printing press.

The first step in setting up your 4 Colour 1 Station screen printing press is to ensure that it is placed on a stable and level surface. This will help prevent any unwanted movement or shaking during the printing process, which can result in blurry or misaligned prints. Additionally, make sure that the press is positioned in a well-lit area with plenty of space to move around and access all of the necessary supplies.

Next, it is important to properly assemble the press according to the manufacturer’s instructions. This may involve attaching the arms, pallets, and screens to the base of the press. Take your time during this step to ensure that everything is securely in place and functioning properly. Once the press is assembled, it is important to adjust the off-contact distance for each color station. This distance refers to the space between the screen and the printing surface, and can be adjusted using the knobs or screws on the press. Proper off-contact distance is crucial for achieving clean and crisp prints, so be sure to take the time to adjust it correctly.

In addition to setting up your press, it is important to regularly maintain and clean it to ensure optimal performance. This includes regularly lubricating any moving parts, such as the arms and hinges, to prevent them from becoming stiff or stuck. It is also important to regularly clean the screens, pallets, and squeegees to prevent ink buildup and ensure that your prints are consistent and high-quality.

When it comes to printing with a 4 Colour 1 Station screen printing press, it is important to use high-quality inks and screens to achieve the best results. Additionally, be sure to properly register your screens to ensure that each color lines up correctly on the final print. This may involve using registration marks or a registration template to align the screens before printing.

Overall, proper setup and maintenance of your 4 Colour 1 Station screen printing press is essential for achieving high-quality prints and running a successful home-based screen printing business. By following these best practices, you can ensure that your press is functioning properly and producing professional-looking prints. So take the time to set up your press correctly, regularly maintain it, and use high-quality materials to achieve the best results. With a little bit of effort and attention to detail, you can create stunning prints that will impress your customers and help your business thrive.

Tips for Achieving High-Quality Prints on Various Garments at Home

Screen printing is a popular method for creating high-quality prints on various garments, and with the right equipment and techniques, it can be done successfully at home. One of the most common setups for home-based screen printing is the 4 colour 1 station press, which allows for printing multiple colors on a single garment. In this article, we will discuss some best practices for achieving high-quality prints using a 4 colour 1 station press at home.

First and foremost, it is important to properly set up your 4 colour 1 station press before starting the printing process. Make sure that the press is securely mounted to a stable surface and that all of the screens are aligned correctly. This will help ensure that your prints come out crisp and clean. Additionally, make sure that you have the right mesh count for your screens, as this will affect the quality of your prints.

When it comes to choosing the right inks for your screen printing project, it is important to use high-quality, opaque inks that are specifically designed for use on garments. These inks will provide vibrant colors and good coverage, resulting in professional-looking prints. It is also important to properly mix your inks before printing to ensure consistent color throughout your prints.

Another important factor to consider when screen printing at home is the type of garments you are printing on. Different fabrics require different printing techniques, so it is important to do some research and test prints on different types of garments before starting a large production run. Additionally, make sure to properly cure your prints after printing to ensure that they are wash-fast and durable.

In order to achieve high-quality prints with a 4 colour 1 station press, it is important to pay attention to detail during the printing process. Make sure that your screens are properly coated and exposed, and that you are using the right squeegee pressure and angle when printing. Additionally, make sure to properly register your screens to ensure that your colors line up correctly.

One of the most important aspects of achieving high-quality prints with a 4 colour 1 station press is practice. Screen printing is a skill that takes time to master, so don’t get discouraged if your first few prints don’t turn out perfectly. Keep practicing and experimenting with different techniques until you find what works best for you.

In conclusion, achieving high-quality prints with a 4 colour 1 station press at home is possible with the right equipment, techniques, and practice. By properly setting up your press, choosing the right inks and garments, paying attention to detail during the printing process, and practicing regularly, you can create professional-looking prints on a variety of garments. So roll up your sleeves, get your hands dirty, and start screen printing at home today!

Pre: How to Maintain Your 4 Color 1 Station Silk Screen Printing Equipment

Next: Why 4 Colour 1 Station Screen Printing Machines are Perfect for Startups

Tags: