5 Mistakes to Avoid with Beginner Screen Printing Machines

Proper Machine Setup

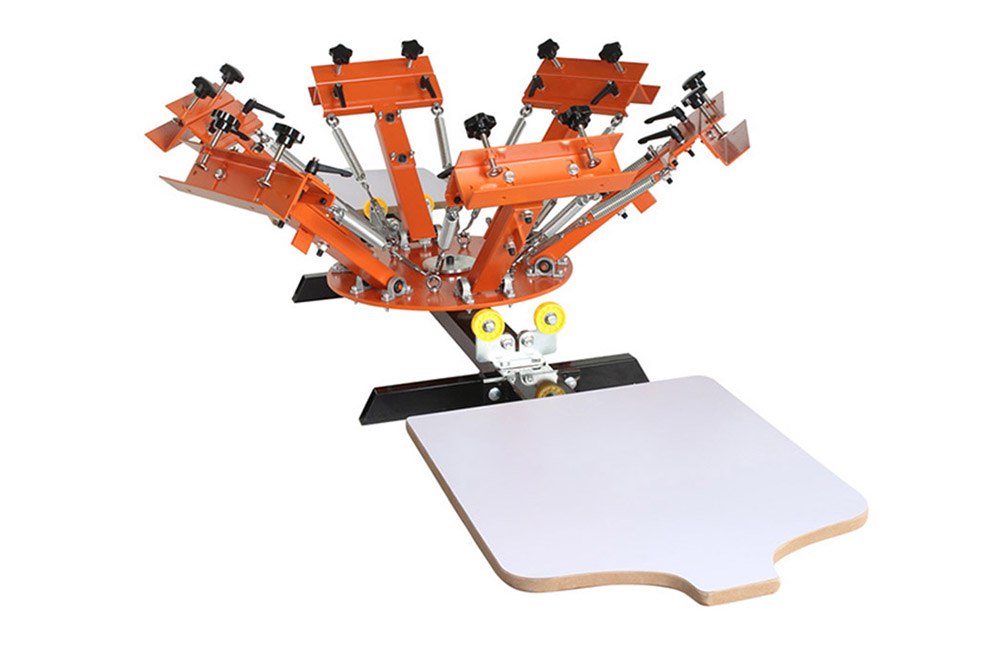

Screen printing is a popular method for creating high-quality prints on various surfaces, from t-shirts to posters. For beginners looking to get started with screen printing, investing in a beginner screen printing machine is a great first step. However, there are some common mistakes that beginners often make when setting up their machines. In this article, we will discuss five mistakes to avoid when setting up your beginner screen printing machine to ensure successful printing results.

The first mistake to avoid is not properly calibrating your machine. Calibration is essential for ensuring that your prints come out correctly and that the colors are accurate. Before starting any printing job, take the time to calibrate your machine according to the manufacturer’s instructions. This will help prevent any issues with alignment or color accuracy during the printing process.

Another common mistake is not properly cleaning your machine before each use. Screen printing machines can quickly accumulate dust, ink, and other debris, which can affect the quality of your prints. Before starting a new printing job, be sure to thoroughly clean your machine, including the screens, squeegees, and ink trays. This will help prevent any unwanted marks or smudges on your prints and ensure a clean and professional finish.

One of the most critical mistakes to avoid is using the wrong type of ink or emulsion for your screen printing machine. Different machines require specific types of ink and emulsion to produce high-quality prints. Using the wrong type of ink or emulsion can result in poor print quality, smudging, or even damage to your machine. Before starting any printing job, make sure you are using the correct ink and emulsion for your machine to achieve the best results.

Another common mistake is not properly adjusting the tension on your screens. Screen tension plays a crucial role in the printing process, as it affects the quality and consistency of your prints. If the tension on your screens is too loose or too tight, it can result in uneven prints, smudging, or even tearing of the screens. Before starting a new printing job, be sure to check and adjust the tension on your screens according to the manufacturer’s guidelines to ensure optimal printing results.

Finally, one of the most common mistakes beginners make is not properly curing their prints after the printing process. Curing is the final step in the screen printing process, where the ink is heated to ensure it bonds properly to the surface. If prints are not properly cured, the ink can wash out or fade over time, resulting in poor print quality. To avoid this mistake, be sure to follow the manufacturer’s instructions for curing your prints, whether it be through heat curing or air drying, to ensure long-lasting and vibrant prints.

In conclusion, setting up a beginner screen printing machine can be a straightforward process if done correctly. By avoiding these common mistakes, you can ensure that your prints come out clean, vibrant, and professional-looking. Proper calibration, cleaning, ink selection, screen tension adjustment, and curing are all essential steps in the screen printing process that should not be overlooked. By following these guidelines, you can achieve successful printing results with your beginner screen printing machine.

Pre: How to Start Printing with an All-in-One Screen Printing Kit

Next: Choosing a Portable Small Screen Printing Machine for Events

Tags: