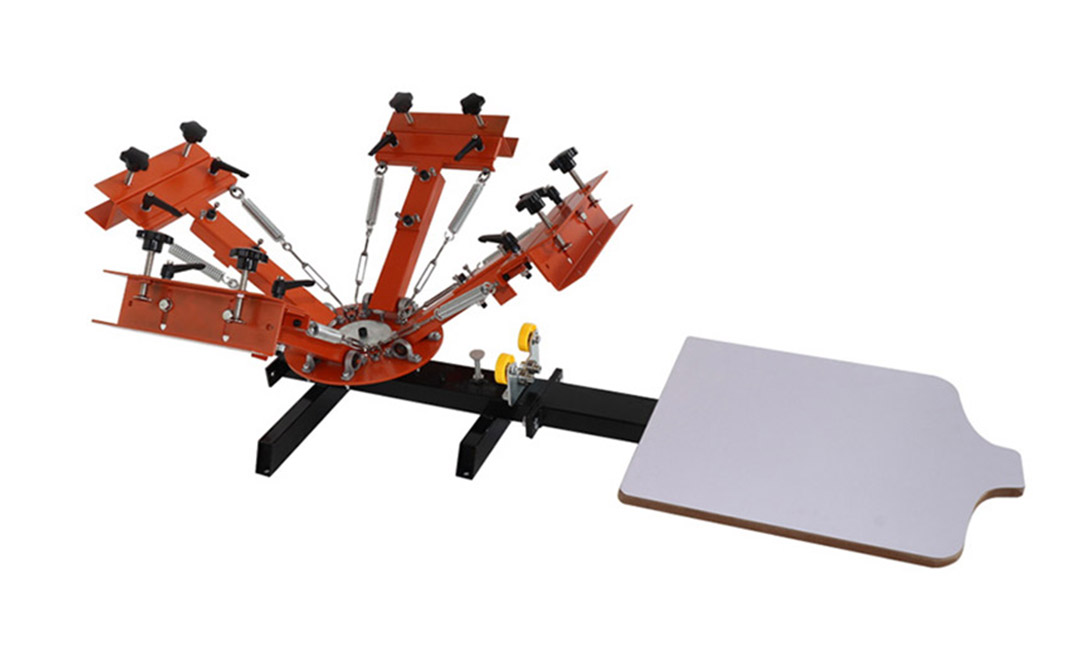

4 Color 1 Station Silk Screen Printing Machine: Tips for Beginners

Choosing the Right Mesh Count for Different Designs

Silk screen printing is a popular method of printing designs onto various surfaces, such as t-shirts, posters, and bags. One of the key factors in achieving a successful print is choosing the right mesh count for your design. The mesh count refers to the number of threads per inch on the screen, and it plays a crucial role in determining the level of detail and clarity in your print.

When starting out with a 4 color 1 station silk screen printing machine, it’s important to understand how different mesh counts can affect the outcome of your prints. Lower mesh counts, such as 110 or 156, are ideal for printing bold, solid designs with fewer details. These screens allow more ink to pass through, resulting in a thicker deposit of ink on the surface. This is perfect for designs that require a strong, opaque finish.

On the other hand, higher mesh counts, like 230 or 305, are better suited for intricate designs with fine details. These screens have smaller openings, which restrict the amount of ink that can pass through. This results in a more delicate and precise print, making it ideal for designs with small text or intricate patterns.

When choosing the right mesh count for your design, consider the level of detail and clarity you want to achieve. If you’re printing a simple logo or graphic with bold lines, a lower mesh count will suffice. However, if your design includes fine lines or small text, opt for a higher mesh count to ensure the details are captured accurately.

It’s also important to consider the type of ink you’ll be using when selecting a mesh count. Thicker inks, such as plastisol, require a lower mesh count to pass through the screen effectively. On the other hand, water-based or discharge inks work best with higher mesh counts to achieve a crisp, clean print.

Experimenting with different mesh counts is key to finding the right balance for your designs. Start by testing a few different mesh counts on scrap fabric or paper to see how each one affects the outcome. Pay attention to the level of detail, ink coverage, and overall clarity of the print to determine which mesh count works best for your specific design.

As you gain more experience with your 4 color 1 station silk screen printing machine, you’ll develop a better understanding of how different mesh counts can enhance your prints. Don’t be afraid to try new techniques and push the boundaries of your designs. With practice and patience, you’ll be able to create professional-quality prints that showcase your creativity and skill.

In conclusion, choosing the right mesh count is essential for achieving high-quality silk screen prints with your 4 color 1 station machine. Consider the level of detail in your design, the type of ink you’ll be using, and experiment with different mesh counts to find the perfect balance. With time and practice, you’ll be able to create stunning prints that stand out from the rest.

Proper Ink Mixing and Application Techniques

Silk screen printing is a popular method of printing designs onto various surfaces, such as t-shirts, posters, and bags. For beginners looking to get started with silk screen printing, one of the most important aspects to master is proper ink mixing and application techniques. In this article, we will discuss some tips to help beginners achieve the best results with their 4 color 1 station silk screen printing machine.

First and foremost, it is crucial to properly mix your ink before applying it to the screen. This ensures that the ink is evenly distributed and will result in a clean and crisp print. To mix your ink, start by placing a small amount of ink on a mixing palette. Use a spatula or palette knife to mix the ink until it reaches a smooth and consistent consistency. It is important to mix the ink thoroughly to avoid any clumps or streaks in your print.

Once your ink is properly mixed, it is time to apply it to the screen. To do this, place a small amount of ink at the top of the screen and use a squeegee to spread the ink evenly across the screen. Make sure to apply even pressure and use smooth, consistent strokes to ensure that the ink is evenly distributed. It is important to work quickly when applying the ink to prevent it from drying out and becoming difficult to work with.

When printing with multiple colors, it is important to clean the screen between each color to prevent any mixing of colors. To do this, use a clean rag or paper towel to wipe away any excess ink from the screen before applying the next color. This will help to ensure that each color remains crisp and vibrant in the final print.

In addition to proper ink mixing and application techniques, it is also important to consider the type of ink you are using. There are many different types of ink available for silk screen printing, each with its own unique properties and characteristics. It is important to choose the right ink for your project to achieve the best results. Water-based inks are a popular choice for beginners as they are easy to work with and clean up, while plastisol inks are more durable and long-lasting.

Finally, practice makes perfect when it comes to silk screen printing. The more you practice and experiment with different techniques, the better your prints will become. Don’t be afraid to make mistakes and learn from them. Silk screen printing is a skill that takes time and patience to master, but with practice and dedication, you can achieve professional-quality prints with your 4 color 1 station silk screen printing machine.

In conclusion, proper ink mixing and application techniques are essential for beginners looking to achieve the best results with their 4 color 1 station silk screen printing machine. By following these tips and practicing regularly, you can create high-quality prints that will impress your friends and customers. So don’t be afraid to dive in and start experimenting with silk screen printing today!

Troubleshooting Common Issues with Registration and Alignment

Silk screen printing is a popular method for creating high-quality prints on various surfaces, from t-shirts to posters. However, for beginners, mastering the art of registration and alignment can be a challenging task. The 4 Color 1 Station Silk Screen Printing Machine is a great tool for beginners to start their journey into silk screen printing. In this article, we will discuss some common issues that beginners may encounter when using this machine and provide tips on how to troubleshoot them.

One of the most common issues that beginners face when using a 4 Color 1 Station Silk Screen Printing Machine is registration errors. Registration refers to the alignment of the different colors in a design so that they line up perfectly on the final print. If the registration is off, the print will look blurry or misaligned, ruining the overall quality of the design.

To troubleshoot registration errors, start by checking the tightness of the screen clamps. Loose clamps can cause the screen to shift during printing, leading to registration issues. Make sure that the clamps are securely tightened before starting the printing process.

Another common cause of registration errors is improper screen tension. If the screen is too loose, it can stretch or warp during printing, causing the design to shift. To fix this issue, adjust the tension of the screen using the tension knobs on the machine. Make sure that the screen is taut and evenly tensioned before printing.

Additionally, check the alignment of the screens on the machine. Each screen should be positioned correctly in relation to the other screens to ensure proper registration. Use a ruler or a straight edge to align the screens before printing.

Ink smudging is another common issue that beginners may encounter when using a 4 Color 1 Station Silk Screen Printing Machine. Ink smudging occurs when the ink does not dry properly or when too much ink is applied to the screen. This can result in a messy print with blurred lines and smudges.

To troubleshoot ink smudging, start by adjusting the amount of ink applied to the screen. Use a squeegee to evenly distribute the ink across the screen, making sure not to apply too much pressure. Additionally, allow the ink to dry properly before removing the screen from the print surface. You can use a heat gun or a drying rack to speed up the drying process.

Another common issue that beginners may face is uneven ink coverage. Uneven ink coverage occurs when the ink does not spread evenly across the screen, resulting in patchy or streaky prints. This can be caused by improper squeegee technique or uneven screen tension.

To troubleshoot uneven ink coverage, start by adjusting the angle and pressure of the squeegee. Use a smooth, even motion to spread the ink across the screen, making sure to apply consistent pressure. Additionally, check the tension of the screen and adjust it as needed to ensure even ink coverage.

In conclusion, the 4 Color 1 Station Silk Screen Printing Machine is a great tool for beginners to start their journey into silk screen printing. By troubleshooting common issues such as registration errors, ink smudging, and uneven ink coverage, beginners can improve their printing skills and create high-quality prints. With practice and patience, beginners can master the art of silk screen printing and create stunning designs with their 4 Color 1 Station Silk Screen Printing Machine.

Pre: Top Advantages of 4 Color 1 Station Silk Screen Printing Machine

Next: Unlock Perfect Alignment with a 4 Color 1 Station Screen Printing Press with Micro Registration

Tags: